Structural insulation integrated precast concrete external wall panel and preparation process

A prefabricated concrete and structural thermal insulation technology, applied in thermal insulation, manufacturing tools, building components, etc., can solve the problems of low acceptance by developers, long prefabrication time, and high cost, shortening the demoulding time, cost saving, and reducing The effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

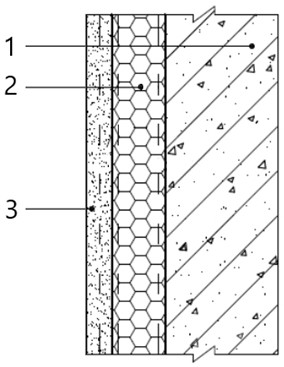

[0044] see figure 1 , figure 1 It is a schematic structural diagram of a prefabricated concrete exterior wall panel with integrated structure and thermal insulation provided in Embodiment 1 of the present invention.

[0045] A prefabricated concrete exterior wall panel with integrated structure and thermal insulation, comprising a concrete wall 1 arranged adjacent to each other in sequence, a thermal insulation panel 2 with high tensile strength and high bonding strength, high early strength and high thermal insulation panel 2 Mortar facing protection layer 3 with bonding strength;

[0046] One side of the insulation board 2 is self-bonded to the mortar facing protective layer 3 , and the other side is self-bonded to the concrete wall 1 .

[0047] Specifically, the insulation board 2 is polystyrene modified polystyrene board, which has good compatibility with cement-based materials, and its main performance indicators are as follows: compressive strength ≥ 0.3MPa, dry appare...

Embodiment 2

[0054] Different from Embodiment 1, this embodiment provides a prefabricated concrete exterior wall panel with integrated structure and thermal insulation, which also includes a plurality of connectors, and the thermal insulation board 2 and the concrete wall 1 are assisted by a plurality of connectors. Connection, the connecting piece is one or more of nylon plastic anchor bolts, stainless steel anchor bolts or anti-corrosion treated metal anchor bolts.

[0055] Among them, the number of connectors arranged per square meter of the wall is 4, the anchorage depth of the connectors in the concrete wall 1 is 30mm, and the standard value of the tensile bearing capacity of the connectors is 0.6kN.

[0056] On-site operations show that the tensile bonding strength of the prefabricated concrete exterior wall panels provided by Embodiment 1 and Embodiment 2, the mortar facing protective layer and the insulation layer can reach 0.20~0.30MPa, which ensures reliable bonding between layers...

Embodiment 3

[0058] A preparation process for prefabricated concrete exterior wall panels with integrated structural insulation, comprising:

[0059] Step 1. After setting up the formwork, fix the anti-corrosion treated steel wire mesh or alkali-resistant glass fiber mesh cloth in the formwork, then pour cement mortar and level it with vibration to obtain the mortar facing protective layer 3, wherein the mortar facing protection The 28d tensile bonding strength of layer 3 is greater than 0.2MPa, and the 1d compressive strength can reach more than 10MPa, which meets the operation requirements of 1d formwork removal of precast concrete exterior wall panels, and can realize decorative functions at the same time.

[0060] Step 2. Lay the thermal insulation board 2 above the mortar facing protective layer 3. The thermal insulation board 2 is self-bonded to the mortar facing protective layer 3. The thermal insulation board 2 is a silicon graphene modified polystyrene board, and its performance in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile bond strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com