Method for increasing yield of 5-aminolevulinic acid synthesized by corynebacterium glutamicum

A technology of Corynebacterium glutamicum and aminolevulinic acid, which is applied in the field of bioengineering, can solve the problems of low 5-ALA, complex medium components, and expensive 5-aminolevulinic acid, and achieve high yield and optimized fermentation conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

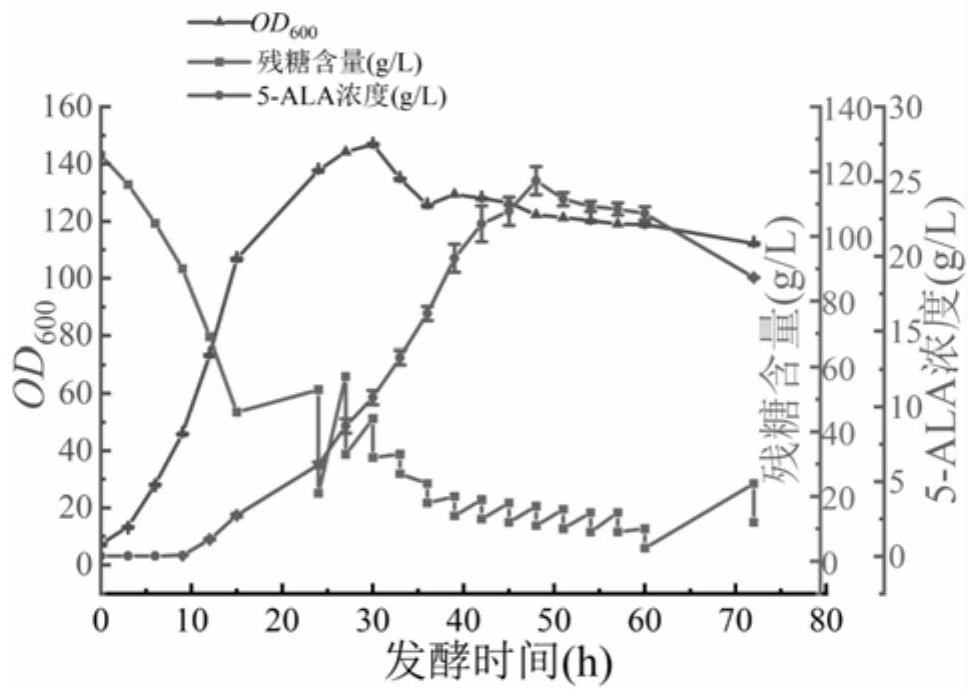

Examples

Embodiment 1

[0055] Example 1: Construction of Corynebacterium glutamicum C1 knocking out α-ketoglutarate inhibitory protein odhI

[0056] Specific steps are as follows:

[0057] (1) With the genomic DNA of Corynebacterium glutamicum ATCC13032 as a template, with odhI F1 (sequence shown in SEQ ID NO.7) and R1 (sequence shown in SEQ ID NO.8), odhI F2 (sequence shown in SEQ ID NO.8) NO.9) and R2 (sequence shown in SEQ ID NO10) were used as primers to amplify the upstream and downstream two homologous arms of about 500 bp each, perform fusion extension PCR, purify and recover the gene fragment and digest it with the pK18 plasmid The obtained linearized product was ligated by DNA ligase, and the ligated product was introduced into E.coli BL21 competent cells by chemical transformation method, cultured on Kan-resistant BHI plate, picked a single colony and transferred to LB medium, and the bacterial liquid was taken Extract the recombinant plasmid pK18-△odhI, sequence pk18-△odhI, and compare t...

