Gas-liquid-solid three-phase stirred tank reactor

A stirred tank, gas-liquid-solid technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc. Problems such as normal reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

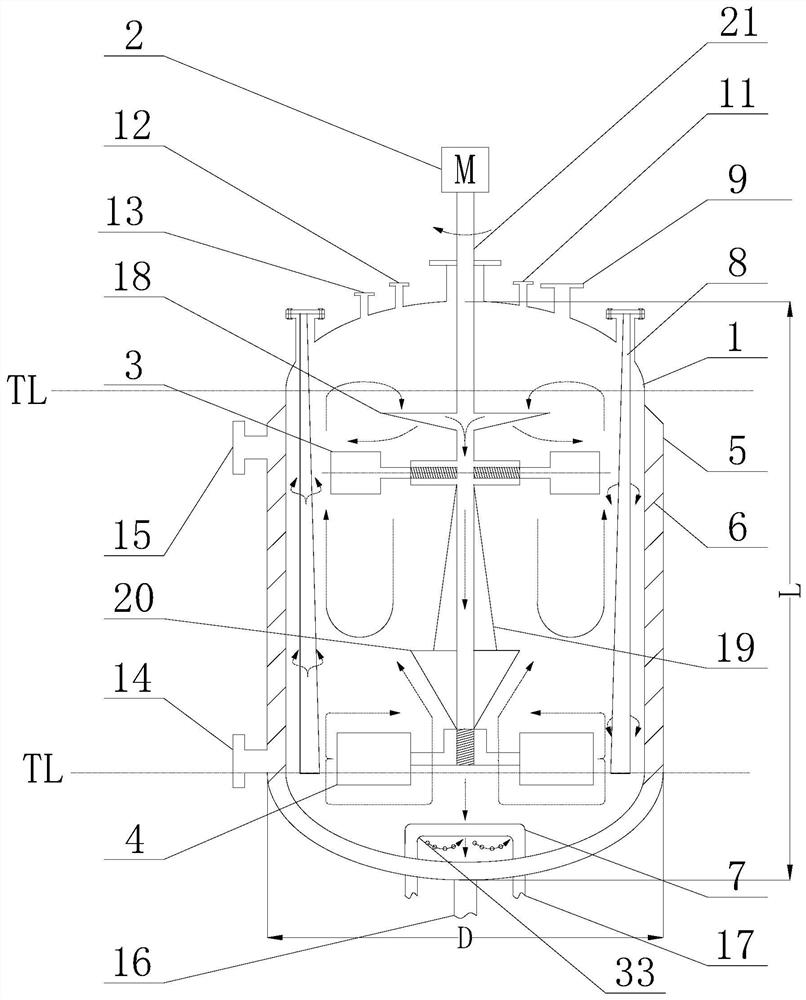

[0147] A kind of ammoniation stirred tank reactor for preparing glycine

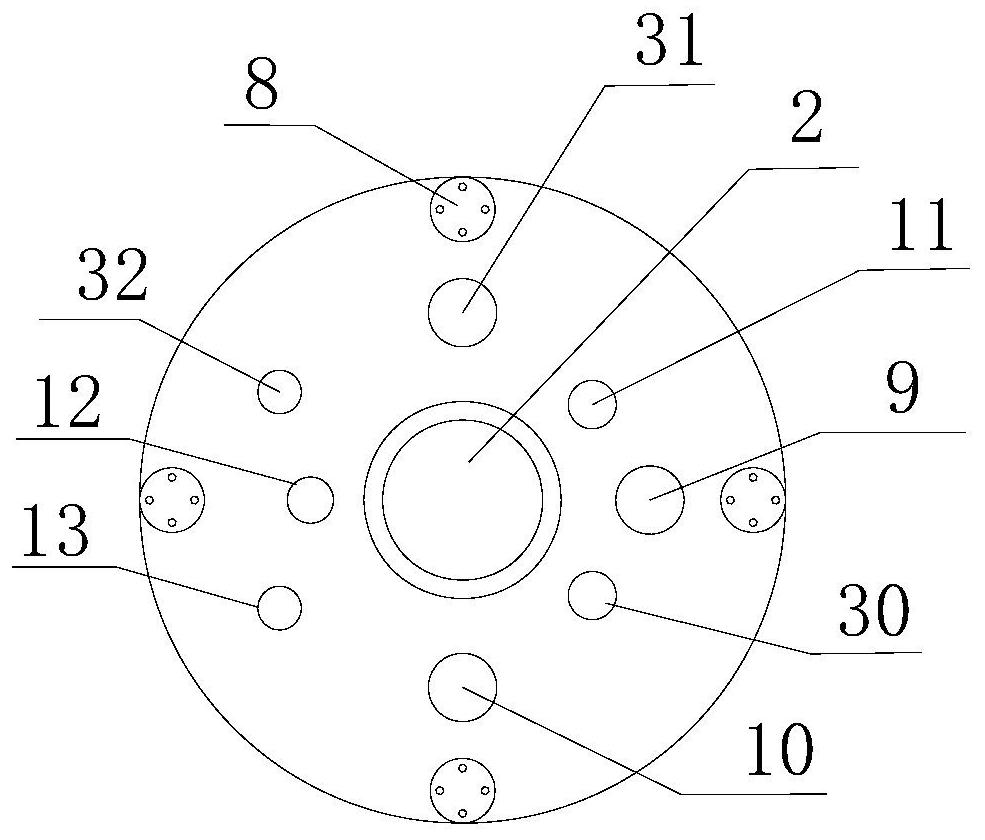

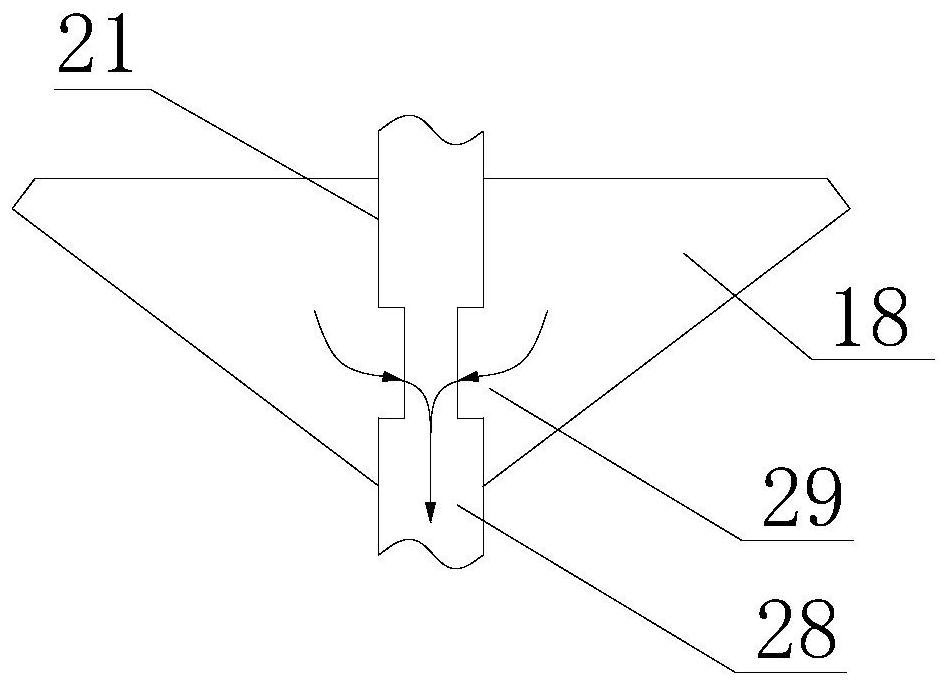

[0148] Ammonia stirred tank reactor volume is 1m 3 (height 1.26m, diameter 1m); 4 deflector refinement plates (width 0.1m, thickness 0.003m) are inserted into the kettle; the angle of the inclined blade stirring blade is 45°, the blade is 4 pieces, the diameter is 0.6m, and the distance from the kettle The distance from the TL line on the upper part of the kettle body is 0.5m; the number of diversion thinning paddle blades is 6 pieces, the diameter is 0.5m, and the distance from the TL line on the upper part of the kettle body is 1m; the distance from the annular gas injector to the TL line at the bottom of the kettle body is 0m, and there are 700 injection holes, the outer diameter of the injector is 0.5m, the inner diameter is 0.4m, the diameter of the ring pipe is 0.1m, and the diameter of the injection hole is 0.003m; m, the height is 0.25m; the height of the discharge inlet is 0.2m, and the number ...

Embodiment 2

[0150] A kind of ammoniation stirred tank reactor for preparing glycine

[0151] Ammonia stirred tank reactor volume is 20m 3 (height 3.41m, diameter 2.7m); 4 deflector refinement plates (width 0.15m, thickness 0.004m) are inserted into the kettle; the angle of the inclined blade stirring blade is 45°, the blade is 6 pieces, the diameter is 