Glass edge grinding machine

A kind of edge grinding machine and glass technology, which is applied in the direction of grinding frame, machine tool suitable for grinding the edge of workpiece, and parts of grinding machine tool, etc. It can solve the problems of inability to adapt to flat glass grinding, lack of sufficient support, stress concentration, etc. , to achieve the effect of complete functions, high processing precision and ensuring mechanical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

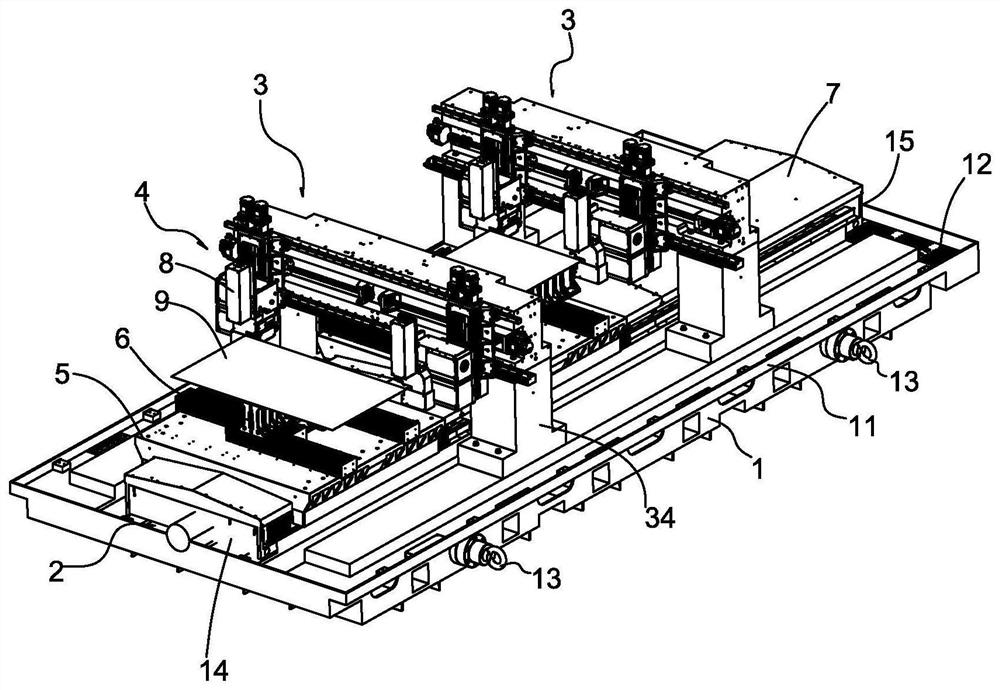

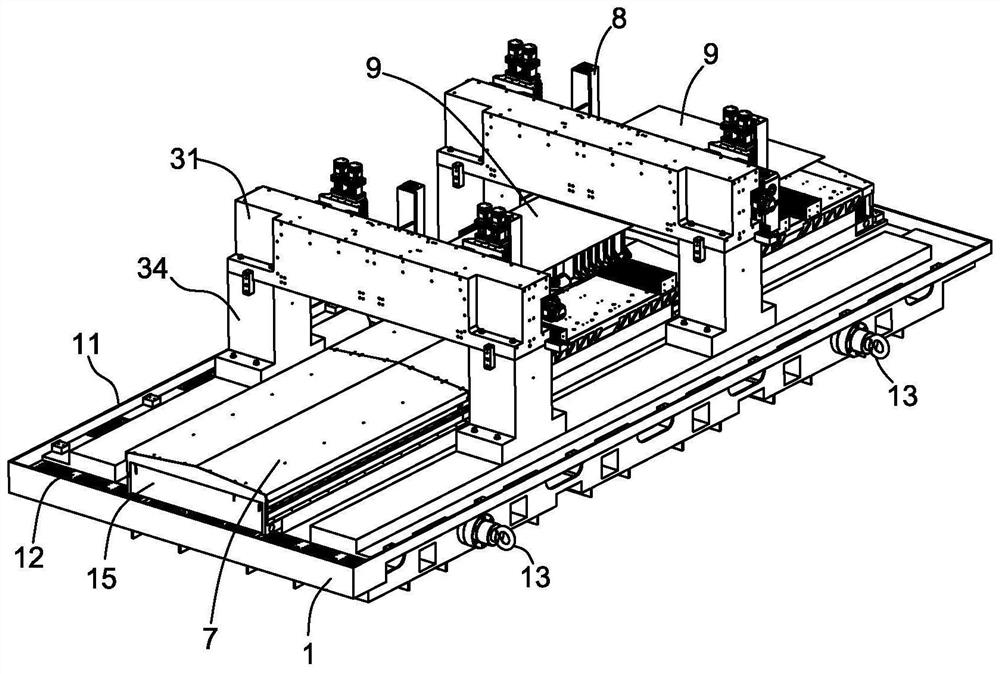

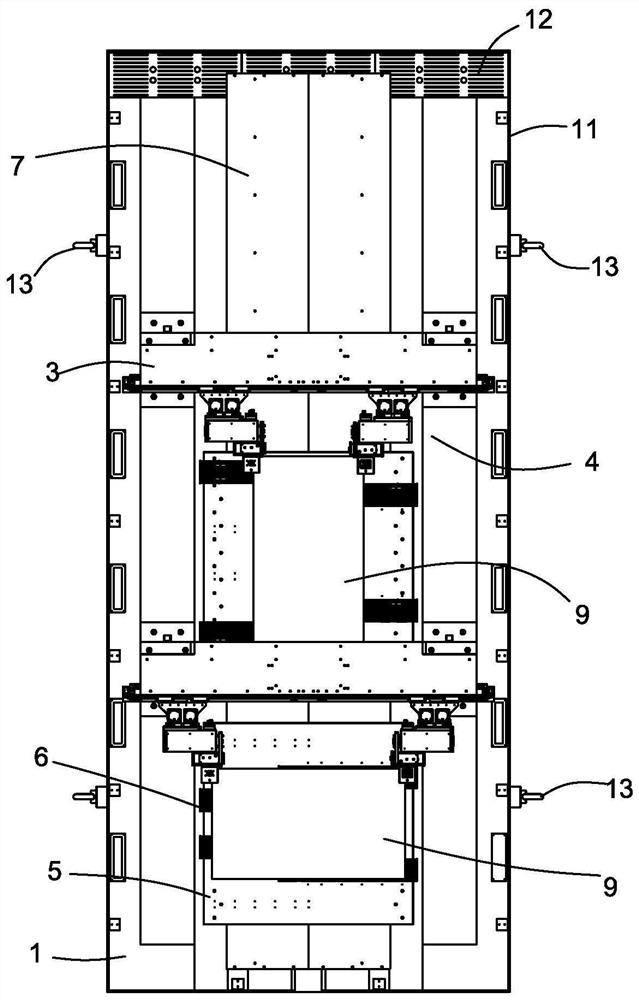

[0052] See Figure 1 to Figure 12 As shown, the present invention is a glass edging machine, which includes: machine base 1, longitudinal driving module 2, horizontal driving module 3, edging module 4, carrying module 5, carrying module 6, cover plate 7 and laser detector 8.

[0053] combine Figure 1 to Figure 4 As shown, the longitudinal driving module 2 is arranged on the base 1 along the longitudinal direction, and is used to drive the carrying module 5 to run along the longitudinal direction. The horizontal drive module 3 is erected above the longitudinal drive module 2, and is used to drive the edging module 4 to run in the transverse direction. The carrying module 6 is installed on the carrying module 5, and moves along the longitudinal direction with the carrying module 5 to the position of the edging module 4 through the longitudinal dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com