A simple preparation method of environment-friendly structural color emulsion

An environmentally friendly and structurally colored technology, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve problems such as human and environmental hazards and pollution, and avoid cumbersome and complicated processes and preparation steps Convenience, single color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

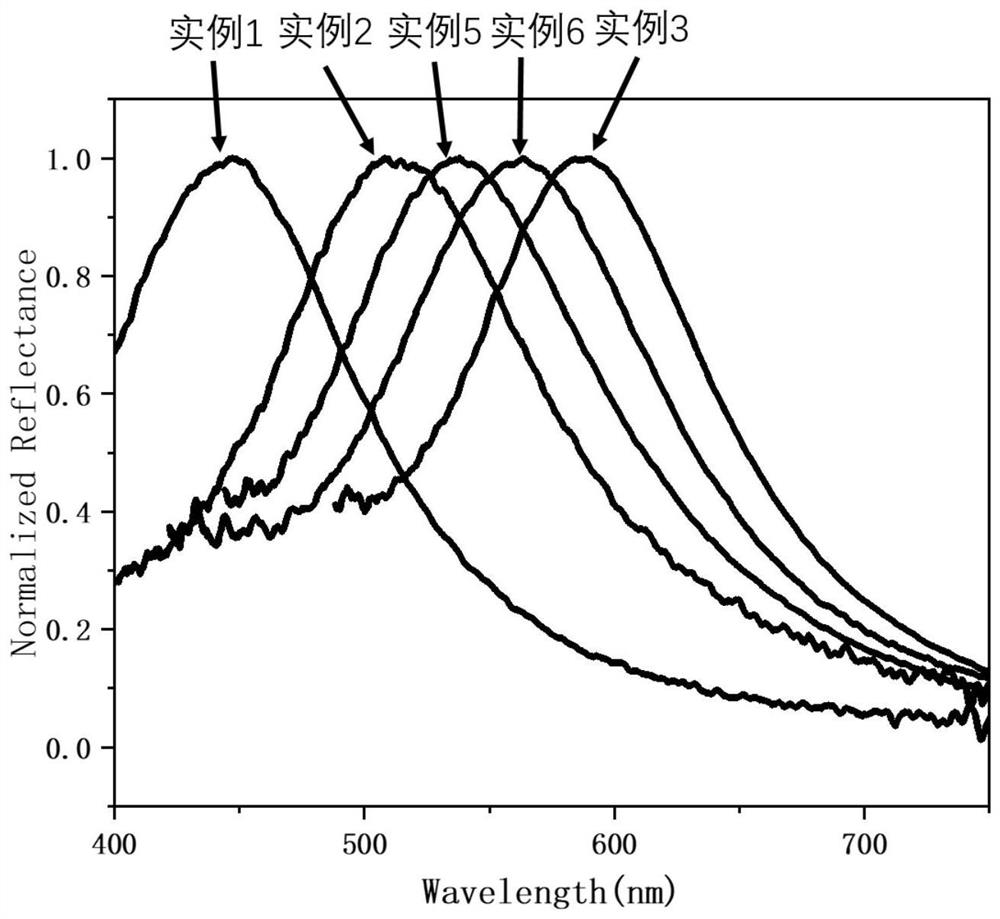

Embodiment 1

[0038] In this example, the environment-friendly structural color emulsion drops, and the specific preparation steps are as follows:

[0039] (1) Polymerization of polylactic acid (PLA) and polyethylene oxide (PEO) by the method of ROMP completely obtains an amphiphilic block polymer brush, wherein the volume fraction of the hydrophilic part of polyethylene oxide (PEO) is 20%.

[0040] (2) Dissolving the amphiphilic block polymer brush synthesized in step (1) in toluene, adding polycaprolactone (PCL) with a mass fraction of 20% of the amphiphilic polymer to prepare a concentration of 20 mg / mL The solution was added to the deionized aqueous solution containing polyvinyl alcohol (PVA) with a mass fraction of 2%, and the amphiphilic emulsion droplets were formed by shaking them. Under the condition of RH), the time for the organic solvent toluene to be completely volatilized is 50h, and blue structural color emulsion droplets are obtained, and the reflection wavelength is at 445...

Embodiment 2

[0042] In this example, the environment-friendly structural color emulsion drops, and the specific preparation steps are as follows:

[0043] (1) Polymerization of polylactic acid (PLA) and polyethylene oxide (PEO) by the method of ROMP completely obtains an amphiphilic block polymer brush, wherein the volume fraction of the hydrophilic part of polyethylene oxide (PEO) is 50%.

[0044] (2) Dissolving the amphiphilic block polymer brush synthesized in step (1) in toluene, adding polycaprolactone (PCL) with a mass fraction of 20% of the amphiphilic polymer to prepare a concentration of 20 mg / mL The solution was added to the deionized aqueous solution containing 2% polyvinyl alcohol (PVA), and the amphiphilic emulsion droplets were formed by shaking them. Under the condition of RH), the time for the organic solvent toluene to be completely volatilized is 50h, and a green structural color emulsion droplet is obtained, and its reflection wavelength is 528nm. The amphiphilic block...

Embodiment 3

[0046] In this example, the environment-friendly structural color emulsion drops, and the specific preparation steps are as follows:

[0047] (1) Polymerization of polylactic acid (PLA) and polyethylene oxide (PEO) by the method of ROMP completely obtains an amphiphilic block polymer brush, wherein the volume fraction of the hydrophilic part of polyethylene oxide (PEO) is 90%.

[0048] (2) Dissolving the amphiphilic block polymer brush synthesized in step (1) in toluene, adding polycaprolactone (PCL) with a mass fraction of 20% of the amphiphilic polymer to prepare a concentration of 20 mg / mL The solution was added to the deionized aqueous solution containing 2% polyvinyl alcohol (PVA), and the amphiphilic emulsion droplets were formed by shaking them. Under the condition of RH), the time for the organic solvent toluene to be completely volatilized is 50h, and the red structural color emulsion droplets are obtained, and the reflection wavelength is at 604nm. The amphiphilic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com