1.62m, the distance The distance from the TL line on the upper part of the kettle body is 1.36m; the number of diversion thinning paddle blades is 6 pieces, the diameter is 1.35m, and the distance from the TL line on the upper part of the kettle body is 2.73m; the distance from the annular gas injector to the TL line at the bottom of the kettle body is 0m, There are 2790 injection holes, the outer diameter of the injector is 1.35m, the inner diameter is 1.05m, the diameter of the ring pipe is 0.3m, and the diameter of the injection hole is 0.004m; The height is 1.08m, and the height is 0.68m; the height of the discharge inlet is 0.35m, and t...

Embodiment 3

[0153] A kind of ammoniation stirred tank reactor for preparing glycine

[0154] Ammonia stirred tank reactor volume is 40m 3 (height 4.3m, diameter 3.4m); 6 deflector refinement plates (width 0.2m, thickness 0.006m) are inserted into the kettle; the angle of the inclined blade stirring blade is 45°, the blade is 6 pieces, the diameter is 2.04m, the distance The distance from the TL line on the upper part of the kettle body is 1.36m; the number of diversion thinning paddle blades is 8 pieces, the diameter is 1.7m, and the distance from the TL line on the upper part of the kettle body is 3.44m; the distance from the annular gas injector to the TL line at the bottom of the kettle body is 0m, There are 2500 injection holes, the outer diameter of the injector is 1.7m, the inner diameter is 1.3m, the diameter of the ring pipe is 0.4m, and the diameter of the injection hole is 0.005m; The height is 1.33m, and the height is 0.86m; the height of the discharge inlet is 0.43m, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com