High-toughness corrosion-resistant light alloy aluminum material for ultra-high-voltage line, and preparation process thereof

A lightweight alloy, corrosion-resistant technology, applied in the direction of metal/alloy conductors, circuits, conductive materials, etc., can solve the problems of affecting the reliability of UHV lines, shortening the service life of UHV lines, and insufficient corrosion resistance. The effect of reducing the damage of the line, improving the hardness and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

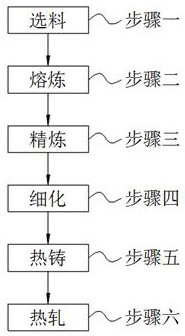

Method used

Image

Examples

Embodiment 1

[0030] A high-strength, toughness, and corrosion-resistant light alloy aluminum material for UHV lines, the formula includes: aluminum ingot, crystalline silicon, copper ingot, aluminum-strontium master alloy, aluminum-magnesium master alloy, aluminum-manganese master alloy and aluminum-titanium-boron master alloy, each The parts by weight of the components are: 30-40 parts of aluminum ingot, 32-38 parts of crystalline silicon, 5-9 parts of copper ingot, 4-8 parts of aluminum strontium intermediate alloy, 13-25 parts of aluminum-magnesium intermediate Alloy, 7-12 parts of aluminum-manganese master alloy and 5-10 parts of aluminum-titanium-boron master alloy, the purity of the aluminum element in the aluminum ingot is 99.8%. The purity of silicon element in crystalline silicon is 99.7%, the purity of copper element in copper ingot is 99.5%, the content of strontium element in aluminum-strontium master alloy is 8%, the content of magnesium element in aluminum-magnesium master all...

Embodiment 2

[0039] A high-strength, toughness, and corrosion-resistant light alloy aluminum material for UHV lines, the formula includes: aluminum ingot, crystalline silicon, copper ingot, aluminum-strontium master alloy, aluminum-magnesium master alloy, aluminum-manganese master alloy and aluminum-titanium-boron master alloy, each The parts by weight of the components are: 30-40 parts of aluminum ingot, 32-38 parts of crystalline silicon, 5-9 parts of copper ingot, 4-8 parts of aluminum strontium intermediate alloy, 13-25 parts of aluminum-magnesium intermediate Alloy, 7-12 parts of aluminum-manganese master alloy and 5-10 parts of aluminum-titanium-boron master alloy, the purity of the aluminum element in the aluminum ingot is 99.8%. The purity of silicon element in crystalline silicon is 99.7%, the purity of copper element in copper ingot is 99.5%, the content of strontium element in aluminum-strontium master alloy is 8%, the content of magnesium element in aluminum-magnesium master all...

Embodiment 3

[0048] A high-strength, toughness, and corrosion-resistant light alloy aluminum material for UHV lines, the formula includes: aluminum ingot, crystalline silicon, copper ingot, aluminum-strontium master alloy, aluminum-magnesium master alloy, aluminum-manganese master alloy and aluminum-titanium-boron master alloy, each The parts by weight of the components are: 30-40 parts of aluminum ingot, 32-38 parts of crystalline silicon, 5-9 parts of copper ingot, 4-8 parts of aluminum strontium intermediate alloy, 13-25 parts of aluminum-magnesium intermediate Alloy, 7-12 parts of aluminum-manganese master alloy and 5-10 parts of aluminum-titanium-boron master alloy, the purity of the aluminum element in the aluminum ingot is 99.8%. The purity of silicon element in crystalline silicon is 99.7%, the purity of copper element in copper ingot is 99.5%, the content of strontium element in aluminum-strontium master alloy is 8%, the content of magnesium element in aluminum-magnesium master all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com