Intelligent desalting system for mine water

A mine water and smart technology, applied in the field of water treatment, can solve the problems of cumbersome operation management procedures, difficult to judge the degree of crystallization of the evaporative crystallization system, and difficult to accurately control the discharge time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

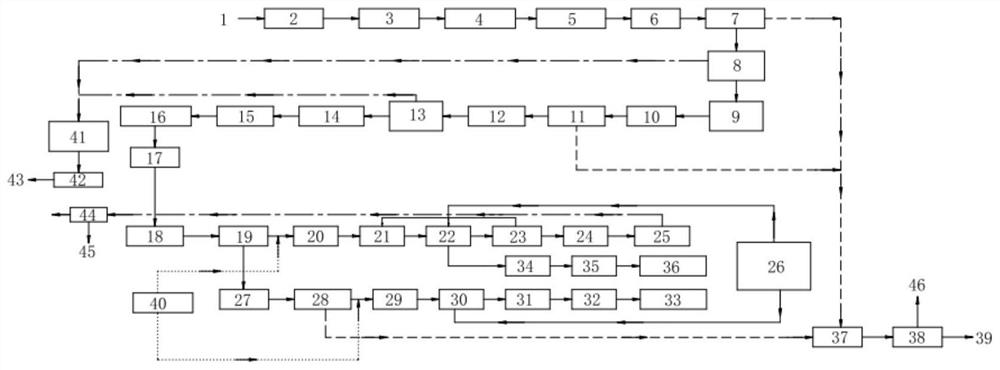

[0043] A smart desalination system for mine water, including a first-level advanced treatment system, a second-level advanced treatment system, and a smart evaporation crystallization system connected in sequence;

[0044] The first-level advanced treatment system is used to filter, concentrate and remove impurities from mine water, and the second-level advanced treatment system is used to filter, desalinate, concentrate, remove ammonia nitrogen, remove all silicon, and remove COD from mine water. Smart evaporation and crystallization system It is used to separate monovalent salt and divalent salt from mine water and obtain monovalent ion crystal salt and divalent ion crystal salt through evaporation and crystallization;

[0045] The intelligent evaporation and crystallization system includes an online monitoring system for fluorescent agents and crystals. The online monitoring system for fluorescent agents and crystals is used to monitor the crystal bonding process in real tim...

Embodiment 2

[0047] like figure 1 As shown, a smart desalination system for mine water, the size of the regulating pool 2 is 50.0m×50.0m×6.0m, the effective water depth is 5.3m, the reinforced concrete structure, and the effective volume is 13250m 2 ; Lifting pump room 3 is equipped with three centrifugal pumps (3 for use and 1 for standby), with a flow rate of 550m 3 / h, the head is 58m, the power is 132kW, the speed is 1485r / min; the design flow rate of a single multi-media filter 4 is 90m 3 / h, the diameter is 3.2m, 16 for 1 standby; the design flow rate of a single activated carbon filter 5 is 90m 3 / h, the head is 40m, the power is 15kw, the primary ultrafiltration system 6 uses Longyuan ultrafiltration membrane, and the flow rate is 234m 3 / h, 4 uses and 1 standby, the cut-off pore size is 0.03μm, the filtration precision is high, the design flux is 30-120LMH, and the nominal area is 40m 2 , the recovery rate is 92%, and the filtration direction is outside in and inside out; the p...

Embodiment 3

[0049] like figure 1 As shown, a smart desalination system for mine water is taken as an example of the Bulianta Mine Water Standard Improvement Project in Yijinhuoluo Banner, Ordos City. The influent water volume of this project is 30,000m 3 / d, the incoming water sources of the project mainly include two types of water bodies, among which the effluent of Bulianta Mine Water Sewage Treatment Plant is 25000m 3 / d, the effluent of Shangwan Mine Water Sewage Treatment Plant is 5000m 3 / d, the mine water pretreatment effluent 1 of the project has been formed after the pretreatment of the sewage treatment plant in the early stage; the mine water pretreatment effluent 1 is passed into the adjustment pool 2 to adjust the water body entering the advanced treatment workshop and balance the water quality, mainly for the influent water body The pH of the water body is adjusted and neutralized; after the water body is adjusted by the regulating tank, it is lifted to the first-level mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com