Ibuprofen-loaded menthol composite particle and preparation method thereof

A technology of composite particles and menthol, which is applied in the field of composites, can solve the problems of unfavorable industrial production application, unfavorable industrial production application, and the use of more auxiliary materials, etc., and achieve the effects of preventing agglomeration, good fluidity, and excellent filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) At 40°C, prepare a mixed aqueous solution containing 0.01g / mL ibuprofen and 0.01g / mL menthol;

[0039] (2) Stir the mixed solution in (1) until liquid-liquid phase separation occurs and the ibuprofen-menthol oil droplets are evenly distributed in the water;

[0040] (3) Keep stirring to cool the solution to 1°C at a cooling rate of 30°C / 10min, and keep stirring at 0.143kW / m 3 until crystallization;

[0041] (4) adding a mass fraction of 0.02% surfactant sodium stearate, and continuously stirring for 0.5h, the crystals are coalesced into compact spheres;

[0042] (5) After vacuum filtration, washing with water, and drying at normal pressure at 15° C. for 12 hours, the ibuprofen-loaded menthol functional granules were obtained.

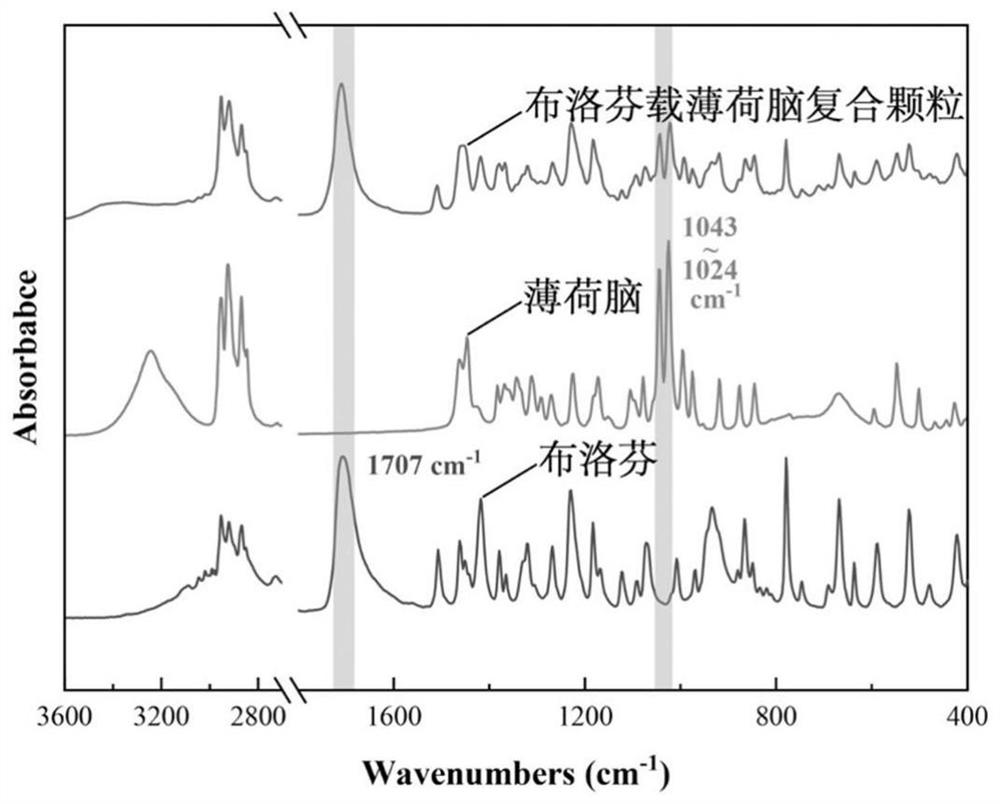

[0043] The solid infrared absorption spectrum of product (instrument model ALPHA, Bruker, Germany) sees figure 1 , the infrared spectrum of the product is at 1707cm -1 The absorption peak of ibuprofen appears at 1043-1024cm -1 There is a...

Embodiment 2

[0046] (1) At 60°C, prepare a mixed aqueous solution containing 0.025g / mL ibuprofen and 0.05g / mL menthol;

[0047] (2) Stir the mixed solution in (1) until liquid-liquid phase separation occurs and the ibuprofen-menthol oil droplets are evenly distributed in the water;

[0048] (3) Keep stirring to cool the solution to 5°C at a cooling rate of 45°C / 10min, and keep stirring at 0.268kW / m 3 until crystallization;

[0049] (4) adding the surfactant sodium hexametaphosphate with a mass fraction of 0.10%, and continuously stirring for 1.5 hours, so that the crystals are coalesced into compact spheres;

[0050] (5) After vacuum filtration, washing with water, and drying at normal pressure at 15° C. for 24 hours, the ibuprofen-loaded menthol functional granules were obtained.

[0051] According to the solid infrared absorption spectrum result of product (testing method is the same as embodiment 1), judge product is the physical mixture of ibuprofen and menthol, and both all exist wi...

Embodiment 3

[0053] (1) At 70°C, prepare a mixed aqueous solution containing 0.15g / mL ibuprofen and 0.10g / mL menthol;

[0054] (2) Stir the mixed solution in (1) until liquid-liquid phase separation occurs and the ibuprofen-menthol oil droplets are evenly distributed in the water;

[0055] (3) Keep stirring to cool the solution to 7°C at a cooling rate of 60°C / 10min, and keep stirring at 0.588kW / m 3 until crystallization;

[0056] (4) adding a surfactant sodium dodecylbenzenesulfonate with a mass fraction of 0.30%, and stirring continuously for 3.5 hours, so that the crystals are coalesced into compact spheres;

[0057] (5) After vacuum filtration, washing with water, and drying at normal pressure at 20° C. for 36 hours, the ibuprofen-loaded menthol functional granules were obtained.

[0058] According to the solid infrared absorption spectrum result of product (testing method is the same as embodiment 1), judge product is the physical mixture of ibuprofen and menthol, and both all exist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com