Preparation method of lignin chelated stannous hydrogel

A technology of lignin and hydrogel, which is applied in the field of preparation of lignin chelated stannous hydrogel, can solve the environmental impact of tin and other problems, and achieve the effects of short time consumption, simple extraction method, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

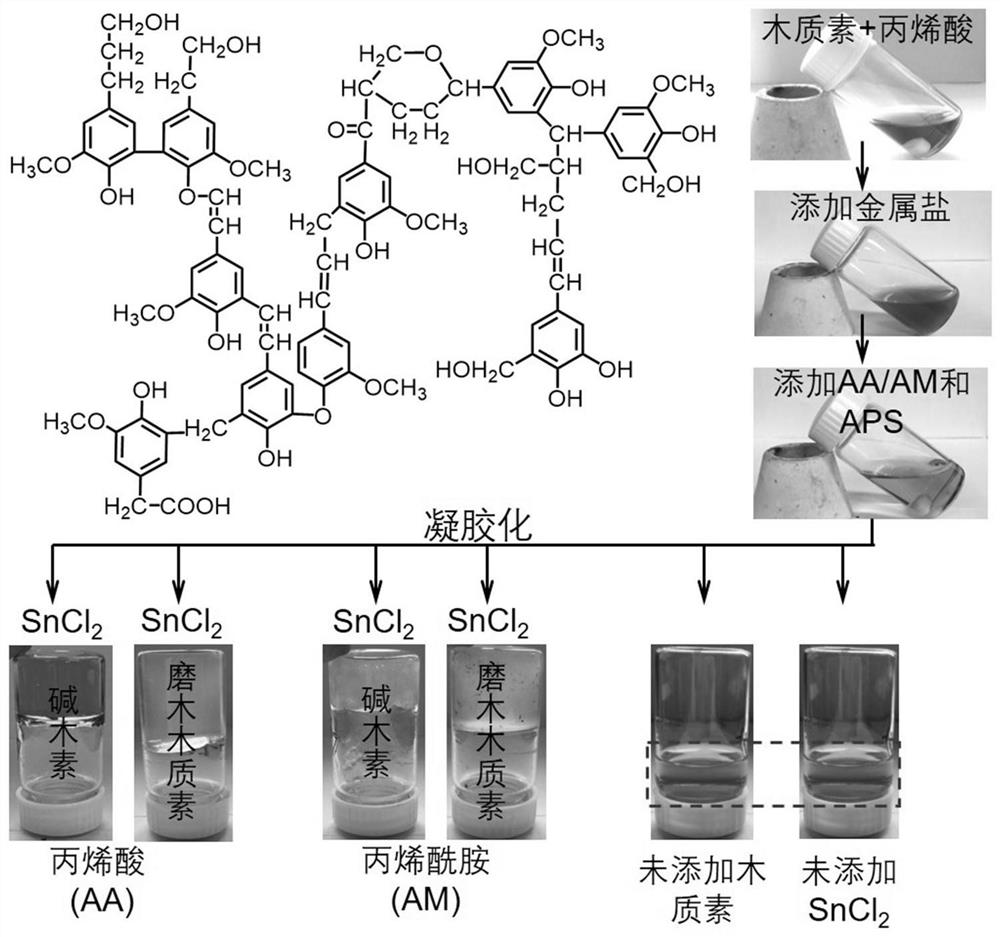

[0033] This example was carried out as follows.

[0034] (1) Take 50g of fir powder, 48g of NaOH and 600mL of deionized water into a 1L autoclave, and react at 120°C for 2h. Filter the resulting mixture to get the supernatant, then adjust the liquid to pH<2 with concentrated hydrochloric acid, let stand, centrifuge, and wash with deionized water until neutral, freeze-dry the sample at -50°C for 48 hours to obtain the base Lignin.

[0035] (2) Add 0.005g of alkali lignin, 0.06g of stannous chloride, and 3.2g of acrylamide into deionized water and mix thoroughly, then drop 0.02g of ammonium persulfate into the mixture, and keep stirring until polymerization forms a gel .

