Method for repairing fiber-reinforced resin-based composite material

A fiber-reinforced resin and composite material technology, applied in the field of sustainable application of advanced composite materials, can solve the problems of high heating temperature, poor compactness of the repair layer, complicated operation process, etc., and achieve high degree of bonding, good compactness, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

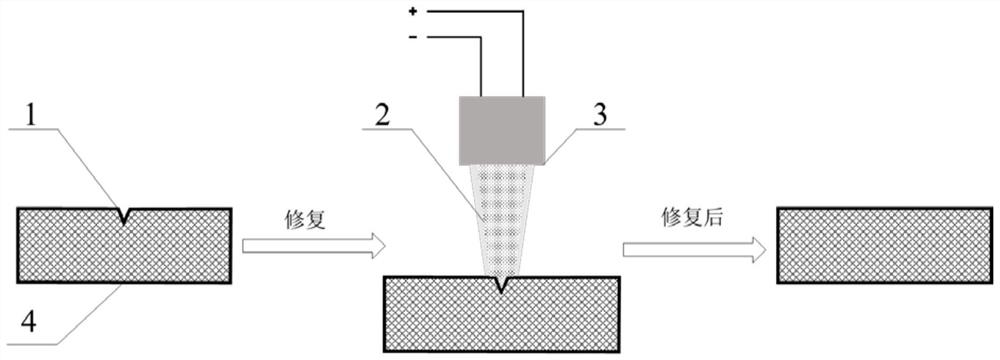

[0033] This example provides a fiber-reinforced resin-based composite material repair method for the type of cracking and damage to the PEEK resin matrix during the use of carbon fiber-reinforced PEEK composite materials, such as figure 1 As shown, it specifically includes the following steps:

[0034] Step 1. Use an ultrasonic detection device to detect the carbon fiber reinforced PEEK composite material 4, determine the type and distribution of the damaged area, and mark the damaged area; prepare PEEK powder with a particle size of 20 μm according to the damage type of the PEEK resin matrix cracking 1 Body 2.

[0035] Step 2: Use a high-pressure air gun to clean the cracked 1 area of the PEEK resin matrix to remove debris and dust in the cracked 1 area of the PEEK resin matrix.

[0036]Step 3: Spray a small amount of quartz sand on the crack 1 area of the PEEK resin matrix to enhance the bonding strength of the interface between the PEEK powder 2 and the carbon fiber ...

Embodiment 2

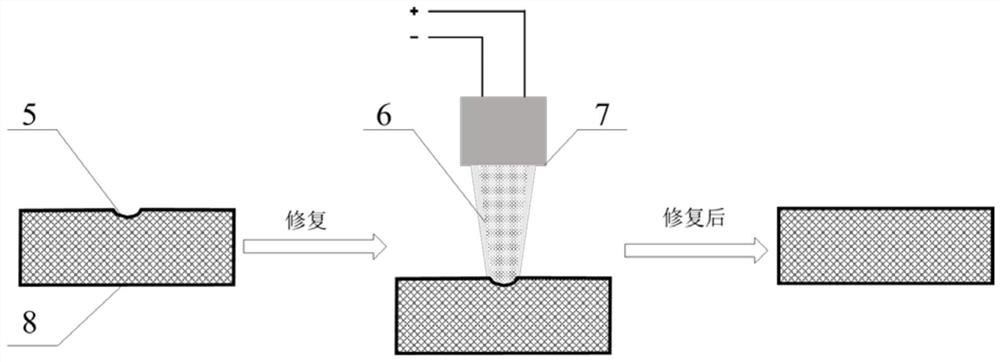

[0040] This example provides a fiber-reinforced resin-based composite material repair method for the type of notch damage in the use of carbon fiber-reinforced PEEK composite materials, such as figure 2 As shown, it specifically includes the following steps:

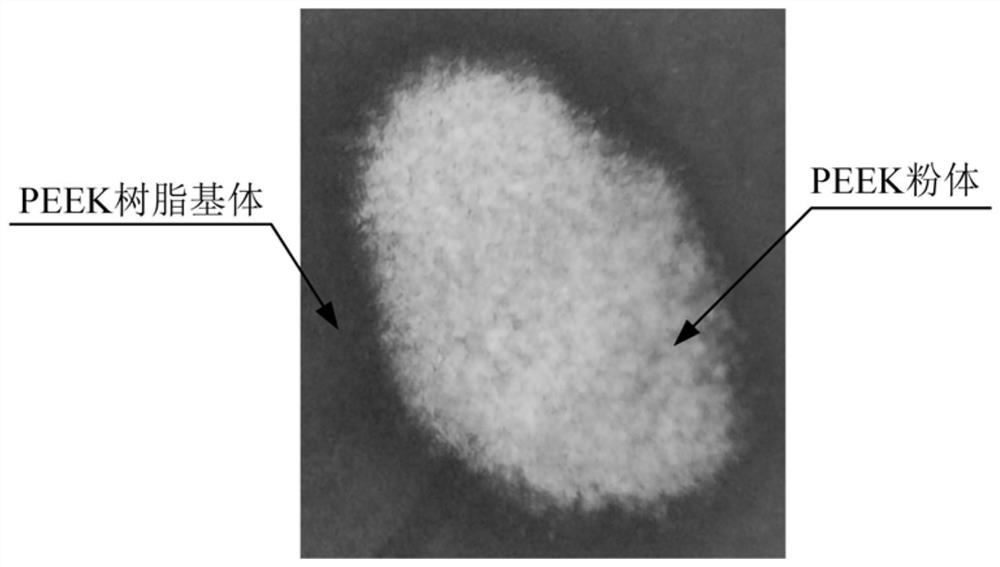

[0041] Step 1. Use an ultrasonic detection device to detect the carbon fiber reinforced PEEK composite material 8, determine the type and distribution of the damaged area, and mark the damaged area; for the damage type of the gap 5, prepare a fiber reinforced resin-based composite material powder; The preparation method of the reinforced resin-based composite material powder is as follows: carbon fiber, PEEK, and ethyl silicate are mixed and granulated, and then finely pulverized to form a carbon fiber-reinforced PEEK composite material powder 6 with a particle size of 25 μm.

[0042] Among them, other preparation methods of fiber-reinforced resin-based composite material powder can be selected according to repair requi...

Embodiment 3

[0048] This embodiment provides a method for repairing fiber-reinforced resin-based composite materials for the type of carbon fiber fracture damage during the use of carbon fiber-reinforced PEEK composite materials, which specifically includes the following steps:

[0049] Step 1. Use an ultrasonic testing device to detect the carbon fiber reinforced PEEK composite material, determine the type and distribution of the damaged area, and mark the damaged area; prepare carbon fiber powder with a particle size of 25 μm according to the type of carbon fiber fracture damage.

[0050] Step 2: Use a high-pressure air gun to clean the carbon fiber fracture area to remove debris and dust in the carbon fiber fracture area.

[0051] Step 3: Spray a small amount of quartz sand in the carbon fiber fracture damage area to enhance the bonding strength of the interface between the carbon fiber powder and the carbon fiber reinforced PEEK composite material.

[0052] Step 4. When the gas tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com