Continuous production method of 3-mercaptopropionic acid alkyl ester and 3, 3'-trithiodipropionic acid dialkyl ester

A technology of dialkyl trithiodipropionate and dialkyl dithiodipropionate, which is applied in the field of fine chemicals, can solve the problem of large output of by-products of crystalline sodium thiosulfate, and achieve value-added design , strong combination flexibility and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare ammonium sulfide alkaline aqueous solution: add the ammonia solution (NH 3 The mass concentration is 5.8wt.%). Control the temperature of the ammonia solution at 3°C, and bubble 6.0 parts by mass of hydrogen sulfide gas into the ammonia solution within 30 minutes to obtain an alkaline aqueous solution of ammonium sulfide (pH≤9.5).

[0028] Add 100.0 parts by mass of dimethyl 3,3'-dithiodipropionate to the above alkaline aqueous solution of ammonium sulfide, keep the temperature of the mixture at 20°C, and pour it into the three-necked flask within 5 hours while stirring Slowly feed hydrogen sulfide with a mass fraction of 1.48. After static separation, an organic solution with about 101.4 parts by mass of the lower layer was obtained.

[0029] The organic solution was distilled under reduced pressure at 60° C. under nitrogen protection under a pressure of 2 mm Hg to obtain about 10.1 parts by mass of methyl 3-mercaptopropionate. After chromatographic analysis...

Embodiment 2

[0032]Preparation of potassium hydrosulfide alkaline aqueous solution: add 100.0 mass parts of potassium hydroxide aqueous solution (mass concentration of KOH is 19.1 wt.%) into a three-necked flask. Control the temperature of potassium hydroxide aqueous solution to be 50 DEG C, and in stirring state, in 30 minutes, in the potassium hydroxide aqueous solution, bubbling is passed into the hydrogen sulfide gas that is 15.5 mass parts, obtains the alkaline aqueous solution of potassium hydrogensulfide (pH≤9.5 ).

[0033] Add 100.0 parts by mass of dimethyl 3,3'-dithiodipropionate to the above alkaline aqueous solution of potassium hydrosulfide, keep the temperature of the mixture at 50°C under stirring, and transfer to the three-necked flask within 5 hours 2.3 mass parts of hydrogen sulfide were slowly introduced into the medium. After static separation, an organic solution of about 102.2 mass parts in the lower layer was obtained.

[0034] The organic solution was distilled un...

Embodiment 3

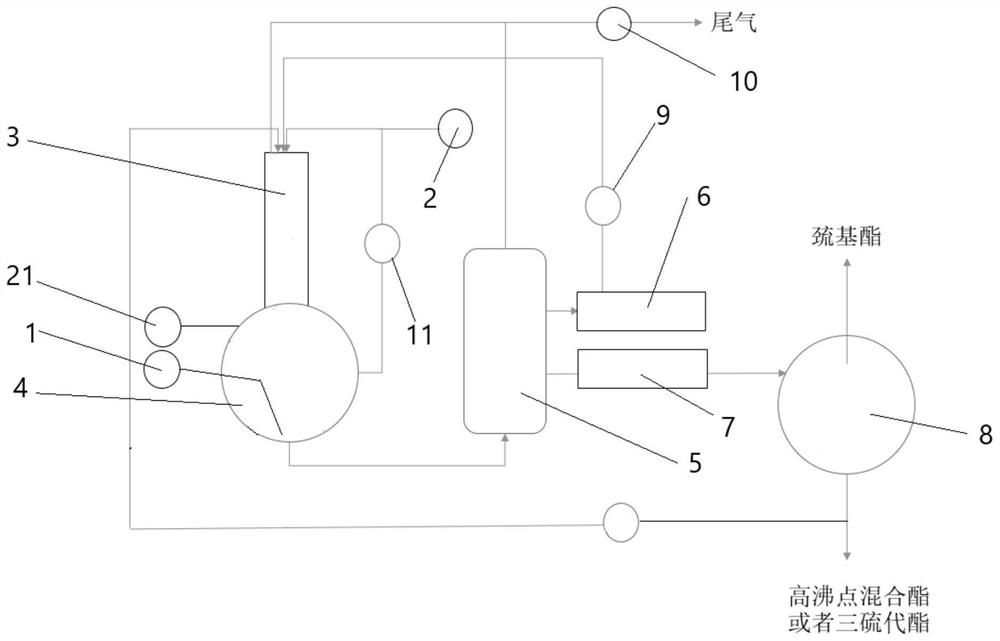

[0037] like figure 1 As shown, the continuous production of methyl 3-mercaptopropionate and dimethyl 3,3'-trithiodipropionate in this example is a diagram of the device. The device includes a feed unit, a reaction unit, a phase separation unit and a distillation unit The reaction unit includes a packed tower 3 and a reactor 4; the phase separation unit includes a first gravity separator 5, an aqueous phase storage tank 6 and an oil phase storage tank 7, and the reactor 4 in the reaction unit is connected with the first gravity separator 5 , the first gravity separator 5 is connected to the water phase storage tank 6 and the oil phase storage tank 7 respectively; the distillation unit is a vacuum still 8, which is connected to the oil phase storage tank 7.

[0038] The bottom liquid in the vacuum kettle 8 is connected to the top of the packed tower 3 through an infusion pump; the one-way liquid infusion device and the mass metering device 2 of the feeding unit are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com