Medium trace element fertilizer special for gramineous crops and preparation method and application thereof

A technology for medium and trace elements, grass crops, applied in application, fertilizer mixture, layered/coated fertilizer, etc., can solve the problems of poor degradation performance and environmental protection of polymer resin coating materials, achieve long degradation cycle, promote Dissolution release, high nutrient availability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

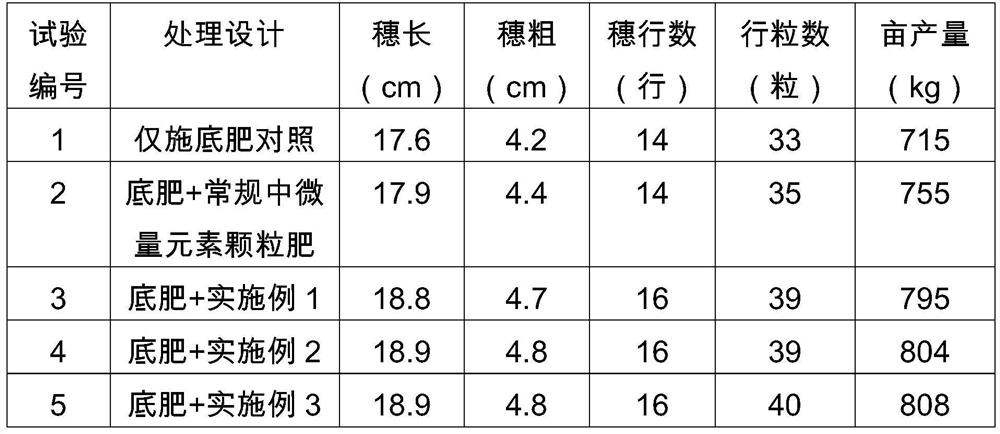

Examples

Embodiment 1

[0035] a) First, calcium hydroxide, calcium sulfate, magnesium hydroxide, magnesium carbonate, manganese carbonate, manganese hydroxide, zinc hydroxide, iron hydroxide, iron phosphate, and copper hydroxide inorganic compound raw materials are respectively pulverized to below 40 mesh.

[0036] b) The powder raw materials obtained by pulverizing in the previous stage are weighed in proportion. Calcium hydroxide 14 kg, calcium sulfate 10 kg, magnesium hydroxide 10 kg, magnesium carbonate 10 kg, manganese carbonate 5 kg, manganese hydroxide 5 kg, zinc hydroxide 5 kg, iron hydroxide 7 kg, iron phosphate 3 kg, 1 kg of copper hydroxide, mixed together evenly for later use.

[0037] c) Configure the binder solution.

[0038] Weigh 5 kg of PVA-1788 polyvinyl alcohol (polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 88%), slowly add 95 kg of water at 30°C, slowly stir to dissolve, and heat up to 40°C for 2 hours. After the polyvinyl alcohol is c...

Embodiment 2

[0044] a) First, calcium hydroxide, calcium sulfate, magnesium hydroxide, magnesium carbonate, manganese carbonate, manganese hydroxide, zinc hydroxide, iron hydroxide, iron phosphate, and copper hydroxide inorganic compound raw materials are respectively pulverized to below 40 mesh.

[0045] b) The powder raw materials obtained by pulverizing in the previous stage are weighed in proportion. Calcium hydroxide 10 kg, calcium sulfate 10 kg, magnesium hydroxide 8 kg, magnesium carbonate 10 kg, manganese carbonate 7 kg, manganese hydroxide 5 kg, zinc hydroxide 7 kg, iron hydroxide 10 kg, iron phosphate 5 kg, 3 kilograms of copper hydroxide, mix together and set aside.

[0046] c) Prepare the binder solution.

[0047] Weigh 5 kg of PVA-1788 polyvinyl alcohol, slowly add 95 kg of water at 30°C, slowly stir to dissolve, and raise the temperature to 40°C for 2 hours, and wait until the polyvinyl alcohol is completely dissolved for use;

[0048] Weigh 1 kg of xanthan gum, add 99 kg o...

Embodiment 3

[0053] a) First, calcium hydroxide, calcium sulfate, magnesium hydroxide, magnesium carbonate, manganese carbonate, manganese hydroxide, zinc hydroxide, iron hydroxide, iron phosphate, and copper hydroxide inorganic compound raw materials are respectively pulverized to below 40 mesh.

[0054] b) The powder raw materials obtained by pulverizing in the previous stage are weighed in proportion. Calcium sulfate 24 kg, magnesium carbonate 20 kg, manganese carbonate 12 kg, zinc hydroxide 6 kg, iron hydroxide 14 kg, copper hydroxide 2 kg, mix together and set aside.

[0055] c) Prepare the binder solution.

[0056] Weigh 5 kg of PVA-1788 polyvinyl alcohol, slowly add 95 kg of water at 30°C, slowly stir to dissolve, and raise the temperature to 40°C for 2 hours, and wait until the polyvinyl alcohol is completely dissolved for use;

[0057] Weigh 1 kg of xanthan gum, add 99 kg of water at 30°C, slowly stir to dissolve, and heat up to 40°C for 1 hour, and wait for the xanthan gum to di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com