Semi-dry SCR denitration system and method for cement kiln

A semi-dry, cement kiln technology, applied in the field of air pollution control, can solve the problems of large denitrification investment, high operation cost, easy blockage and poisoning, etc., and achieves the effects of high reaction efficiency, reduced management difficulty, and reduced pharmaceutical costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

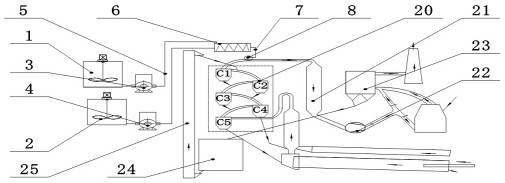

[0039] refer to figure 1 , a 4000t / d cement plant, the kiln tail flue gas is discharged from the C1 preheater, flows through the waste heat boiler (or humidification tower), high temperature fan, (raw meal mill), bag filter, kiln tail fan, The chimney is discharged into the atmosphere, among which, the discharge temperature at the C1 preheater is 300-350°C, and the SNCR denitrification system is installed at the calciner, and the kiln tail flue gas is normally NO X The emission is stable at 200-320mg / m 3 , to meet the national special area emission standards. As the local cement industry implements ultra-low emission requirements, after the company introduces this embodiment, its NO X The emission is stable at 10-30mg / Nm 3 , which can reduce 395 tons of NO emissions per year X . The specific process of this embodiment scheme is as follows: Utilize equipment such as preheater system 20, flue gas pipeline 21, high-temperature fan 22, kiln tail dust collector 23 of existing ...

Embodiment 2

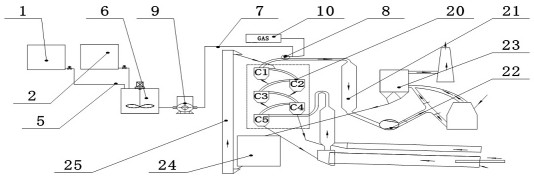

[0041] refer to figure 2 , a 5000t / d cement plant, the kiln tail flue gas is discharged from the C1 preheater, flows through the waste heat boiler, high temperature fan, (raw meal mill), bag filter, kiln tail fan, and chimney, and then is discharged into the atmosphere , among which, the discharge temperature at the C1 preheater is 280-330°C, and the SNCR denitrification system is installed at the calciner. Under normal conditions, the kiln tail flue gas is NO X The emission is stable at 200-250mg / m 3 , to meet the national special area emission standards. As the local cement industry implements ultra-low emission requirements, it is required to achieve a nitrate emission of 50 mg / m in 2022 3 , after the company introduces the scheme of this embodiment, its NO X The emission is stable at 5-35mg / Nm 3 . The specific process of this embodiment scheme is as follows: Utilize equipment such as the preheater system 20 of existing dry-process cement kiln, flue gas pipeline 21, h...

Embodiment 3

[0043] refer to image 3 , a 5000t / d cement plant, the kiln tail flue gas is discharged from the C1 preheater, flows through the waste heat boiler, high temperature fan, (raw meal mill), bag filter, kiln tail fan, and chimney, and then is discharged into the atmosphere , among which, the discharge temperature at the C1 preheater is 250-300°C, and the SNCR denitrification system is installed at the calciner. Normally, the kiln tail flue gas is NO X The emission is stable at 250-350mg / m 3 , after the company introduces the scheme of this embodiment, its NO X The emission is stable at 5-35mg / Nm 3 . The specific process of this embodiment scheme is as follows: use the preheater system 20, exhaust pipe 21, high-temperature fan 22, kiln tail dust collector 23 and other equipment of the existing dry process cement kiln; set the liquid distribution device 11, the electric control device 12. Distributor 13, according to manganese sulfate: iron sulfate: tungsten sulfate: vanadyl sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com