Wear-resistant ceramic material and application thereof in pump body repair

A technology of wear-resistant ceramics and wear-resistant agent, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of shortened service life of equipment, complicated processes, accelerated equipment corrosion, etc. The investment of equipment, simple construction process and the effect of prolonging the service life

Pending Publication Date: 2021-06-18

QINGDAO COPON NEW MATERIAL TECH CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, after a certain number of years of normal use of the water pump, due to electrochemical corrosion, oxidation-reduction reactions occur on the corroded metal electrodes, and small hole corrosion, crevice corrosion, and intergranular corrosion occur. The water pump cavity and impeller will wear to varying degrees, which will accelerate the damage of the equipment and the use of the equipment. The shortened service life will bring safety hazards to the normal operation of the equipment, and the corrosion of the equipment will be accelerated under such working conditions, and the efficiency of the water pump will decrease and the energy consumption will increase. Usually, the repair of the water pump can only be done by replacing accessories and equipment, which takes a long time to repair and is expensive

[0003] CN102527618A discloses a method for repairing and coating waste water pumps, which includes the following steps: (1) Preparatory work: first build a heat preservation shed, then derust the painted surface of the waste pump body until the fresh metal surface is completely exposed, and finally, make the waste water pump The pump body and the heat preservation shed reach 20-30°C; (2) Repair the diaphragm of the used pump body; (3) Repair the joint surface of the pump body and the sealing ring of the used pump body; (4) Repair the middle opening of the used pump body (5) Partial reinforcement of the waste pump body; (6) Repair coating of the flow channel of the waste pump body. This invention can use different combinations of paints according to different damaged parts, effectively improving the cavitation wear resistance of the water pump. And it can greatly improve the performance of the water pump and save electric energy, but the repair process of this invention is complicated and time-consuming, and the bonding force between the surface coating and the substrate after repair is poor, and the wear resistance cannot be guaranteed

[0004] At present, after a certain number of years of normal use of the water pump, due to the characteristics of different fluids, the water pump cavity and impeller will wear to varying degrees, which not only brings safety hazards to the normal operation of the equipment, but also reduces the efficiency of the water pump under such working conditions and increases energy consumption. In order to solve the above The problem is that most companies replace accessories and equipment, and the investment in equipment is relatively large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

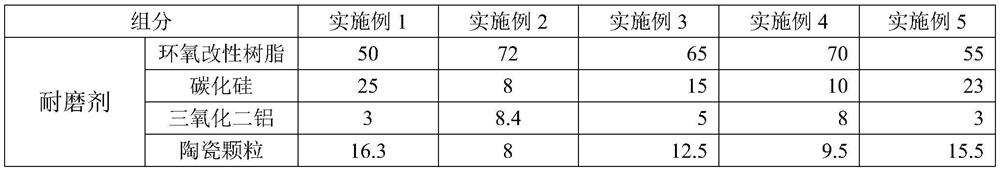

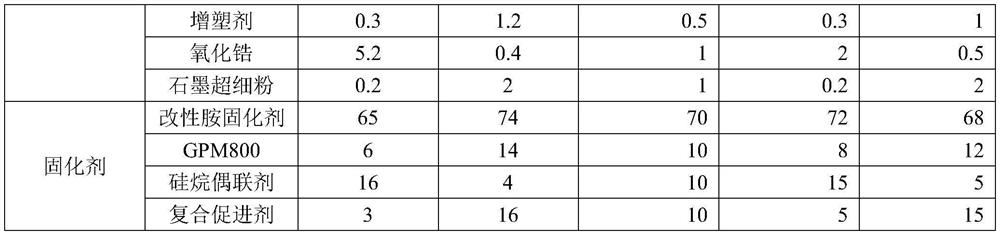

[0045] Embodiment 1-5 A kind of wear-resistant ceramic material

[0046] The compositions and dosages of the wear-resistant ceramic materials described in Examples 1-5 are shown in Table 1.

[0047] Table 1

[0048]

[0049]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a wear-resistant ceramic material and application thereof in pump body repair, the wear-resistant ceramic material comprises a wear-resistant agent and a curing agent, the wear-resistant agent comprises, by weight, 50-72 parts of epoxy modified resin, 8-25 parts of silicon carbide, 3-8.4 parts of aluminum oxide, 8-16.3 parts of ceramic particles, 0.3-1.2 parts of a plasticizer, 0.4-5.2 parts of zirconium oxide and 0.2-2 parts of graphite powder. The curing agent is prepared from 65-74 parts of modified amine curing agent, 6-14 parts of GPM800, 4 -16 parts of silane coupling agent and 3 -16 parts of composite accelerant. A hydrophobic ceramic layer can be formed on the surface of the water pump through the combined action of the wear-resistant agent and the curing agent, the roughness is reduced while the strength of the treated part of the water pump is improved, and the energy-saving effect is achieved. The service life of the pump repaired through the method can be prolonged to 4-6 years, and the reliability of equipment operation is improved.

Description

technical field [0001] The invention relates to the technical field of water pump repair, in particular to a wear-resistant ceramic material and its application in pump body repair. Background technique [0002] The water pump is mainly used for the transportation of various fluids and the cooling of equipment in the circulation system. Its energy consumption accounts for about 20% of the electricity consumption of the entire production plant. The safety and reliability of power equipment is related to the normal operation of the entire production. At present, after a certain number of years of normal use of the water pump, due to electrochemical corrosion, oxidation-reduction reactions occur on the corroded metal electrodes, and small hole corrosion, crevice corrosion, and intergranular corrosion occur. The water pump cavity and impeller will wear to varying degrees, which will accelerate the damage of the equipment and the use of the equipment. The shortened service life w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L63/00C08K13/02C08K3/34C08K3/22C08K3/013C08K3/04F04D29/02

CPCC09D163/00C09D5/08C09D7/61F04D29/026C08K2003/2227C08K2003/2244Y02P20/10

Inventor 王立民

Owner QINGDAO COPON NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com