Crease type vibration fan blade

A fan blade and blade technology, which is applied in the field of wrinkled vibrating fan blades, can solve the problems of increasing fan complexity, increasing uncertain factors, increasing processing difficulty, etc., to achieve increased complexity, improved service life, and improved heat dissipation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

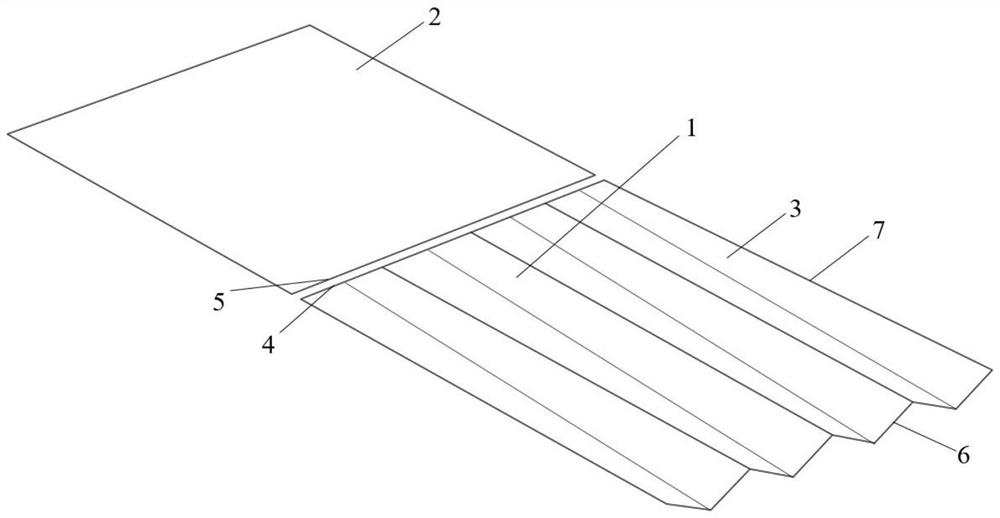

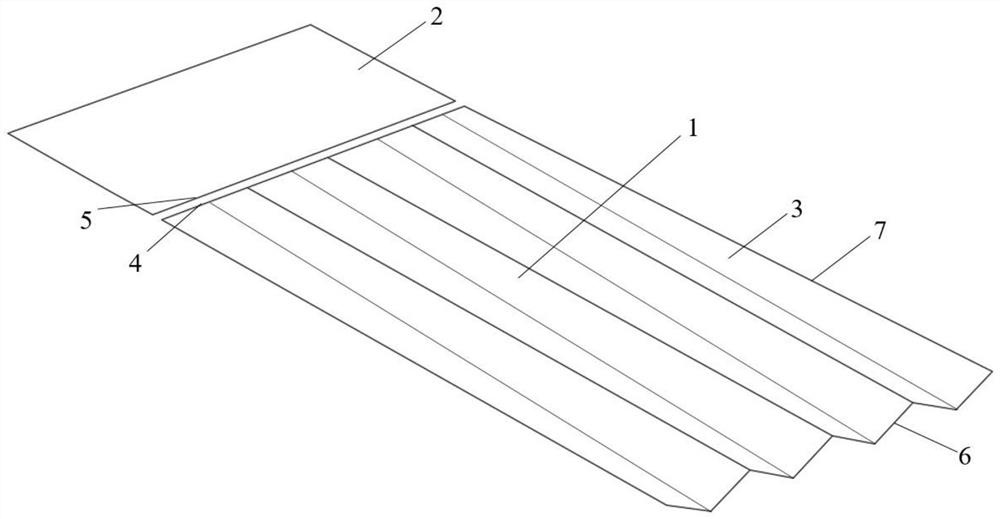

Embodiment 1

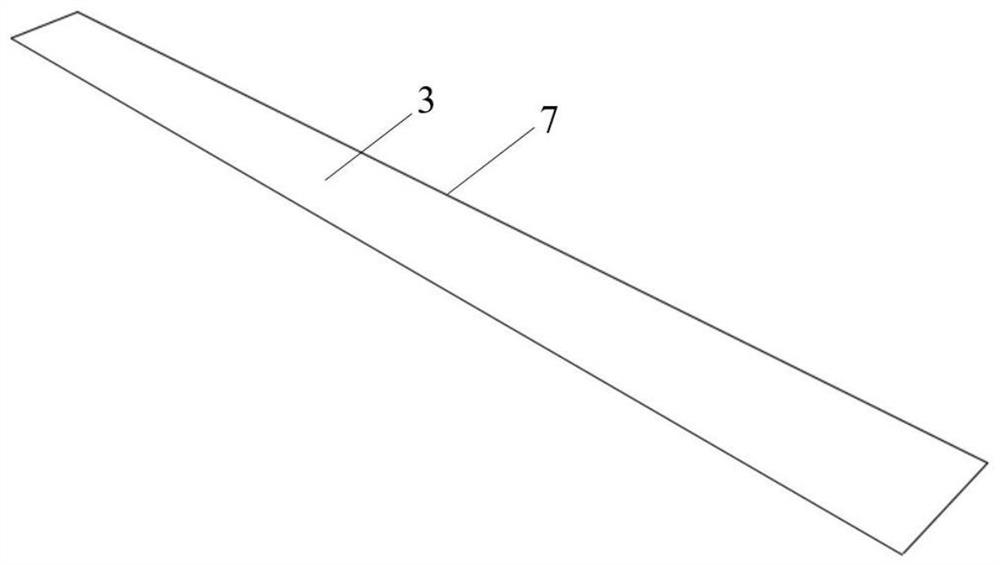

[0027] In this embodiment, the corrugated part 1 is composed of four identical basic units, and the side length of the corrugated part 1 is equal to the side length of the straight part 2; The sides 7 are of equal length.

[0028] The blades of the invention and the traditional rectangular blades (that is, four sides are linear, straight blades) of the wrinkle part 1 composed of 4 basic units are respectively installed in the vibrating fan, and the wind speed at the center position of the top of the blade is monitored when the blade is working ( Such as Figure 7 Shown), compare the wind effect. Experiments show that the vibrating fan installed with the blades of the present invention can obtain a greater air outlet effect. Compared with the vibrating fan with traditional rectangular blades, the maximum wind speed can be increased by 0.58m / s, and the average wind speed in one vibration cycle can be increased by 0.43m / s. s. Through specific example tests, the blade of the pr...

Embodiment 2

[0030] In this embodiment, the corrugated part 1 is composed of four identical basic units, and the side length of the corrugated part 1 is greater than that of the straight part 2; The lengths of sides 7 are equal.

Embodiment 3

[0032] In this embodiment, the creased part 1 is composed of four different basic units, the maximum side length of the creased part 1 is equal to the side length of the straight part 2, and the remaining side lengths are smaller than the sides of the straight part 2 Length: the top side 6 of the crease part is a triangular sawtooth, and the side lengths of the four basic units are all different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com