Planking mark stud welding process

A technology of marking and planting welding, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., to achieve the effect of improving welding accuracy and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

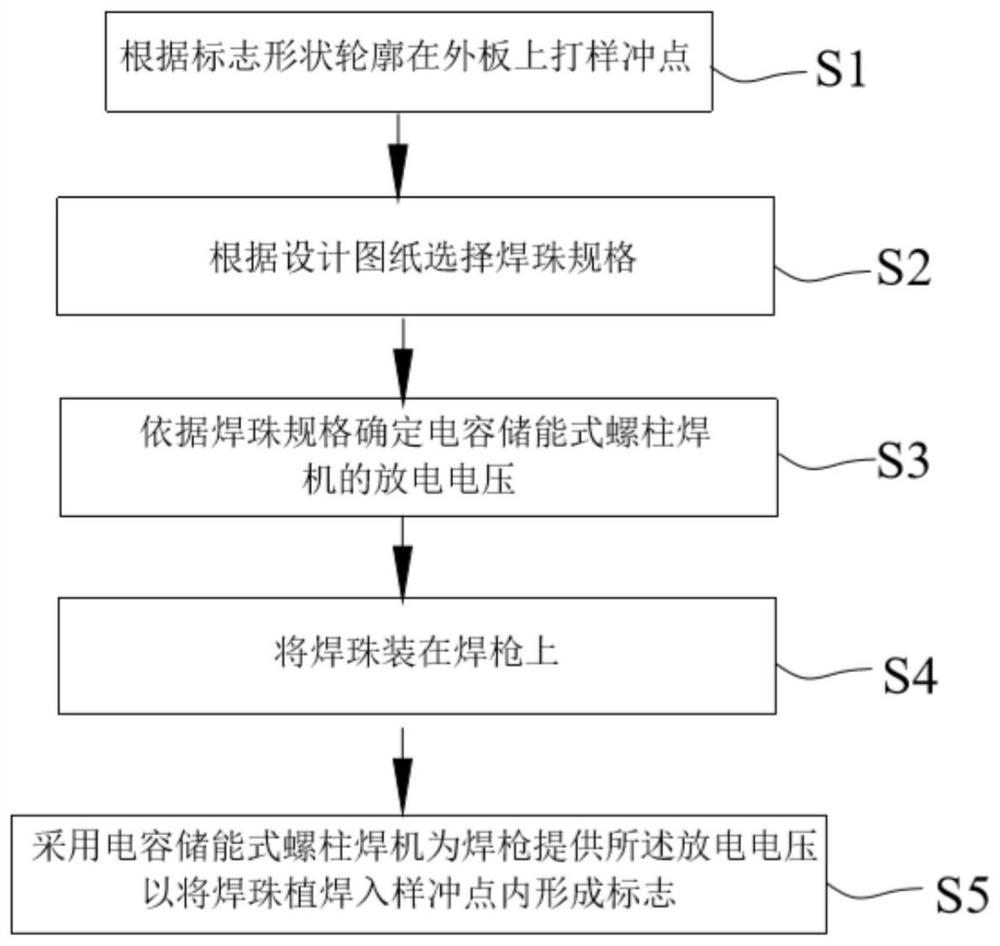

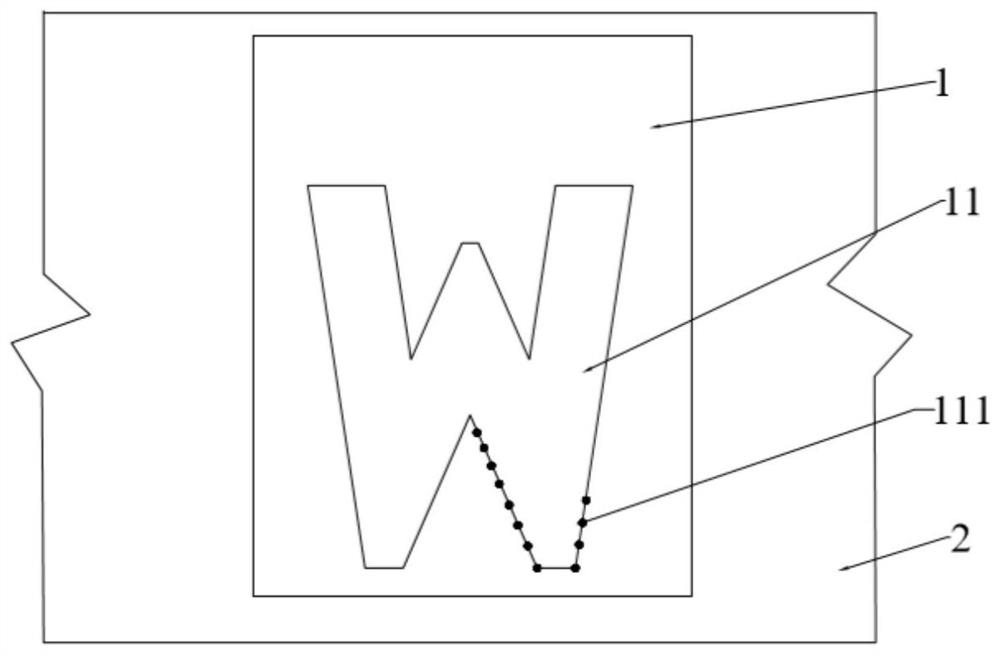

[0043] This embodiment discloses a kind of planting and welding process of the outer plate mark, such as Figure 1-Figure 4 As shown, the implant welding process of the outer plate logo includes the following steps:

[0044] S1. According to the shape outline 11 of the logo, make a sample punch on the outer plate 2;

[0045] S2. Select welding bead specifications according to the design drawings;

[0046] S3. Determine the discharge voltage of the capacitor energy storage stud welding machine according to the welding bead specification;

[0047] S4, the welding beads are installed on the welding torch;

[0048] S5. Using a capacitor energy storage type stud welding machine to provide the discharge voltage to the welding torch, so as to weld the welding beads into the sample punching point to form a mark.

