Precision machining drilling machine for producing hardware fittings

A technology of precision machining and accessories, applied in metal processing equipment, metal processing mechanical parts, maintenance and safety accessories, etc., can solve the problems of time-consuming and laborious, affecting processing accuracy, dust drift, etc., to reduce environmental pollution, ensure processing accuracy, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

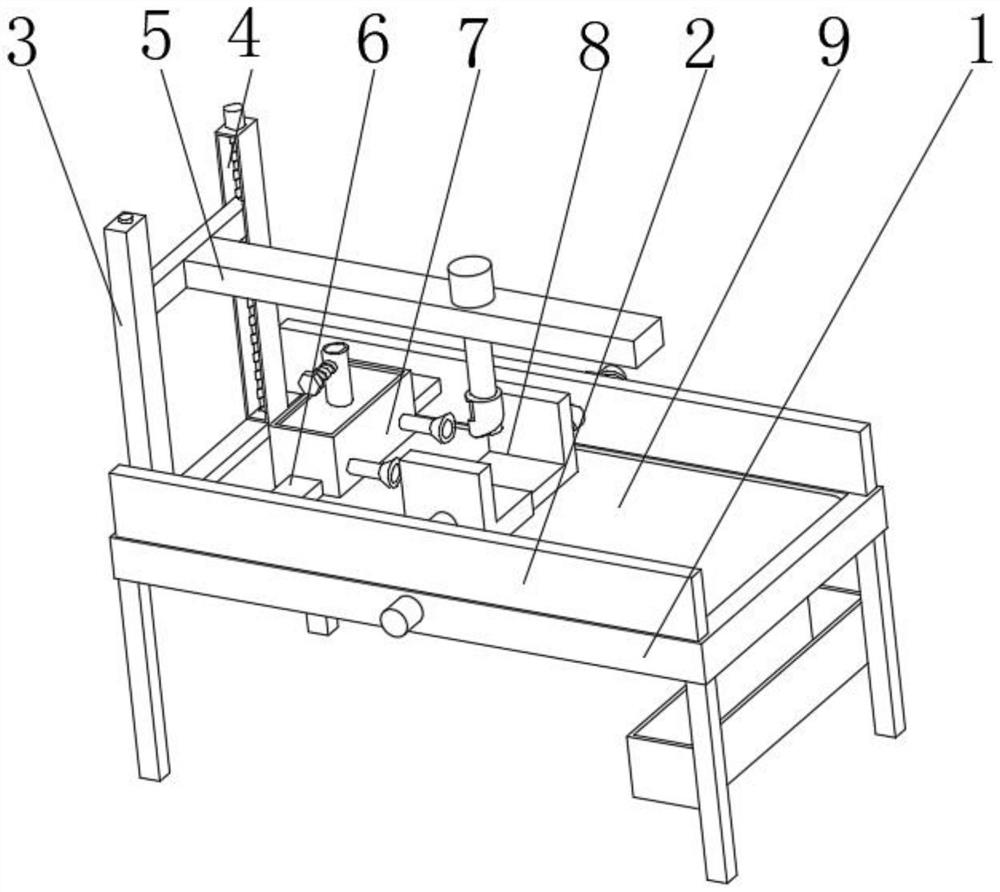

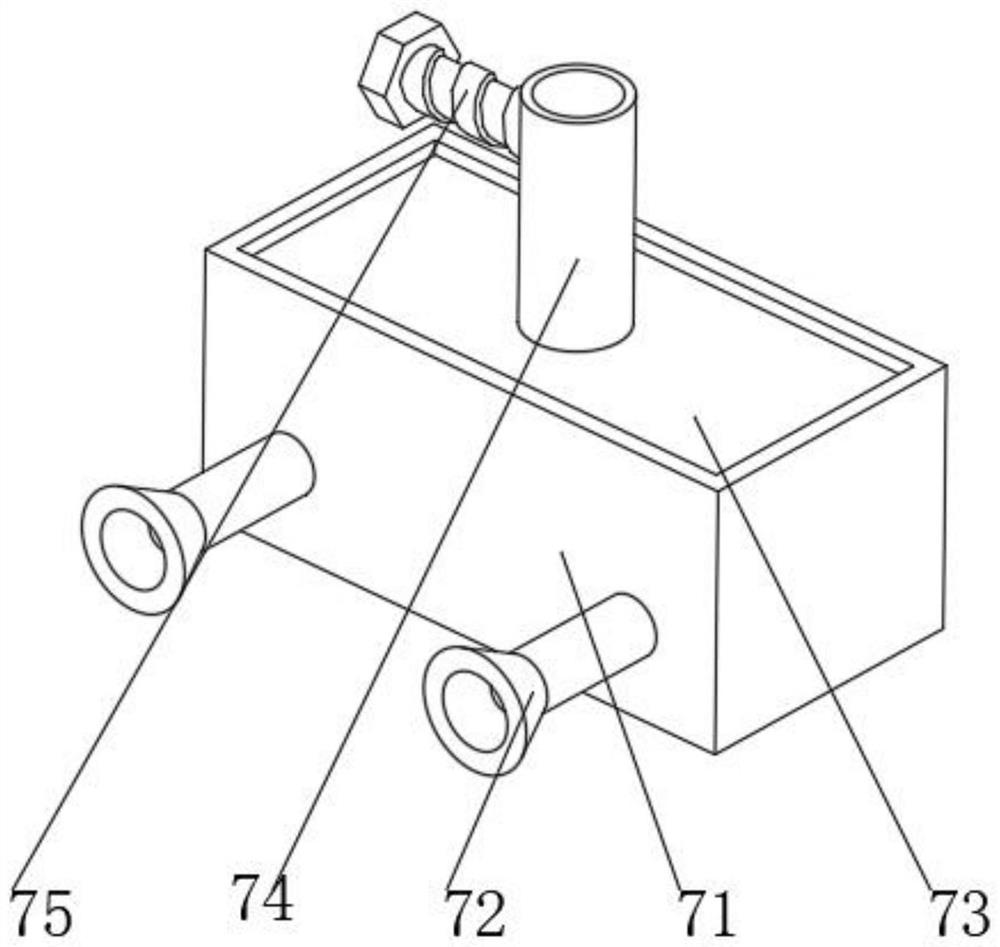

[0022] see Figure 1-5 , the present invention provides a technical solution: a precision machining drilling machine for producing hardware accessories, including a processing table 1, a limit plate 2 is fixedly installed on the upper front part and the upper end rear part of the processing table 1, and the processing table 1 A fixed plate 3 is fixedly installed on the front and rear sides of the upper left part of the upper end, and a chute 4 is provided on the opposite surface of the two fixed plates 3, and the groove walls of the two chute 4 are jointly provided with a sliding processing device 5, two A fixed block 6 is fixedly installed on the left side of the opposite surface of the limiting plate 2, a spraying device 7 is arranged on the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com