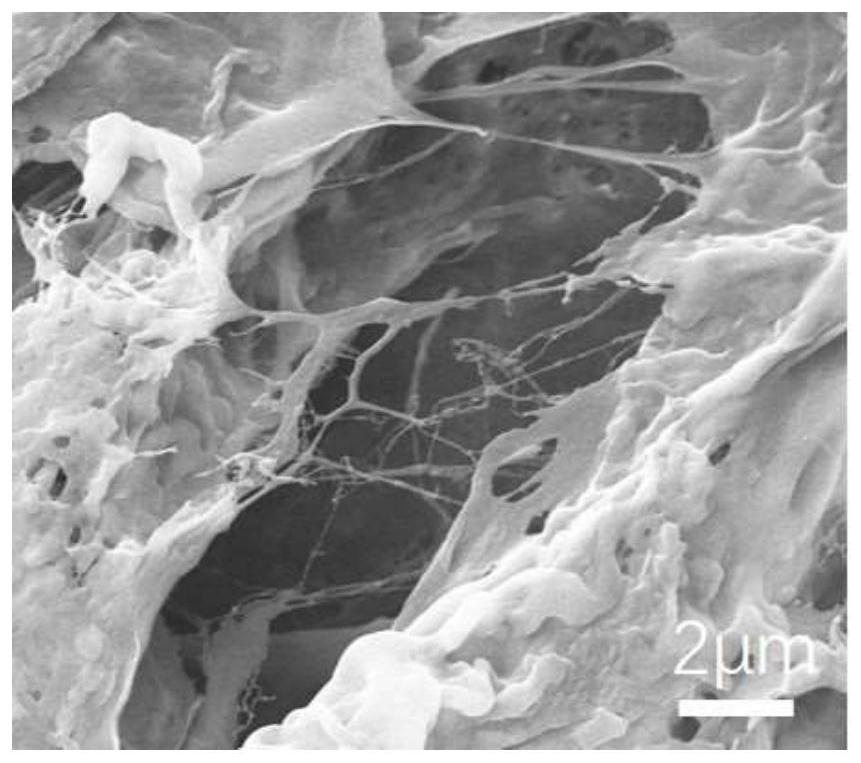

[0036] in, figure 2 A picture showing the as-prepared lignin@Sn hydrogel, the thickness of the hydrogel in this state is about 2 mm. Depend on figure 2 It can be seen that the hydrogel has good transparency and can be stretched. image 3 Scanning electron microscopy (SEM) images of the as-prepared lign...

Embodiment 2

[0040] This example was carried out as follows.

[0041] (1) Obtain alkali lignin according to step (1) of Example 1.

[0042] (2) The operation of step (2) is carried out with reference to the corresponding steps in Example 1, except that the content of alkali lignin in step (2) is 0.010 g.

[0043] Under these conditions, the formation time of the hydrogel obtained is about 8s; the tensile strength is about 20kPa, and the deformation can reach 1600%; the transparency is 90%; the conductivity is 41S m -1 .

Embodiment 3

[0045] This example was carried out as follows.

[0046] (1) Obtain alkali lignin according to step (1) of Example 1.

[0047] (2) The operation of step (2) is carried out with reference to the corresponding steps in the embodiment one, and the difference is that in the step (2), the tin protochloride content is 0.12g.

[0048] Under these conditions, the formation time of the hydrogel obtained is about 5s; the tensile strength is about 16kPa, and the deformation can reach 1100%; the transparency is 85%; the conductivity is 46S m -1 .

[0049] Based on this, this embodiment also treats different Sn 2+ The influence of the concentration on the gel formation time and gel performance was studied, that is, the contents of stannous chloride were 0.2wt%, 0.4wt%, 0.6wt% and 0.8wt%. Figure 4 shows that the formation time of lignin@Sn hydrogels varies with Sn 2+ change in concentration. It can be seen from the figure that with the Sn in the system 2+ The formation time of the hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com