Preparation method of copper oxide catalyst for catalyzing persulfate to degrade pollutants in water

A technology of persulfate and copper oxide, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Low-level problems, achieve the effects of less dosage, improved removal efficiency, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: the preparation method of the copper oxide catalyst used to catalyze persulfate to degrade pollutants in water in this embodiment is carried out according to the following steps:

[0027] 1. Adding Cu(NO 3 ) 2 ·6H 2 O and organic carbon sources were dissolved in ultrapure water, and stirred evenly at room temperature to obtain a mixed solution; wherein Cu(NO 3 ) 2 ·6H 2 The molar ratio of O and organic carbon source is (1-100): (1-100);

[0028] 2. Place the mixed solution in an oven and dry to obtain a precipitate;

[0029] 3. Calcining the precipitate at high temperature, grinding and sieving the precipitate after cooling to obtain a copper oxide catalyst; wherein the temperature for high-temperature calcination is 300° C. to 1000° C., and the calcination time is 1-4 hours.

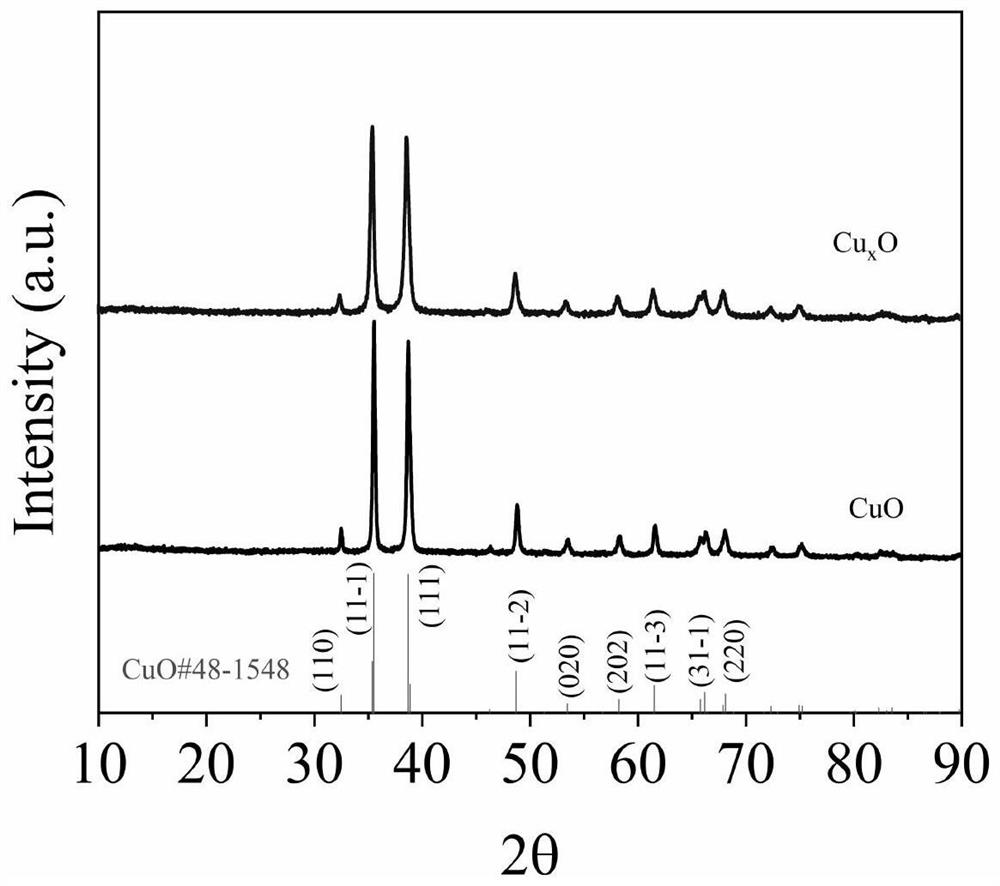

[0030] In this embodiment, part of the divalent copper atoms are reduced to monovalent copper atoms during the preparation process, and the structure of the copper ...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: Cu(NO 3 ) 2 ·6H 2 The molar ratio of O to organic carbon source was 8:1. Others are the same as the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the organic carbon source is citric acid or glucose. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com