[0049] The outer plate sign planting welding process of the present invention overcomes the existing CO 2 Defects such as arc craters and shrinkage cavities caused by se...

Embodiment 2

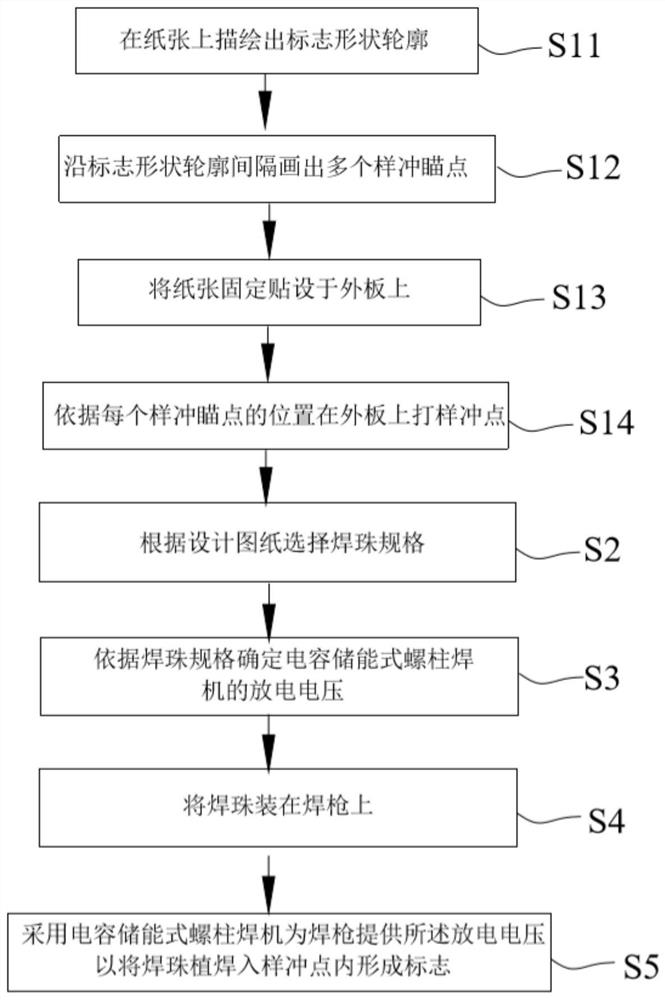

[0073] This embodiment discloses a planting and welding process for signs on the outer plate. In this embodiment, the same parts as those in Embodiment 1 are given the same reference numerals, and the same text descriptions are omitted.

[0074] Figure 5 It is a detailed step-by-step flow chart of an outer plate sign planting welding process provided by an embodiment of the present invention, as shown in Figure 5 As shown, with respect to Embodiment 1, the outer panel mark planting welding process provided by this embodiment has such a difference: the above-mentioned step S1 specifically includes:

[0075] S11, draw the logo shape outline 11 on the outer plate 2;

[0076] S12. Draw a plurality of sample punching points 111 at intervals along the outline of the logo shape 11;

[0077] S13. Make a sample punch point at the position of each sample punch point 111.

[0078] By first drawing the outline of the logo shape 11 on the outer plate 2, then drawing a plurality of sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com