A pig manure biogas residue adsorbent and method for rapidly removing doxycycline in water

A pig manure biogas residue and adsorbent technology, applied in the field of environmental governance, can solve the problems of long adsorption time, limited doxycycline adsorption capacity, and low adsorption efficiency, and achieve the effects of low preparation cost, simple operation, and industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of the swine manure biogas residue adsorbent (pig manure biogas residue biochar) that quickly removes doxycycline in the water body, comprising the following steps:

[0022] Mix pig manure residue and potassium permanganate aqueous solution, and ultrasonically treat it to obtain biomass-KMnO 4 The mixture was dried to obtain the dried biomass-KMnO 4 mixture;

[0023] The dried biomass-KMnO 4 The mixture is fired to obtain the pig manure and biogas residue adsorbent loaded with potassium permanganate.

[0024] The present invention mixes pig manure biogas residue and potassium permanganate aqueous solution, and ultrasonically treats it to obtain biomass-KMnO 4 The mixture was dried to obtain the dried biomass-KMnO 4 mixture. The invention utilizes pig manure biogas residues, does not waste waste resources, does not cause secondary pollution to the environment, fully utilizes resources, and is energy-saving and envi...

Embodiment 1

[0032] (1) After drying pig manure and biogas residues to constant weight, crush them with a small pulverizer for 2 to 3 times and pass through a 60-mesh screen, add them according to the solid-liquid ratio of 1:5 until the concentration of the substance is 0.1mol / L Potassium permanganate aqueous solution, and ultrasonic 2h (KH5200DE type numerical control ultrasonic cleaner) under the condition of 25 ℃, 100kHz, obtain biomass-KMnO 4 After the mixture is dried at 60°C;

[0033] (2) The biomass-KMnO dried in step (1) 4 The mixture is fired in a tube furnace at a firing temperature of 500°C, then washed and filtered with deionized water for 3 times, filtered, and dried at 60°C until the moisture content is basically 0 to obtain biogas residue loaded with potassium permanganate Biochar material (ie the swine manure and biogas residue adsorbent of the present invention).

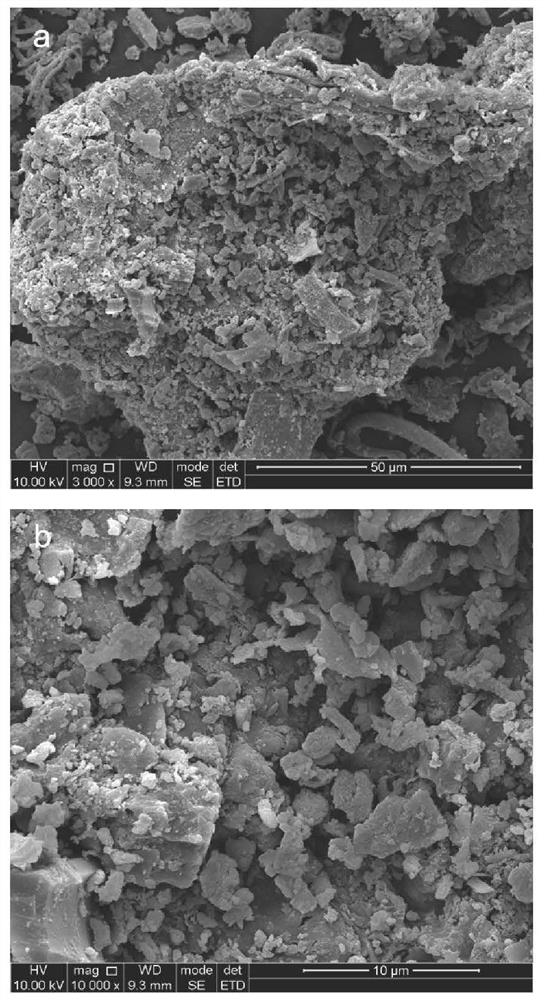

[0034] The scanning electron microscope image of potassium permanganate modified pig manure biochar figure...

Embodiment 2

[0045] The invention discloses a preparation method of a pig manure and biogas residue adsorbent (pig manure and biogas residue biochar) for rapidly removing doxycycline in water bodies. The steps are the same as the adsorption and removal of doxycycline in the water body in Example 1, except that the initial concentration of doxycycline in the water body in Example 2 is 100 mg / L.

