Carton die-cutting machine

A die-cutting machine and carton technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of increasing storage space, affecting cutting work, and paper residues, and achieving the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

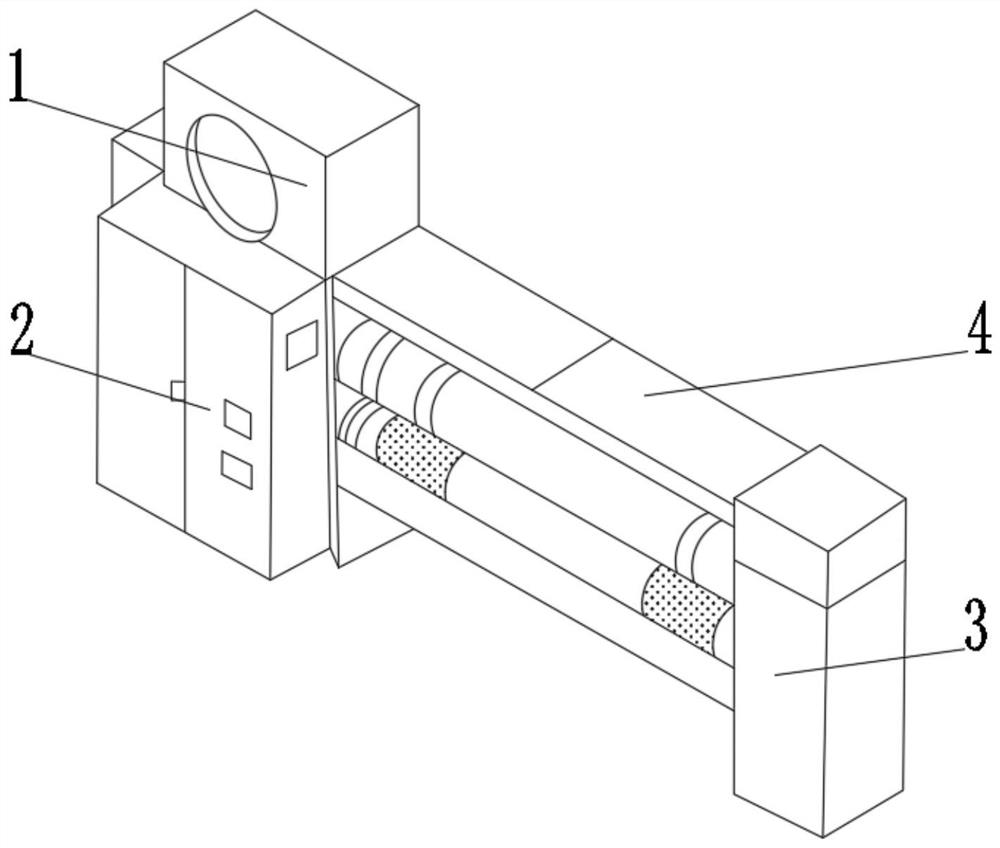

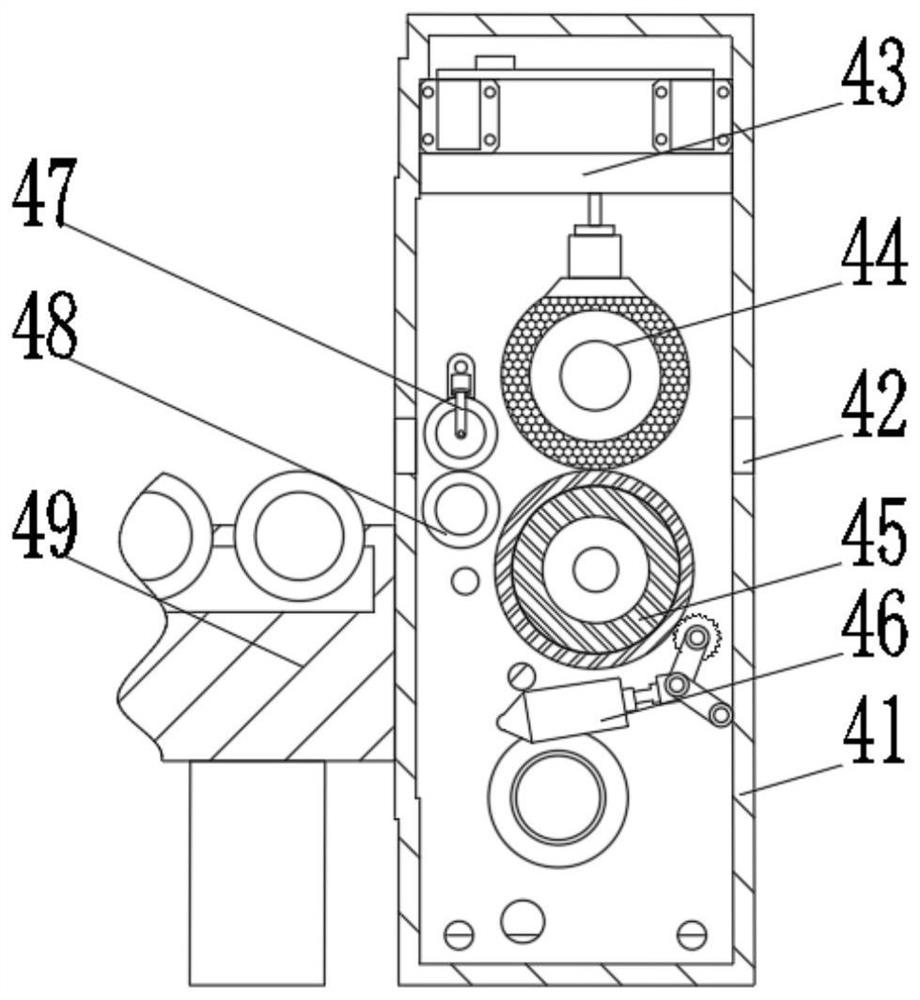

[0034] see Figure 1-2 , the present invention provides a technical solution: a carton die-cutting machine, including a die-cutting control box 1, a door panel 2 is arranged on one side of the die-cutting control box 1, and a fixed frame 3 is fixedly connected to one side of the die-cutting control box 1 , the inside of the fixed frame 3 is provided with a cutting mechanism 4, the cutting mechanism 4 includes a cutting and fixing shell 41, both sides of the cutting and fixing shell 41 are provided with feed ports 42, and the inner wall sides of the cutting and fixing shell 41 are fixedly connected with Fixed plate 43, one side of the fixed plate 43 is provided with a cutting device 44, the side of the cutting device 44 away from the fixed plate 43 is provided with a first motorized roller 45, and the side of the first motorized roller 45 away from the cutting device 44 is provided with a cleaning mechanism 46, the cutting and fixing casing 41 is provided with a pressure roller...

