Multi-layer feeding process method of hot-press grinding rail grinding wheel

A process method and technology of grinding wheel, applied in abrasives, grinding devices, manufacturing tools, etc., to achieve good wear resistance, reduce resin loss, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

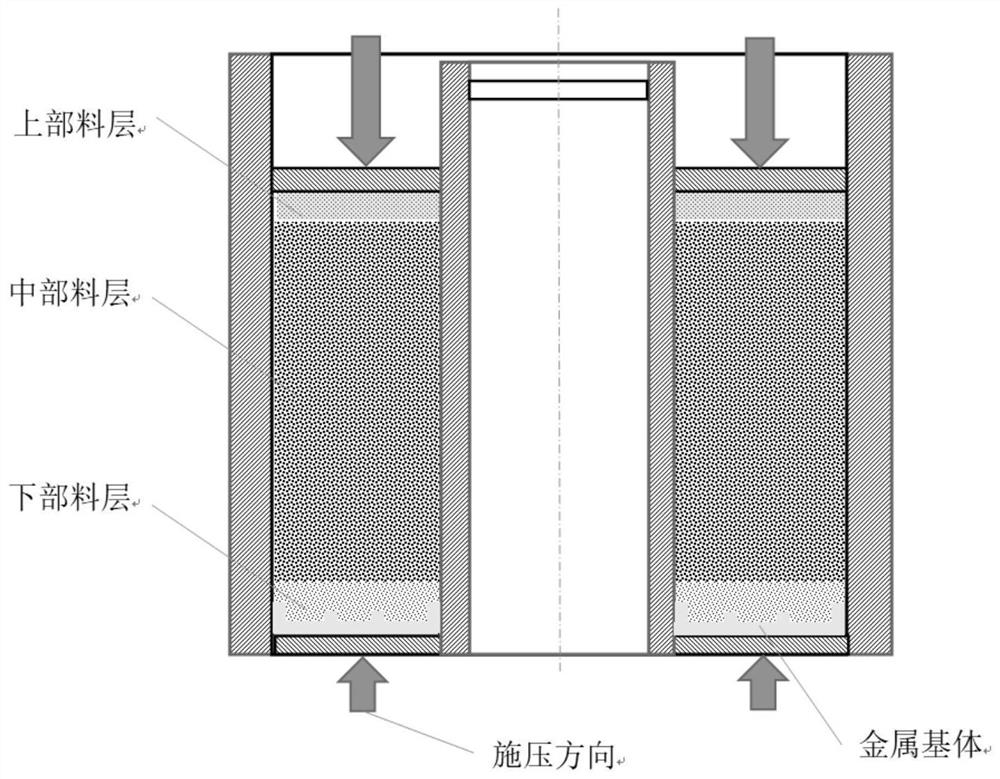

Method used

Image

Examples

Embodiment 1

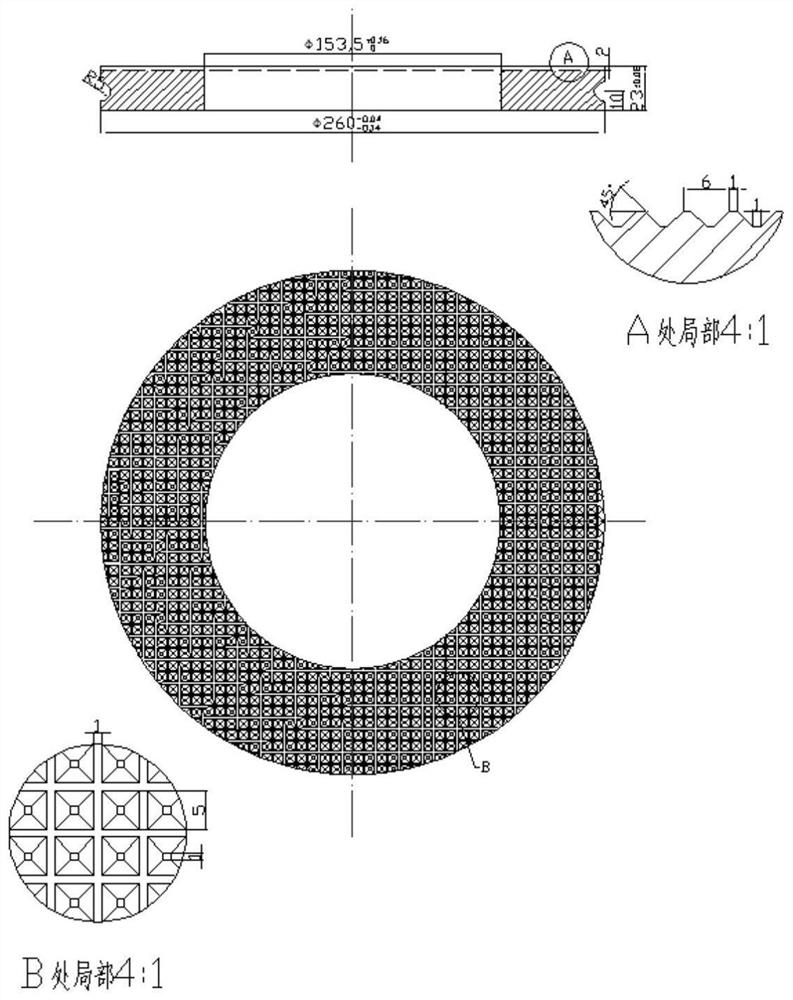

[0043] The rail grinding wheel for the production of GMC96X grinding car is 260×90×153ZA14Y3B 50m / s, and the grinding service life should reach at least 130km.

[0044] 1) Design and calculate the volume of each material layer according to the total thickness of the grinding wheel, the thickness of the clamping part and the process requirements. The data is shown in the following table:

[0045] Layer Thickness and Volume Table

[0046]

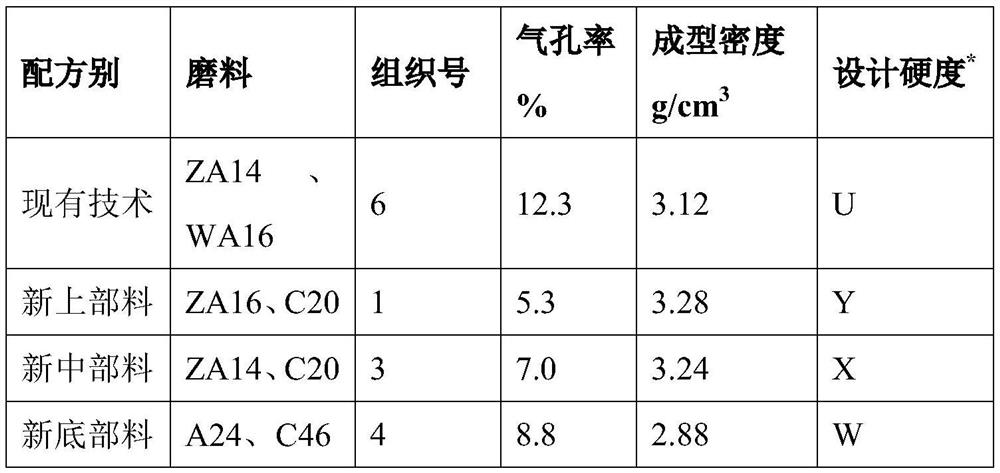

[0047] 2) According to the designed hierarchical formula with different characteristics, the weight percentage of each component is calculated from the volume percentage, and then the respective feeding amounts are calculated according to the molding density, and the batching list is issued for the mixing operation.

[0048] The weight percentage is calculated from the volume percentage, and the total 100% weight ratio of each component can be calculated item by item as follows: Wi=Vi·di / r

[0049] In the formula: Wi—the weight percentag...

Embodiment 2

[0054] For rail grinding wheel 250×75×150 ZA16Y3B 50m / s grinding service life should reach at least 120km. This is an end-face grinding wheel with no metal base and clamped on the outer circumference.

[0055] 1) Design and calculate the volume of each material layer according to the total thickness of the grinding wheel, the thickness of the clamping part and the process requirements. The data is shown in the following table:

[0056] Layer Thickness and Volume Table

[0057]

[0058] 2) According to the designed hierarchical formula with different characteristics, the weight percentage of each component is calculated from the volume percentage, and then the respective feeding amounts are calculated according to the molding density, and the batching list is issued for the mixing operation.

[0059] 3) Weigh the layered feeding weight of each grinding wheel blank separately, cast the bottom material, the middle layer material and the upper material in sequence and spread ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com