High-strength steel having excellent resistance to sulfide stress cracking, and method for manufacturing same

A stress corrosion cracking and anti-sulfide technology, applied in the field of thick steel, can solve the problems of reduced surface hardness and reduced steel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0160] Billets having alloy compositions shown in Table 1 below were prepared. At this time, the content of the alloy composition is by weight %, and the balance is Fe and unavoidable impurities. According to the conditions in Table 2, the prepared steel slabs were heated, hot-rolled, and cooled to obtain various steel products.

[0161] Table 1:

[0162]

[0163] (In Table 1, P*, S*, N*, Ca* are expressed in ppm. In addition, Ar3=910-310×C-80×Mn-20×Cu-15×Cr-55×Ni-80×Mo+ 0.35×(thickness (mm)-8), Ar1=742-7.1×C-14.1×Mn+16.3×Si+11.5×Cr-49.7×Ni)

[0164] Table 2:

[0165]

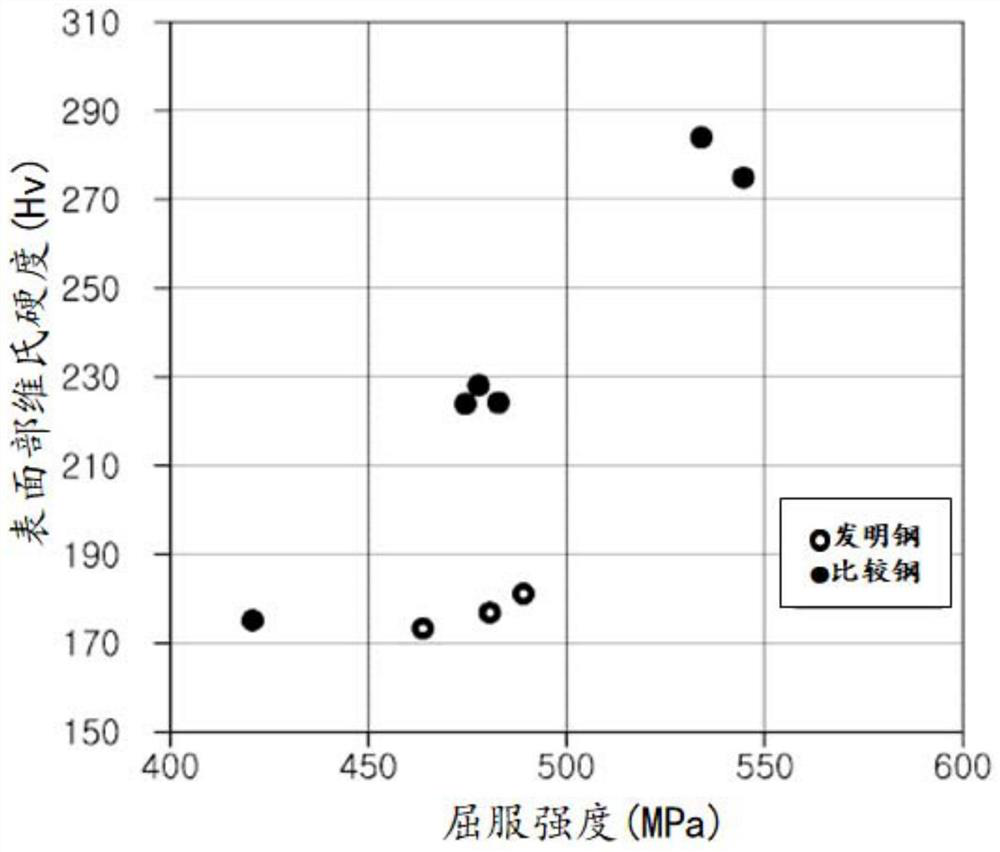

[0166] The yield strength (YS), the Vickers hardness and the sulfide stress cracking resistance of the surface part and the center part were measured for each steel material obtained above, the microstructure was observed, and the results are recorded in Table 3.

[0167] In this case, the yield strength refers to the yield strength when the elongation under load (under-load) is 0.5%. For the tensile...