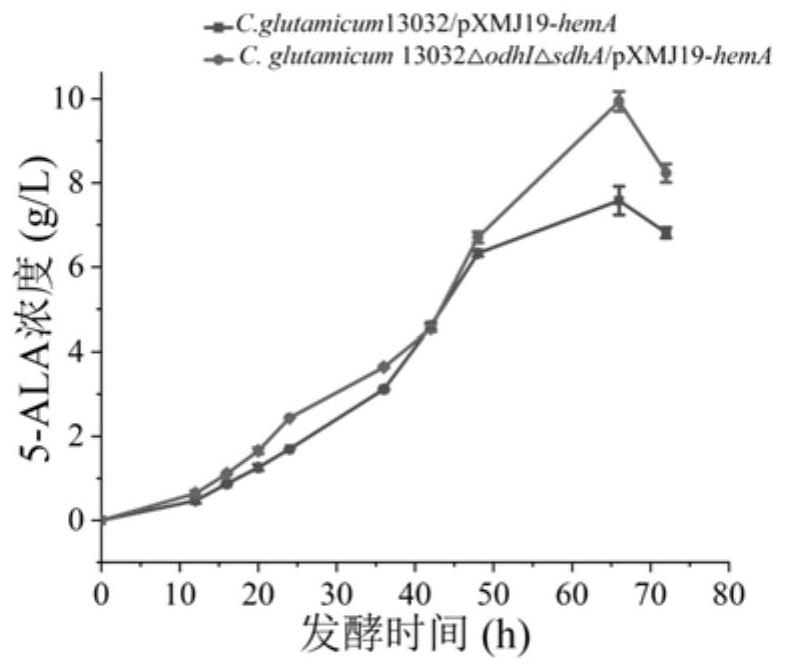

Embodiment 2

[0059] Example 2: Construction of recombinant Corynebacterium glutamicum knocking out succinate dehydrogenase sdhA

[0060] Specific steps are as follows:

[0061] (1) Using the genomic DNA of Corynebacterium glutamicum ATCC13032 / pK18-△odhI constructed in Example 1 as a template, with sdhA F1 (sequence shown in SEQ ID NO.11) and R1 (sequence shown in SEQ ID NO.11) NO.12), sdhA F2 (sequence shown in SEQ ID NO.13) and R2 (sequence shown in SEQ ID NO.14) were used as primers to amplify the upstream and downstream two homologous arms of about 500bp each, Fusion extension PCR was performed to obtain a 2200bp gene fragment, which was connected to the pK18mobsacB vector to obtain pk18-△sdhA. The pk18-△sdhA was sequenced and compared by DNAMAN. The results showed that the gene sequence was correct.

[0062] (2) Transfer the recombinant plasmid pk18-△sdhA to Corynebacterium glutamicum ATCC13032 / pK18-△odhI by electroporation to obtain transformants, then expand the prepared transforman...

Embodiment 3

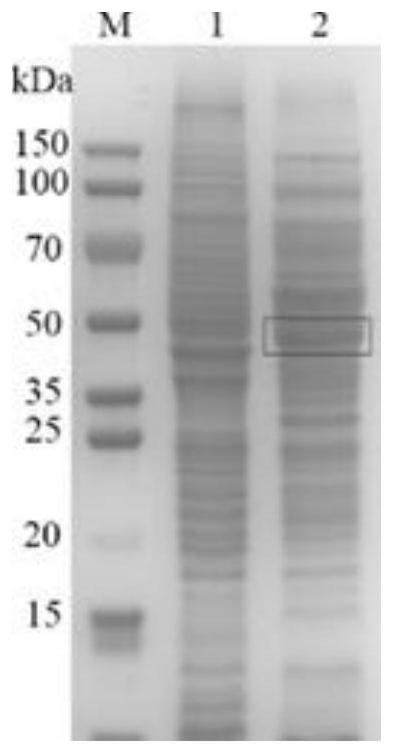

[0063] Example 3: Cloning and expression of 5-aminolevulinic acid synthase hemA in Corynebacterium glutamicum strain C. glutamicum 13032-△odhI△sdhA

[0064] Specific steps are as follows:

[0065] (1) Construction of recombinant plasmids

[0066] The gene hemA (Genebank: AY489557.1) sequence derived from Rhodopseudomonas palustris was synthesized in Suzhou Jinweizhi Biological Co., Ltd.

[0067] Using the synthesized recombinant plasmid containing the target gene as a template, using primers hemA-F and hemA-R respectively, the target gene fragment hemA fragment was obtained by PCR amplification, and the obtained hemA fragment and pXMJ19 plasmid were double-digested with HindIII and EcoRI and After ligation, the recombinant plasmid was obtained, and the recombinant plasmid was transformed into Escherichia coli BL21, the positive transformant was picked to extract the plasmid, and the plasmid was used as a template for PCR verification. The results showed that the plasmid pXMJ1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com