Bacteriostatic and deodorant cat litter composition and preparation method thereof

A technology of composition and cat litter, applied in animal houses, food processing, animal husbandry and other directions, can solve the problems of acute toxicity of pets, high cost of raw materials, strong penetrability, etc., and can inhibit the growth of mold and bacteria. , The effect of reducing odor accumulation and maintaining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

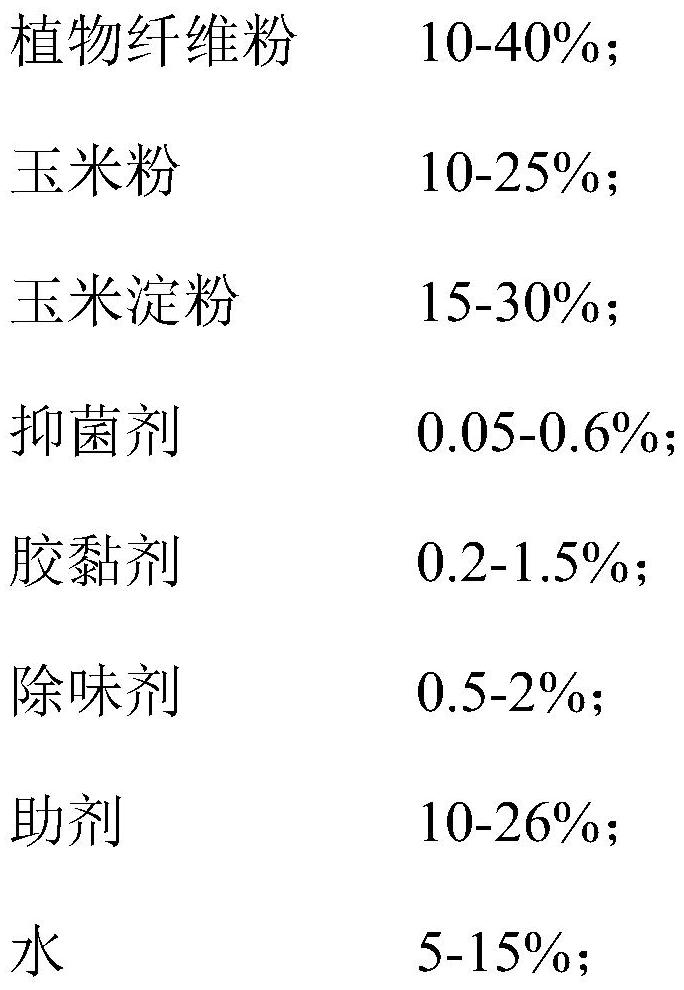

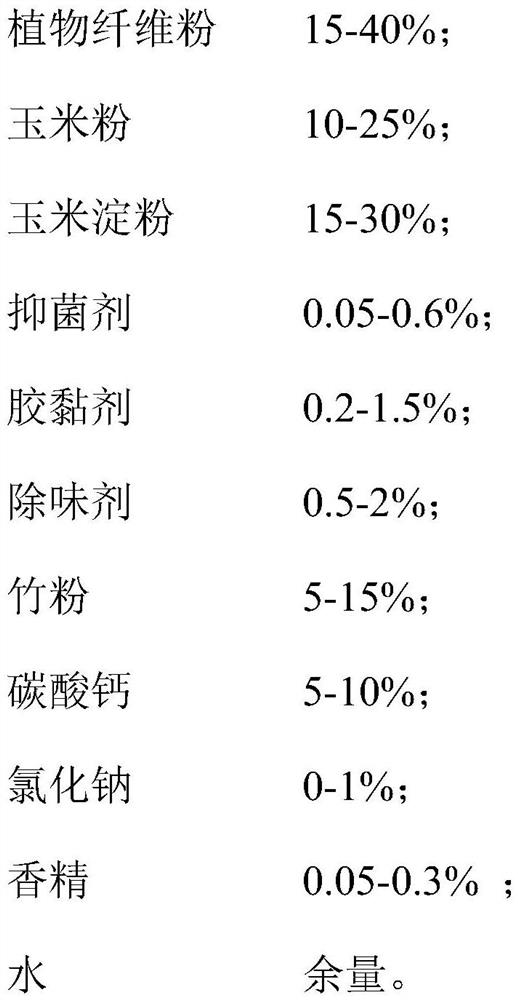

Method used

Image

Examples

preparation example Construction

[0050] A preparation method of antibacterial and deodorizing cat litter composition, comprising the following steps:

[0051] Mix plant fiber powder, corn flour, corn starch, deodorant, adhesive, additives and water, and stir to prepare a mixture;

[0052] Carrying out dry granulation to the mixture, drying to prepare granules;

[0053] Mix the particulate matter and bacteriostatic agent.

[0054] Understandably, before mixing plant fiber powder, corn flour, corn starch, deodorant, adhesive, auxiliary agent and water, it may also include sieving plant fiber powder, corn flour and corn starch to remove large particle impurities A step of.

[0055] The mix can be prepared in the batch pot.

[0056] Specifically, first put plant fiber powder, corn flour, corn starch, deodorant, adhesive and additives into the batching pot, stir for 5 to 8 minutes, then spray water evenly, and continue stirring for 5 to 15 minutes.

[0057] Understandably, the above water may be soft water.

...

Embodiment 1

[0073] Embodiment 1 provides a kind of antibacterial and deodorizing cat litter composition and preparation method thereof, the steps are as follows:

[0074] 1) In terms of mass percentage, weigh 10% of low-protein pea fiber powder, 23% of degermed corn flour, 27% of corn starch, 0.3% of iodopropynyl butyl carbamate, 0.1% of imidazolidinyl urea, and hydroxypropyl urea. Cyclodextrin 2%, sodium polyacrylate 0.2%, CMC-Na 0.2%, guar gum 0.6%, bamboo powder 15%, calcium carbonate 5%, sodium chloride 0.8%, essence 0.25%, soft water balance .

[0075] 2) Pass the low-protein pea fiber powder, degermed corn flour and corn starch through a 10-mesh sieve to remove large particles of impurities, then put them into the batching pot, and then put hydroxypropyl beta cyclodextrin and sodium polyacrylate into the batching pot , CMC-Na, guar gum, bamboo powder, calcium carbonate and sodium chloride, stirred for 6 minutes, then evenly sprayed soft water, and continued to stir for 10 minutes t...

Embodiment 2-5

[0079] Embodiment 2-5 provides a kind of antibacterial and deodorizing cat litter composition and preparation method thereof, and the steps are as follows:

[0080] 1) Weigh the raw materials with reference to the formula shown in Table 1.

[0081] 2) With reference to the method of Example 1, the antibacterial and deodorizing cat litter compositions of Examples 2-5 were prepared.

[0082] Table 1

[0083]

[0084] For example: the preparation method of the antibacterial and deodorizing cat litter composition of embodiment 2 is as follows:

[0085] 1) In terms of mass percentage, weigh 15% of low-protein pea fiber powder, 22% of degermed corn flour, 30% of corn starch, 0.3% of iodopropynyl butyl carbamate, 0.1% of imidazolidinyl urea, and hydroxypropyl urea. Dibeta cyclodextrin 1.5%, sodium polyacrylate 0.4%, bamboo powder 15%, calcium carbonate 5%, sodium chloride 0.5%, essence 0.2%, soft water balance.

[0086] 2) Pass the low-protein pea fiber powder, degermed corn fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com