Embodiment 2

[0178] Billets having alloy compositions shown in Table 4 below were prepared. At this time, the content of the alloy composition is by weight %, and the balance is Fe and unavoidable impurities. According to the conditions in Table 5, the prepared steel slabs were heated, hot-rolled, and cooled to obtain various steel products.

[0179] Table 4:

[0180]

[0181] (In Table 4, P*, S*, N*, Ca* are expressed in ppm. In addition, Ar3=910-310×C-80×Mn-20×Cu-15×Cr-55×Ni-80×Mo+ 0.35×(thickness (mm)-8), Ar1=742-7.1×C-14.1×Mn+16.3×Si+11.5×Cr-49.7×Ni)

[0182] table 5:

[0183]

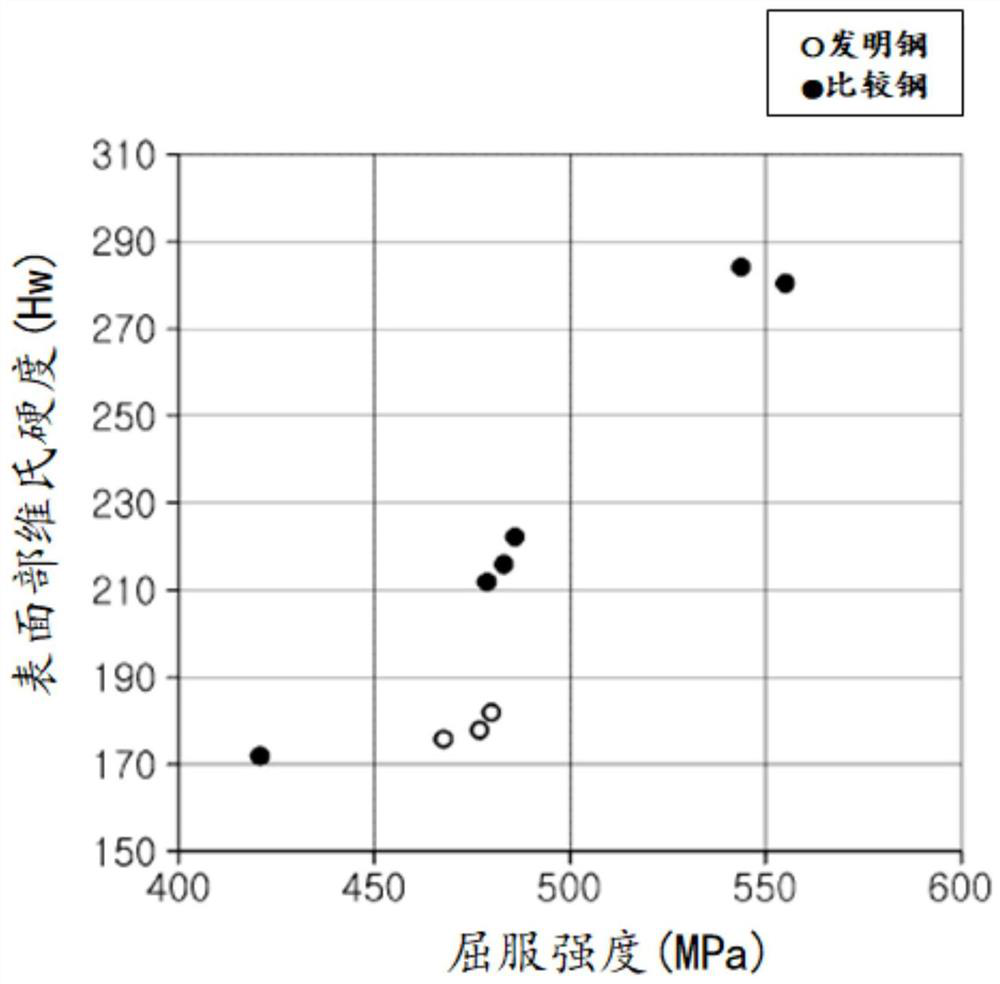

[0184]The yield strength (YS), the Vickers hardness of the surface and the center, and the resistance to sulfide stress cracking were measured for each of the steel materials prepared above, and the microstructure was observed. The results are recorded in Table 6 below.

