Preparation and application of superfine powder concrete

An ultra-fine powder and concrete technology, applied in the field of high-performance composite materials for construction, can solve the problems of large-scale reuse of fly ash without major breakthroughs, concrete pollution, air pollution, etc., and achieve huge technical economic benefits and social Benefit, save energy, prolong the service life of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

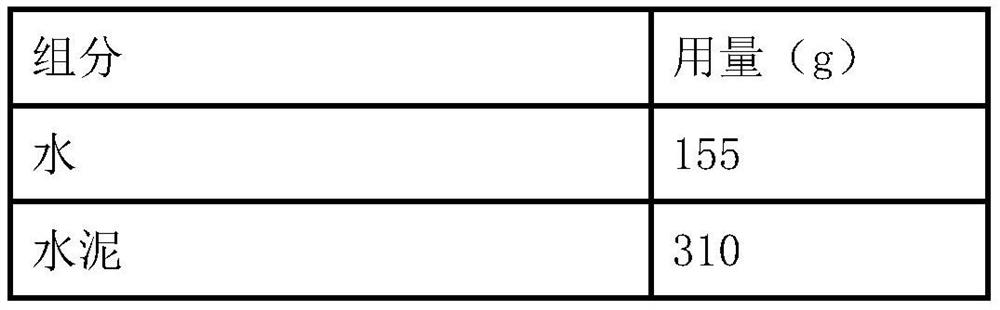

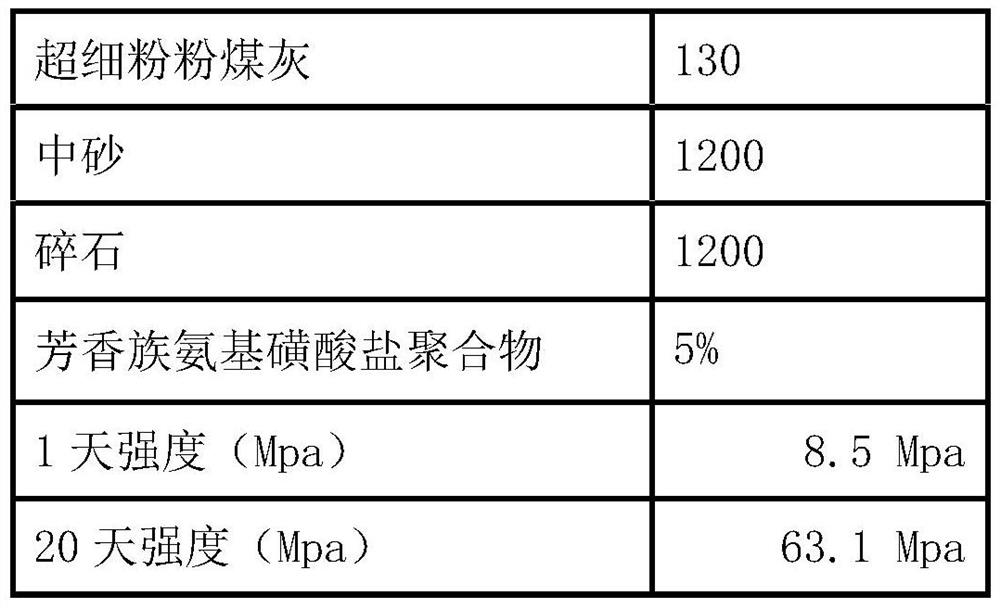

[0031] formula:

[0032]

[0033] As mentioned above is the superfine powder concrete formula, its early and late strength has been significantly enhanced, and the strength can exceed 6Mpa in one day. The 20-day strength exceeds 60Mpa, while the 1-day strength of ordinary concrete generally does not exceed 4Mpa, and its 28-day late strength is generally lower than 50Mpa.

[0034] That is, by adding a certain proportion of ultra-fine fly ash into the concrete formula, the early and late strength of concrete can be effectively improved, and the setting time of concrete can be significantly shortened.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com