Embodiment 2

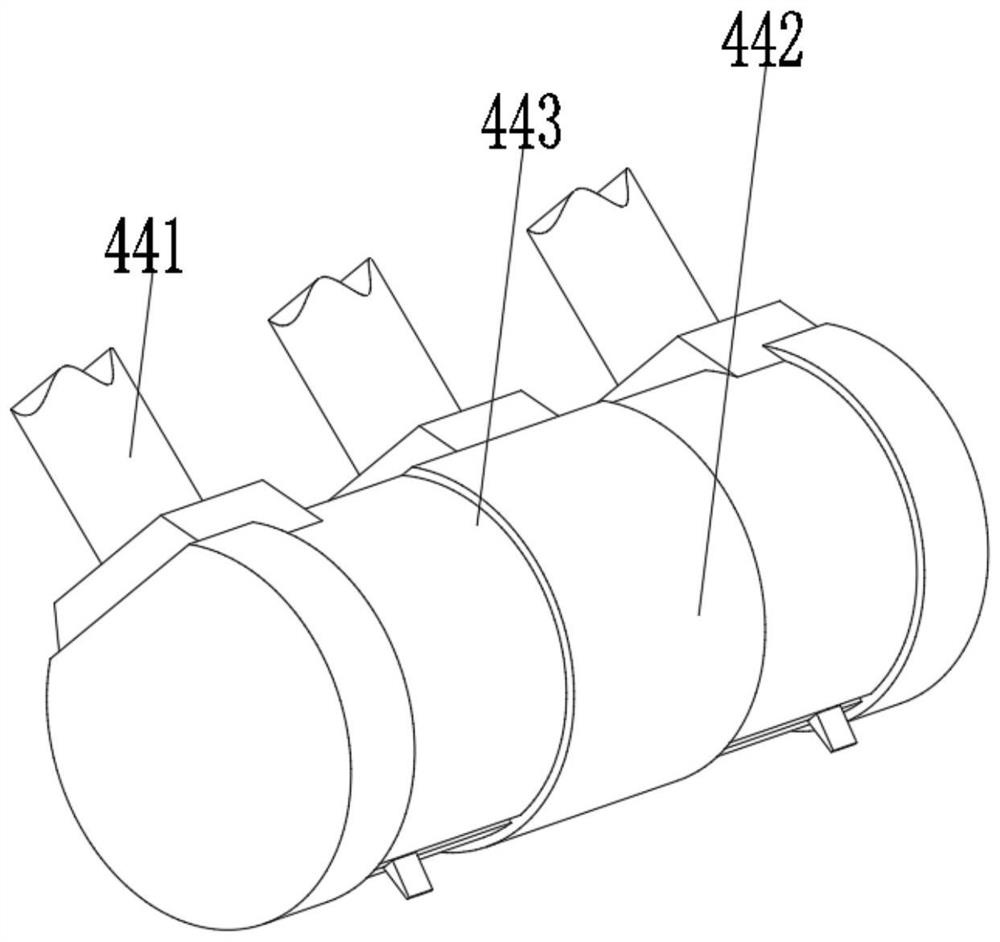

[0037] see Figure 2-5, the present invention provides a technical solution on the basis of Embodiment 1: a carton die-cutting machine, the cutting device 44 includes a telescopic rod 441, and one end of the telescopic rod 441 is fixedly connected with a connecting and fixing device 442, and the inner wall of the connecting and fixing device 442 The side is fixedly connected with a cutting rod 443, and the cutting rod 443 includes a cutting shell a1, and one side of the cutting shell a1 is provided with a mounting groove a2, and one side of the inner wall of the mounting groove a2 is fixedly connected with a blade cleaning device a3, and the cutting shell a1 The sides are fixedly connected with the guide rod a4 and the sliding connection housing a5, the inner wall side of the sliding connection housing a5 is fixedly connected with the electromagnetic block a6, and the side of the electromagnetic block a6 away from the sliding connection housing a5 is slidingly connected with th...

Embodiment 3

[0040] see Figure 4-6 , the present invention provides a technical solution on the basis of Embodiment 2: a carton die-cutting machine, the cutting knife seat a8 includes a knife seat shell a81, and one side of the knife seat shell a81 is provided with a connecting groove a82, and the connecting groove One side of a82 is provided with a limiting block a83, and the end of the limiting block a83 away from the connecting groove a82 is fixedly connected with a cutting blade a84, and the upper side of the cutting blade a84 close to the limiting block a83 is fixedly connected with a spring a85, and the spring a85 is away from One side of the cutting blade a84 is fixedly connected with the knife base housing a81, one end of the cutting blade a84 is rotationally connected with the knife base housing a81 through a rotating shaft, and the side of the knife base housing a81 close to the cutting blade a84 is fixedly connected with The arc-shaped limit rod a86, the side of the cutting bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com