Catalytic combustion treatment device for adsorbed waste gas

A catalytic combustion and treatment device technology, which is applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems that the activated carbon plate cannot be fully and effectively used, and the exhaust gas cannot be fully dispersed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

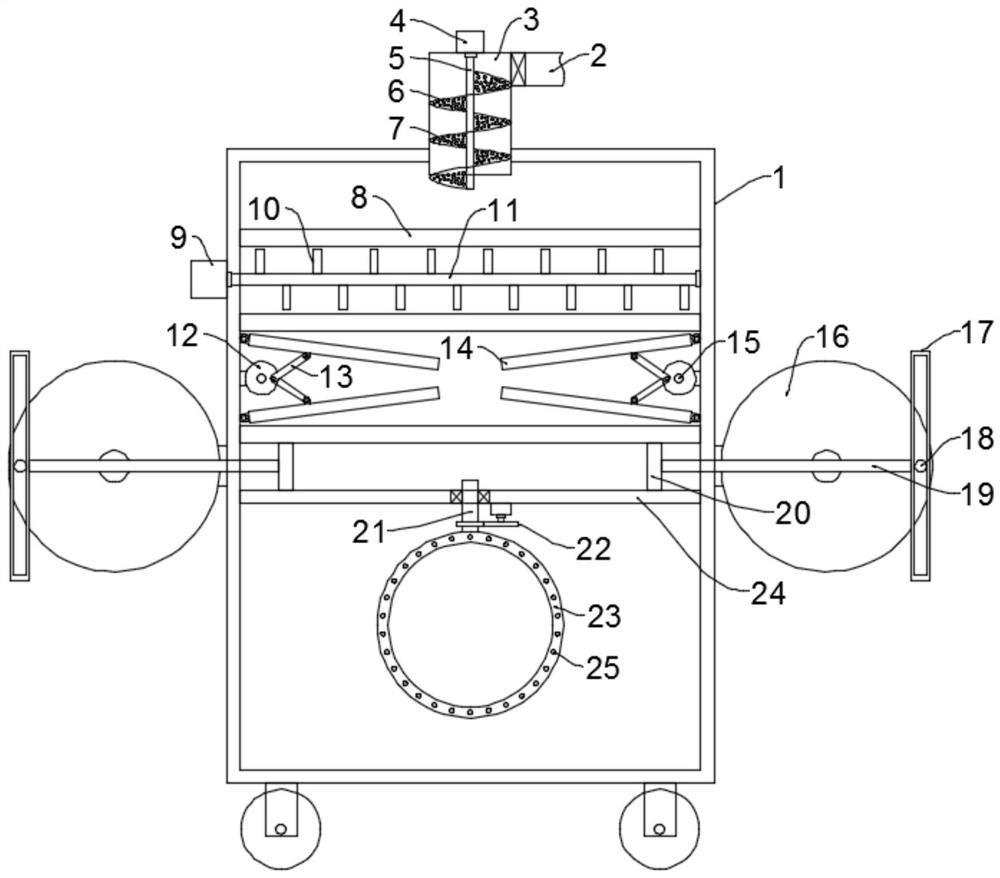

[0024] see figure 1 , In the embodiment of the present invention, a catalytic combustion treatment device for adsorbing exhaust gas includes a box body 1. The bottom of the box body 1 is evenly and symmetrically fixed with rollers to facilitate the movement of the device. A box door is installed on the box body 1. Preferably, it is connected to the box body 1 through hinges and buckles. The box body 1 is divided into an adsorption chamber and a catalytic combustion chamber by a horizontally arranged partition plate 24. The partition plate 24 is provided with a communication pipe 21 for connecting the adsorption chamber and the catalytic combustion chamber. , the adsorption chamber is located above the catalytic combustion chamber, and an air intake unit is installed on the top of the box 1 . In this embodiment, the air intake unit includes a dispersion cylinder 3 , a first motor 4 , a first rotating shaft 5 and auger blades 6 The dispersion cylinder 3 is fixedly installed on t...

