A kind of microcrystalline waterproofing agent for concrete and its application

A waterproofing agent and concrete technology, which is applied in the field of concrete additives, can solve the problems of poor bonding, cracks on the plugging surface, and the overall shedding of the waterproof layer wall, and achieve the effects of good dispersion and retention, enhanced defoaming, and enhanced waterproofing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

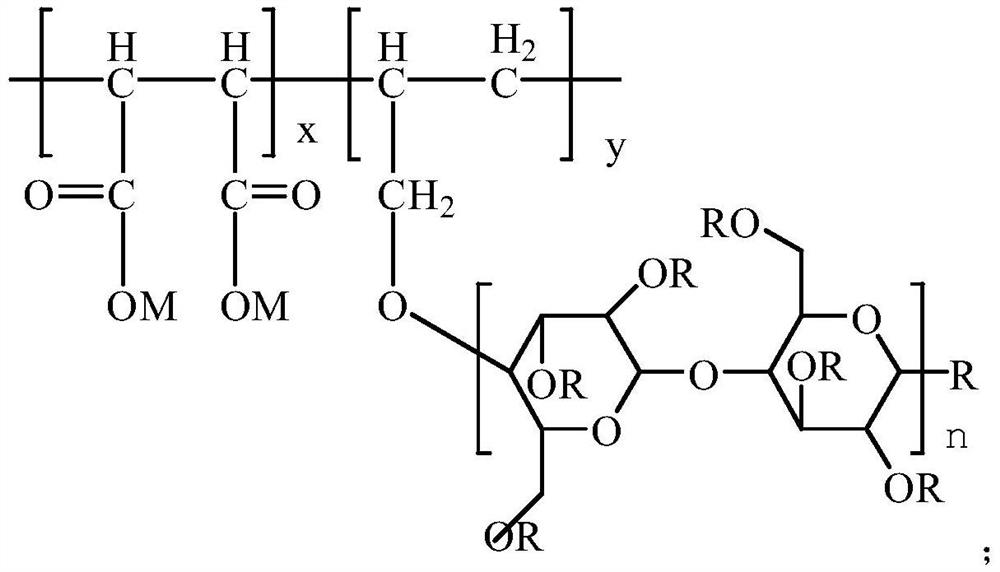

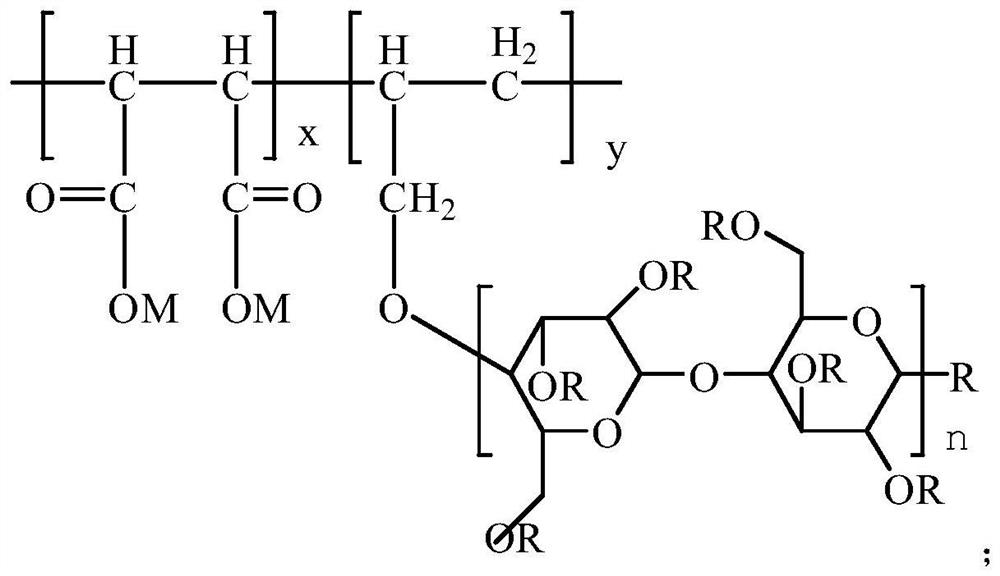

Image

Examples

Embodiment 1

[0038] A kind of application of microcrystalline waterproofing agent for concrete as concrete additive, and its preparation method comprises the steps:

[0039] Step 1. Modification of silica particles: drying the silica particles in a muffle furnace, then uniformly dispersing in the added absolute ethanol, and then adding γ-mercapto which accounts for 27% of the total mass of the silica particles propyltriethoxysilane, heated to 55°C under low pressure, stirred for 3h, and finally the mixture was filtered, dried and ground. The microcrystalline particle size of the modified silica powder is larger than 400 meshes, and the specific surface is 210-250 cm 2 / g.

[0040] Step 2. Weigh 2kg of defoamer, 4kg of modified silica powder and 1kg of water reducing agent according to the formula, then mix the defoaming agent, modified silica powder waterproofing agent and water reducing agent to 60°C and heat up to 60°C. Stir for 30min to obtain component A; then mix 600kg of concrete (...

Embodiment 2

[0045] A kind of application of microcrystalline waterproofing agent for concrete as additive, the preparation method of which comprises the following steps:

[0046] Step 1. Modification of silica particles: drying the silica particles in a muffle furnace, then uniformly dispersing in the added absolute ethanol, and then adding γ-mercapto which accounts for 15% of the total mass of the silica particles propyltriethoxysilane, heated to 45°C under low pressure, stirred for 5h, and finally the mixture was filtered, dried and ground. The microcrystalline particle size of the modified silica powder is larger than 400 meshes, and the specific surface is 210-250 cm 2 / g.

[0047] Step 2. Weigh 1kg of defoamer, 2kg of modified silica powder and 0.5kg of water reducing agent according to the formula, then mix the defoaming agent, modified silica powder waterproofing agent and water reducing agent to 60°C, And stir for 30min to obtain component A; then mix 1000kg of concrete (the mas...

Embodiment 3

[0053] A kind of microcrystalline waterproofing agent for concrete is used as the application that should be a bulk concrete additive, and its preparation method comprises the following steps:

[0054] Step 1. Modification of silica particles: drying the silica particles in a muffle furnace, then uniformly dispersing in the added absolute ethanol, and then adding γ-mercapto which accounts for 40% of the total mass of the silica particles propyltriethoxysilane, heated to 60°C under low pressure, stirred for 2h, and finally the mixture was filtered, dried and ground. The microcrystalline particle size of the modified silica powder is larger than 400 meshes, and the specific surface is 210-250 cm 2 / g.

[0055] Step 2. Weigh 5kg of defoamer, 4kg of modified silica powder and 1.5kg of water reducing agent according to the formula, then mix the defoamer, modified silica powder waterproofing agent and water reducing agent to 60°C, And stir 30min, obtain component A; Then mix 500kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com