[0185] In this case, the yield strength refers to the yield strength when the elongation (under-load, under load) is 0.5%. For the...

Embodiment 3

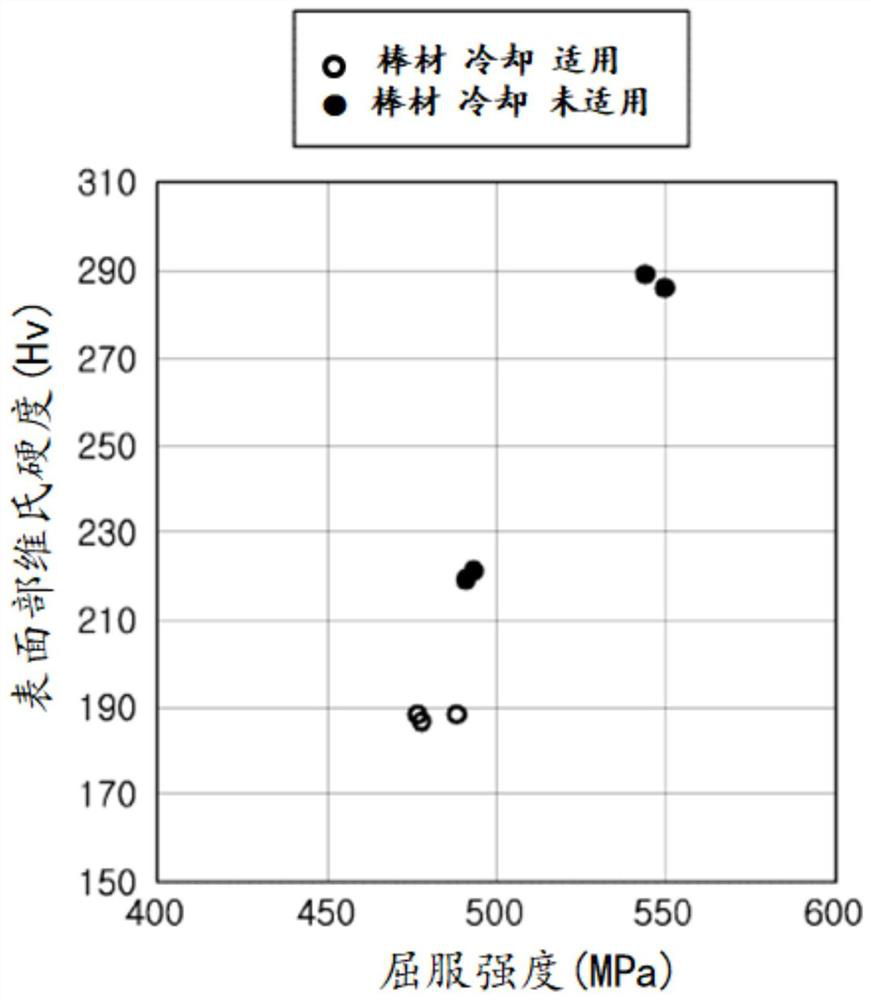

[0196] Billets having alloy compositions shown in Table 7 below were prepared. At this time, the content of the alloy composition is by weight %, and the balance is Fe and unavoidable impurities. According to the conditions in Table 8, the prepared steel slabs were heated, hot-rolled, and cooled to obtain various steel products. At this time, the steel billet that has completed the heating is used for rough rolling under normal conditions to obtain bars (bar), and then the bars of some steel types are cooled and then hot-rolled. The above-mentioned cooled bar (bar) is reheated to the austenite single-phase region.

[0197] Table 7:

[0198]

[0199] (In Table 7, P*, S*, N*, Ca* are expressed in ppm. In addition, Ar3=910-310×C-80×Mn-20×Cu-15×Cr-55×Ni-80×Mo+ 0.35×(thickness (mm)-8), Ar1=742-7.1×C-14.1×Mn+16.3×Si+11.5×Cr-49.7×Ni)

[0200] Table 8:

[0201]

[0202] The yield strength (YS), the Vickers hardness of the surface part and the central part, and the resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com