Embodiment 2

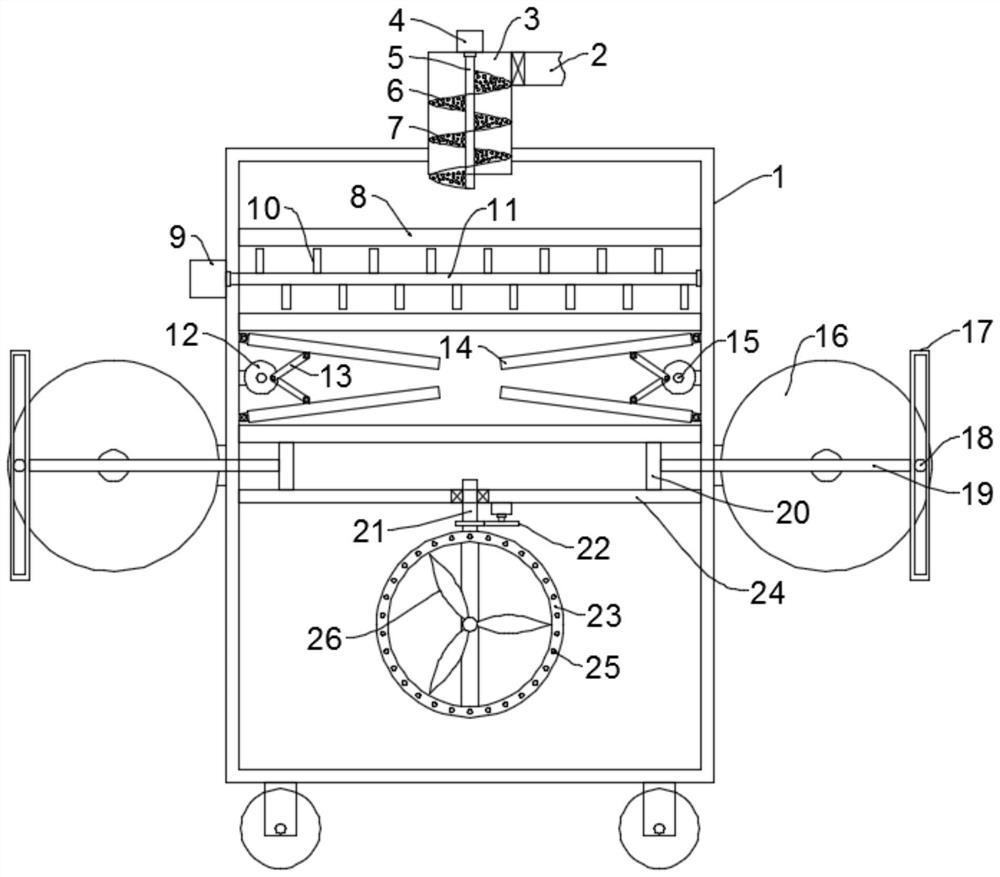

[0028] see figure 2, In the embodiment of the present invention, a catalytic combustion treatment device for adsorbing exhaust gas includes a box body 1. The bottom of the box body 1 is evenly and symmetrically fixed with rollers to facilitate the movement of the device. A box door is installed on the box body 1. Preferably, it is connected to the box body 1 through hinges and buckles. The box body 1 is divided into an adsorption chamber and a catalytic combustion chamber by a horizontally arranged partition plate 24. The partition plate 24 is provided with a communication pipe 21 for connecting the adsorption chamber and the catalytic combustion chamber. , the adsorption chamber is located above the catalytic combustion chamber, and an air intake unit is installed on the top of the box 1 . In this embodiment, the air intake unit includes a dispersion cylinder 3 , a first motor 4 , a first rotating shaft 5 and auger blades 6 The dispersion cylinder 3 is fixedly installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com