Method for directionally producing aromatic hydrocarbon-rich bio-oil and hydrogen-rich biomass gas

A biogas and bio-oil technology, which is applied in the preparation of liquid hydrocarbon mixtures, processing hydrocarbon oil, biofuels, etc., can solve the problems of low hydrogen selectivity, low utilization rate, and low selectivity of aromatics, and achieve hydrogen selectivity High efficiency, reduced process cost, and high selectivity of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

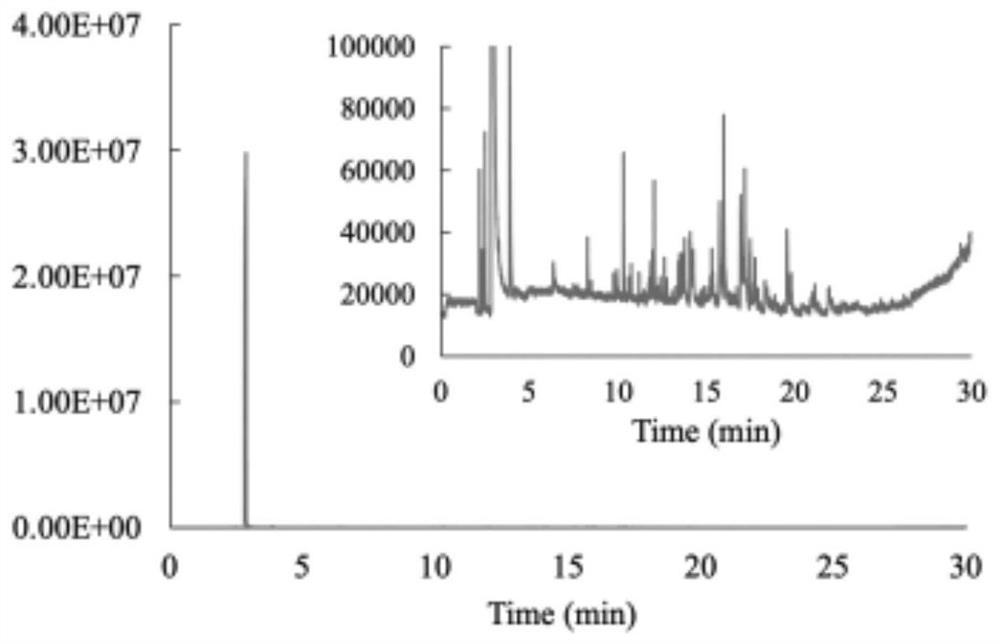

Image

Examples

Embodiment 1

[0039] Embodiment 1. A method for directional production of aromatics-rich bio-oil and hydrogen-rich biomass gas

[0040] S1 Take 100g of chestnut shells, clean the chestnut shells, place them at 105°C to dry to constant weight, and crush them to obtain chestnut shell powder. At room temperature, soak the chestnut shell powder in 85 wt. Heat to 80°C and continue to soak for 12 hours. In the step S1, the solid-to-liquid ratio of chestnut shell powder and phosphoric acid solution is 1g:0.94ml. After soaking, place it at 105°C to dry to constant weight, and place it in a ventilated place at room temperature for 12 hours;

[0041] S2 pyrolyzes the chestnut shell powder processed in step S1 in a high-temperature tube furnace, uses high-purity nitrogen to ventilate at a flow rate of 1000mL / min for 15 minutes to remove oxygen in the system, sets the pyrolysis temperature to 850°C, and the reaction time is 30 minutes. During the reaction process, the nitrogen flow rate was adjusted to...

Embodiment 2

[0043] Embodiment 2. A method for directional production of aromatics-rich bio-oil and hydrogen-rich biomass gas

[0044] S1 Take 100g of chestnut shells, clean the chestnut shells, place them at 105°C to dry to constant weight, and crush them to obtain chestnut shell powder. At room temperature, soak the chestnut shell powder in 85 wt. Heat to 75°C and continue to soak for 12 hours. The solid-to-liquid ratio of chestnut shell powder and phosphoric acid solution in step S1 is 1g:0.70ml. After soaking, place it at 105°C to dry to constant weight, and place it in a ventilated place at room temperature for 12 hours;

[0045] S2 pyrolyzes the chestnut shell powder processed in step S1 in a high-temperature tube furnace, uses high-purity nitrogen to ventilate at a flow rate of 1000mL / min for 15 minutes to remove oxygen in the system, sets the pyrolysis temperature to 850°C, and the reaction time is 30 minutes. During the reaction process, the nitrogen flow rate was adjusted to 75mL...

Embodiment 3

[0047] Embodiment 3. A method for directional production of aromatics-rich bio-oil and hydrogen-rich biomass gas

[0048] S1 Take 100g of chestnut shells, clean the chestnut shells, place them at 105°C to dry to constant weight, and crush them to obtain chestnut shell powder. At room temperature, soak the chestnut shell powder in 85 wt. Heat to 85°C and continue to soak for 12 hours. The solid-to-liquid ratio of chestnut shell powder and phosphoric acid solution in step S1 is 1g:0.94ml. After soaking, place it at 105°C to dry to constant weight, and place it in a ventilated place at room temperature for 12 hours;

[0049] S2 pyrolyzes the chestnut shell powder processed in step S1 in a high-temperature tube furnace, uses high-purity nitrogen to ventilate at a flow rate of 1000mL / min for 15 minutes to remove oxygen in the system, sets the pyrolysis temperature to 950°C, and the reaction time is 25 minutes. During the reaction process, the nitrogen flow rate was adjusted to 75mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com