Water cooling and automatic dust removal device for camera

An automatic dust removal and camera technology, applied in the field of machinery, can solve the problems of high working environment temperature of hot rolling production line, easy generation of dust, affecting camera shooting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

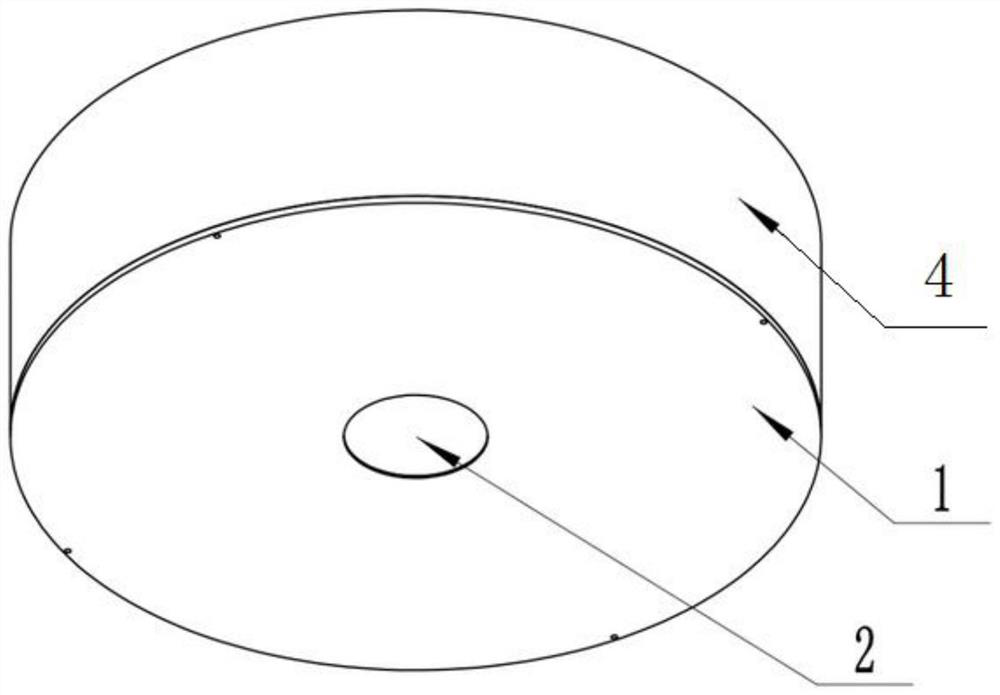

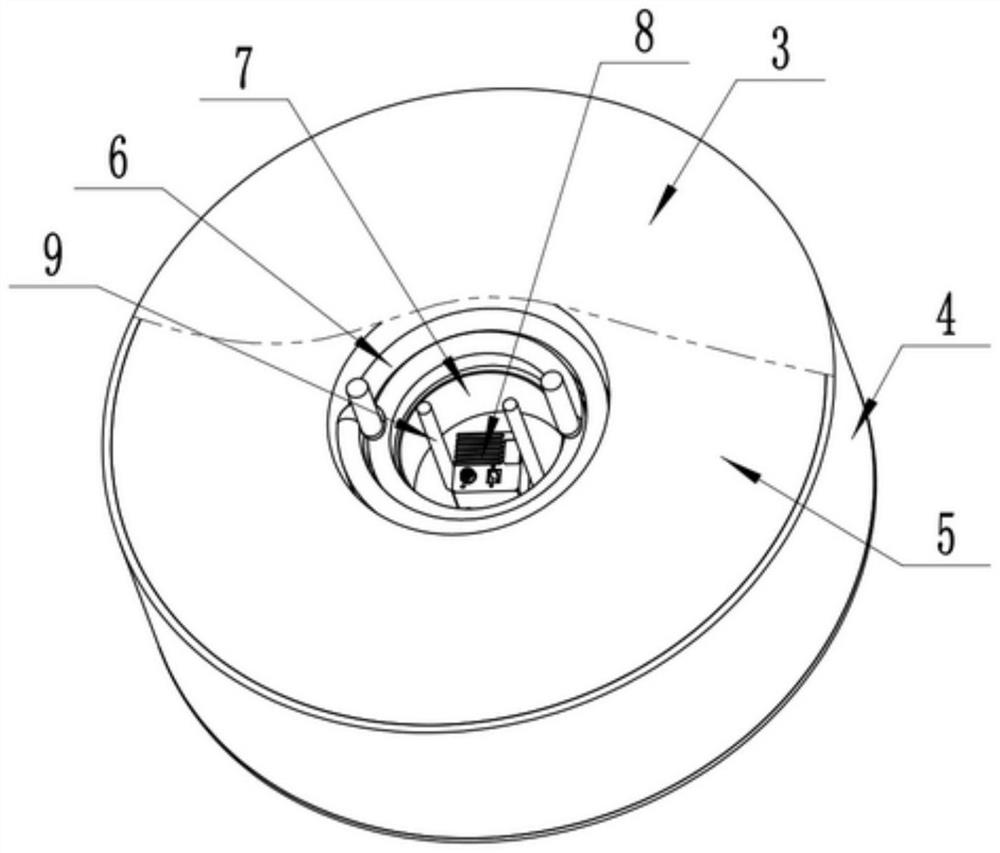

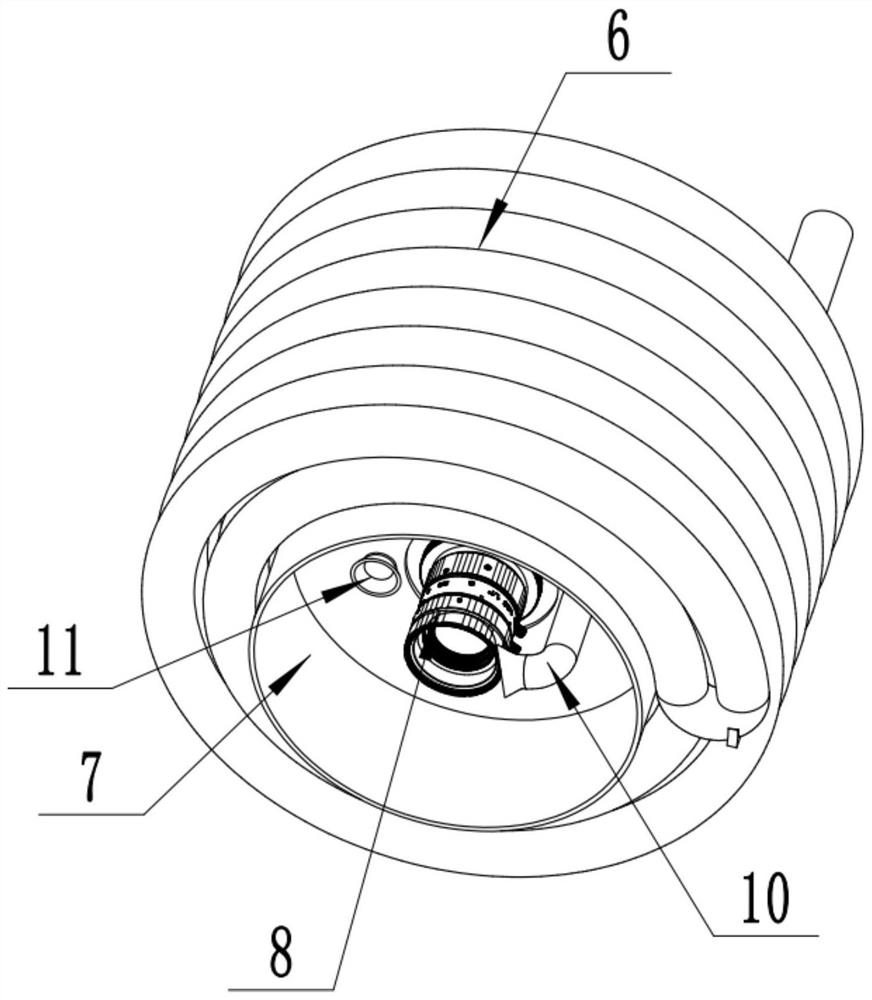

[0018] Such as Figure 1-3 As shown, a camera water-cooling and automatic dust removal device includes an outer cylinder 4, heat insulation cotton 5, a cooling water pipe 6, an inner cylinder 7, a dust removal mechanism 9 and a temperature sensor. The camera 8, the dust removal mechanism 9 and the temperature sensor are arranged in the In the inner cylinder 7, the cooling water pipe 6 is wound around the inner cylinder 7, the heat insulation cotton 5 wraps the cooling water pipe 6, and the outer cylinder 4 covers the heat insulation cotton 5. The inner cylinder 7 is provided with a partition, and the partition divides the inner cylinder 7 into an upper layer and a lower layer; the camera 8 is fixedly arranged on the partition, and the camera lens is placed in the lower layer of the inner cylinder; the temperature sensor Installed on the upper layer of the inner cylinder to monitor the temperature around the camera 8 in real time. The upper end of the outer cylinder 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com