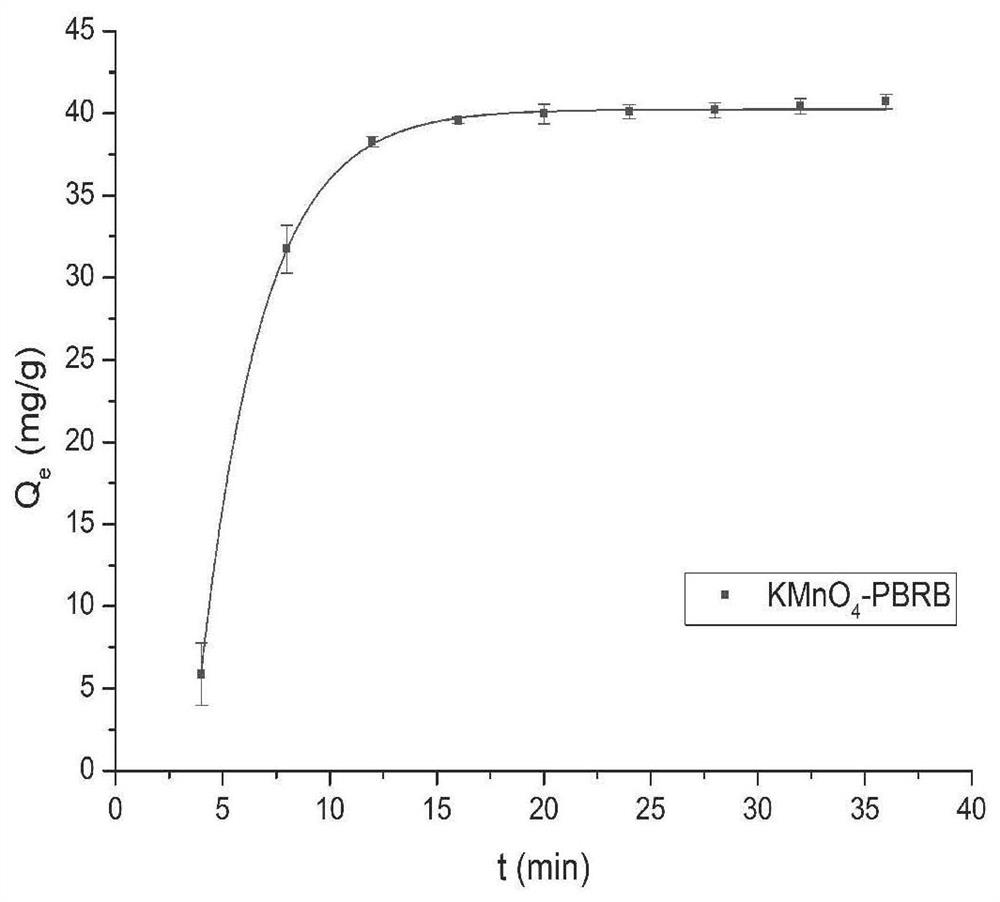

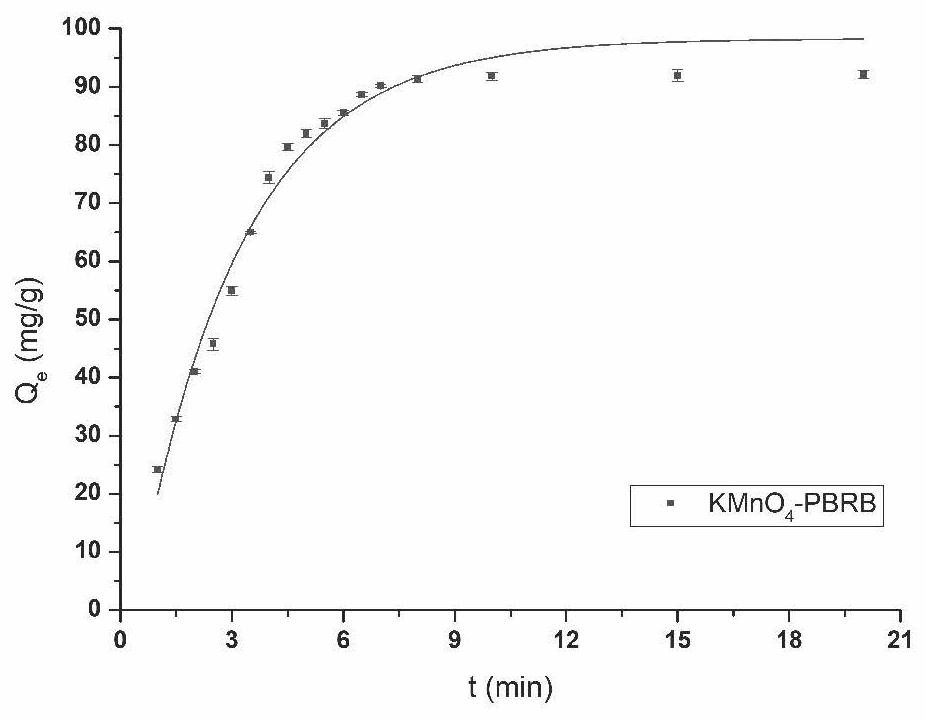

[0046] Take 250 mL of doxycycline solution with a concentration of 100 mg / L, add 250 mg of the swine manure and biogas residue adsorbent prepared in Example 1, place it in a magnetically stirred water bath at 25°C for constant temperature oscillation, and the oscillation time is 7 minutes. After the reaction, the solution settles , using a 0.45 μm microporous membrane for filtration. Measure the concentration of doxycycline in the solution after the reaction with an ultraviolet spectrophotometer, and the calculated adsorption results are shown in image 3 . The results showed that with the increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com