Polishing slurry composition and method for producing same

A technology of composition and slurry, which is applied to polishing compositions containing abrasives, chemical instruments and methods, and other chemical processes, can solve the problems of scratches on polishing particles, adjust flatness and control, and achieve excellent polishing rate, improve flatness, and prevent dents and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

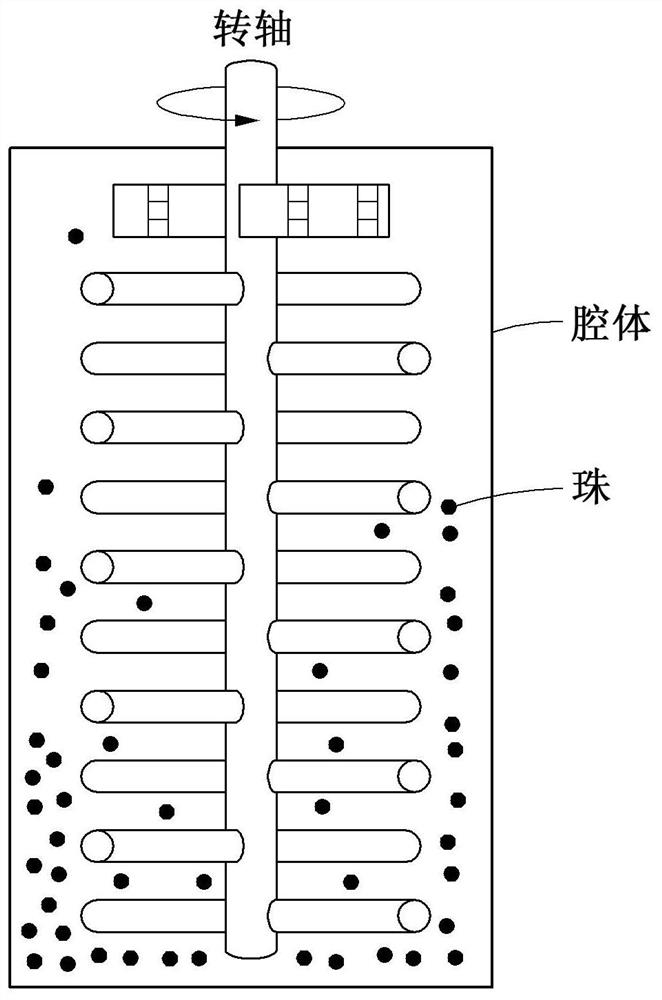

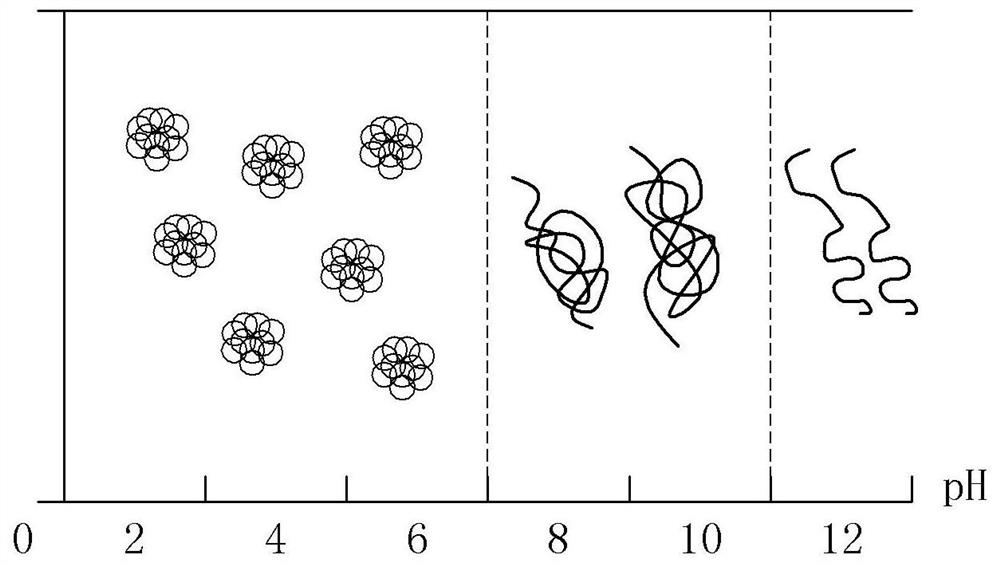

[0093] A method for preparing a polishing slurry composition according to another embodiment of the present invention includes the steps of: dispersing polishing particles such that the surface of the particles has a positive charge, a first dispersant comprising a nonionic linear polymer, and a first dispersant comprising an anion a step of preparing a polishing slurry by mixing a second dispersant of a linear coil polymer; and a step of grinding the polishing slurry using beads.

[0094] And, according to the preparation method of the polishing slurry composition of the present invention, the primary particle size of the polishing particles is controlled by adjusting the grinding energy during the grinding process, based on the reduction of the particle size, preventing dents and scratches from occurring during polishing, reducing the number of processes, Increase productivity.

[0095] According to one aspect, the grinding is performed using beads with a diameter ranging fr...

Embodiment 1

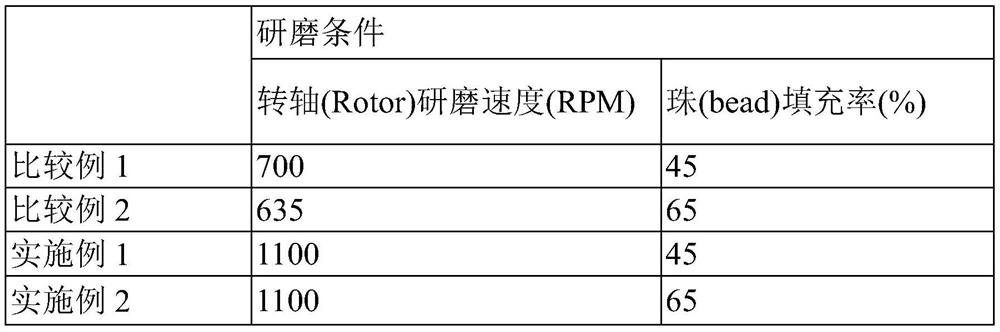

[0119] In Example 1, Example 2, Comparative Example 1 and Comparative Example 2, the silicon pattern wafer was polished under the following polishing conditions.

[0120] [Polishing condition]

[0121] 1. Polishing device: AP-300 (CTS company)

[0122] 2. Pad: K7 (Rohm&Hass)

[0123] 3. Polishing time: 60s

[0124] 4. Platen speed: 93

[0125] 5. Spindle speed: 87

[0126] 6. Flow rate: 250ml / min

[0127] 7. Chip pressure: 3.0psi

[0128] 8. Chips used:

[0129] PE-TEOS LP-Nitride P-doped polymer (P_DopedPoly)

[0130] STI Nitride Pattern (Nitride Pattern) HDP Trench )

[0131] Show respectively in the following table 2 the grinding energy of embodiment 1, embodiment 2, comparative example 1 and comparative example 2, the polishing characteristic (grinding energy=rotating shaft grinding speed (rpm) in the polishing slurry composition after polishing and polishing × bead filling rate (%)). Particle size is the size measured by XRD.

[0132] 【Table 2】

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com