Fermented bean curd-based porous carbon material, and preparation method and application thereof

A technology of porous carbon material and fermented bean curd, which is applied in the field of fermented bean curd-based porous carbon material and its preparation, which can solve the problems of affecting product yield, insufficient pore formation, and low specific surface area, so as to achieve easy industrialization and increase surface wettability , the effect of high electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of preparation method of the fermented bean curd base porous carbon material that a carbon precursor and basic inorganic substance mass ratio are 1.0:2.0, comprises the following steps:

[0044] Step 1) Preparation of carbon precursor, wash the fermented bean curd and dry it in a blast drying oven at 80°C, then grind the fermented bean curd into powder, and then pre-carbonize the obtained powder in a tube furnace under the protection of nitrogen atmosphere, The temperature is 500°C, the pre-carbonization time is 2h, and the heating rate is 5°C / min to obtain a carbon precursor;

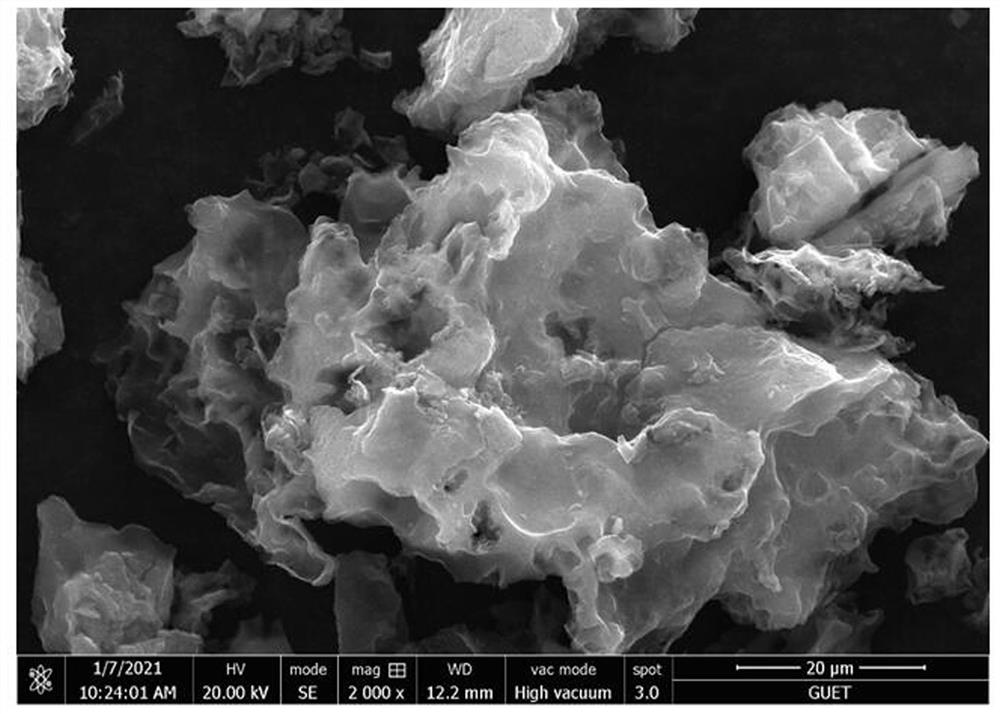

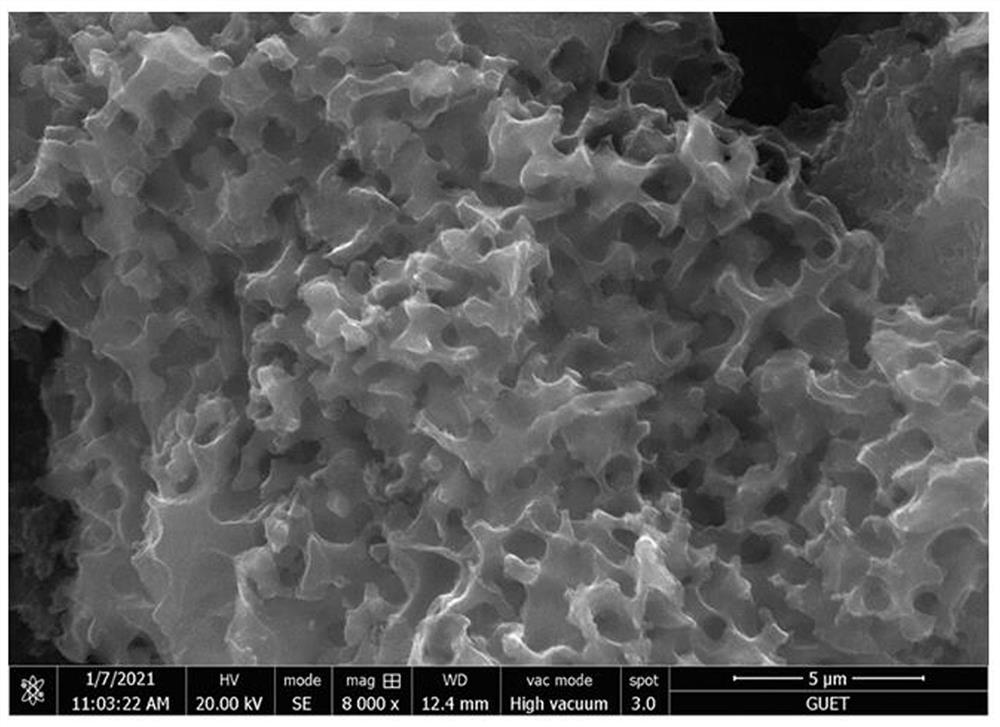

[0045] In order to prove that pre-carbonization can preserve the pore structure of fermented bean curd, the carbon precursor obtained in step 1 was detected by scanning electron microscopy (SEM), and the results are as follows figure 1 As shown, the carbon precursor has a pore structure.

[0046] Step 2) Preparation of fermented bean curd-based porous carbon material, according to a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com