a cr 3 Al/zr multilayer film and its preparation method

A multi-layer thin film and oxide film technology, which is applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of lack of control process of interface structure, etc., and achieve less defects, faster deposition rate, better adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

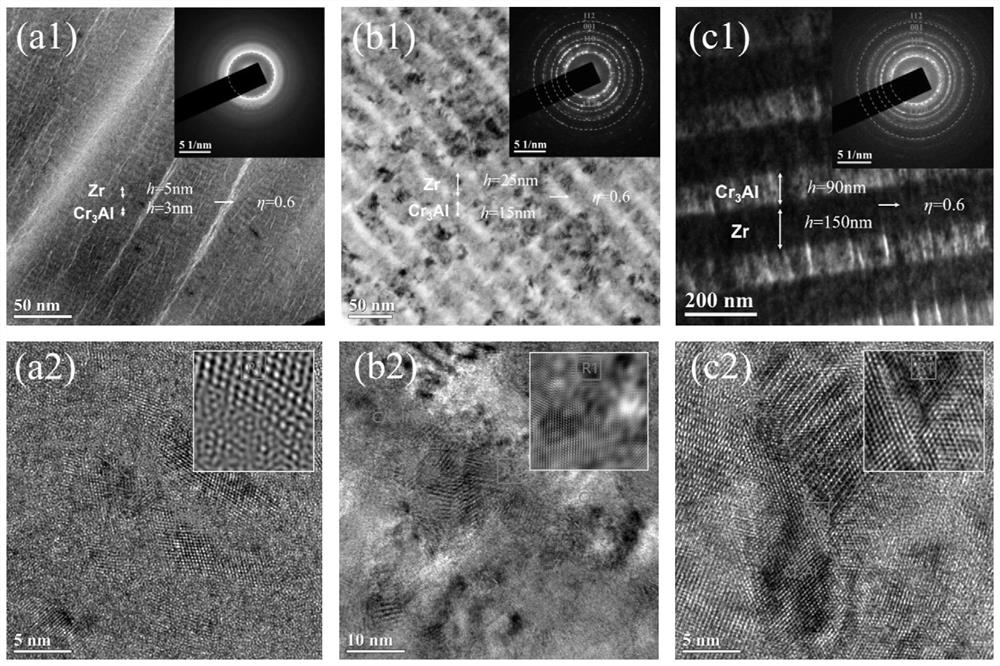

Examples

preparation example Construction

[0037] Above Cr 3 The preparation method of Al / Zr multilayer thin film, comprises the following steps:

[0038] Step 1), the polished silicon substrate is ultrasonically cleaned in acetone and absolute ethanol in sequence, and then dried, and the dried silicon substrate is eroded by hydrofluoric acid aqueous solution to remove the oxide film on its surface;

[0039] Specifically, the silicon substrate is polished on one side, then soaked in acetone and absolute ethanol successively, ultrasonically cleaned for at least 15 minutes, and then dried. Afterwards, the treated silicon substrate is soaked in a hydrofluoric acid aqueous solution with a concentration of 45 wt.%, corroded for about 1 min, and then dried.

[0040] Fix the silicon substrate on the substrate with conductive glue, and send it into the coating chamber, and pump the vacuum to 1.0×10 -4 Below Pa.

[0041] Step 2), in the high vacuum environment, at first utilize Ar + Ion etching to further remove impurities ...

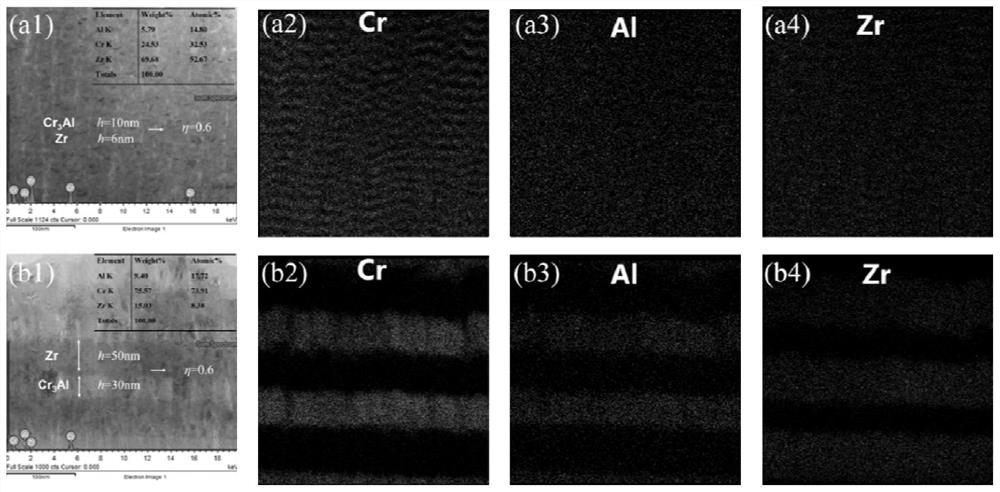

Embodiment 1

[0046] Present embodiment 1 is implemented under the following implementation conditions and technical requirements:

[0047] First, acetone and absolute ethanol are used to remove impurities on the surface of the target and the substrate in sequence, and then the impurities and oxides on the surface of the target and the substrate are removed by hydrofluoric acid aqueous solution.

[0048] Then, use conductive glue to fix the substrate on the substrate, and mechanically and automatically send it into the magnetron sputtering vacuum coating chamber, and pump it until the vacuum degree of the back is 1.6×10 -4 Pa starts etching, the etching power is 200W, and the etching time is 5min.

[0049] Secondly, after the etching is completed, the formal sputtering starts: firstly, the argon gas is injected for 30s, and the pre-sputtering is performed for 10s, and then the Cr 3 Al / Zr multilayer film;

[0050] Among them, Cr 3 The power of Al target (purity 99.99wt.%) and Zr target (p...

Embodiment 2

[0054] This embodiment 2 is implemented under the following implementation conditions and technical requirements:

[0055] First, acetone and absolute ethanol are used to remove impurities on the surface of the target and the substrate in sequence, and then the impurities and oxides on the surface of the target and the substrate are removed by hydrofluoric acid aqueous solution.

[0056] Then, use conductive glue to fix the substrate on the substrate, and mechanically and automatically send it into the magnetron sputtering vacuum coating chamber, and pump it until the vacuum degree of the back is 2.4×10 -4 Pa starts etching, the etching power is 200W, and the etching time is 5min.

[0057] Secondly, after the etching is completed, the formal sputtering starts: firstly, the argon gas is injected for 30s, and the pre-sputtering is performed for 10s, and then the Cr 3 Al / Zr multilayer films, where Cr 3 The power of the Al target (purity 99.99wt.%) and the Zr target (purity 99.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com