A Noise Reduction Transducer Device and Method Combining Helmholtz Resonance Effect and Venturi Effect

A technology of Venturi effect and resonance effect, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the conversion of single physical effect energy, the unstable fixation method , high cost and other problems, to achieve the effect of convenient and time-saving installation and line connection, convenient and reliable fixing method, and improved energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

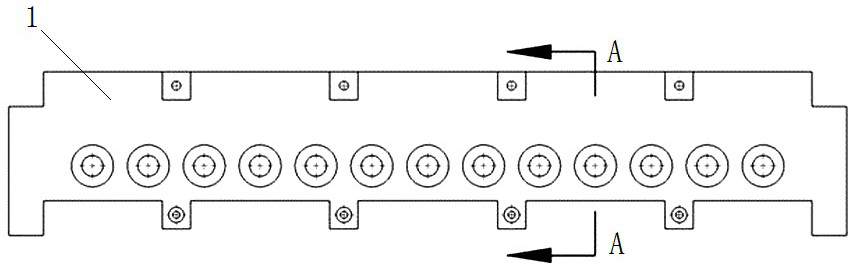

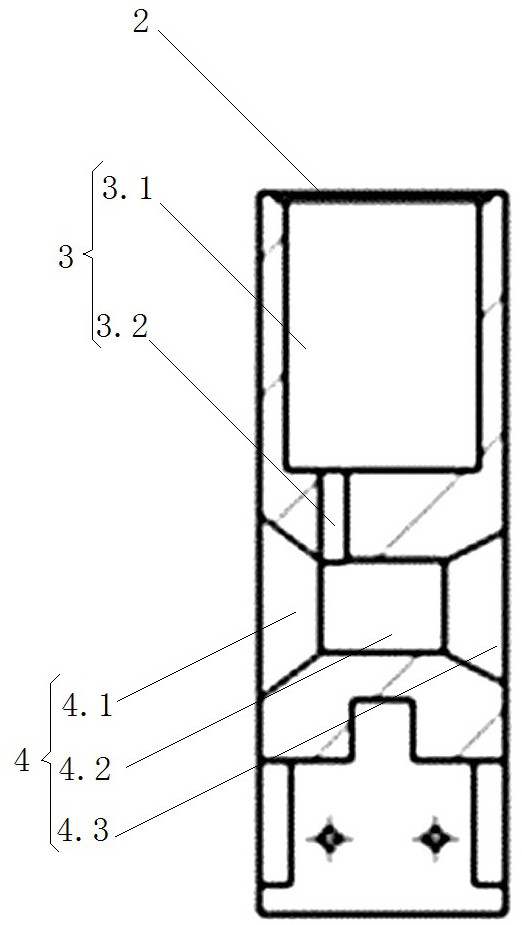

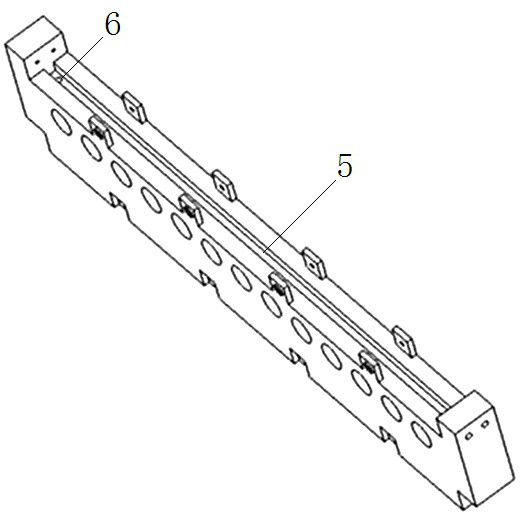

[0041] This embodiment provides a noise-reducing transduction device combined with the Helmholtz resonance effect and the Venturi effect, including an acoustic power generation noise reduction board 1 and a piezoelectric sheet 2, and the acoustic power generation noise reduction board 1 is provided with a A working unit composed of a Helmholtz resonator 3 and a Venturi channel 4; the Helmholtz resonator 3 is vertically arranged, including a connected Helmholtz resonator 3.1 and a neck 3.2, and the Helmholtz resonator 3.1 The top is closed by the piezoelectric sheet 2 arranged on the opening of the top surface of the acoustic power generation noise reduction board 1; the Venturi channel 4 traverses through the front and back of the acoustic power generation noise reduction board 1, including the connected inlet section 4.1 and the throat 4.2 With the outlet section 4.3, the throat 4.2 communicates with the neck 3.2 of the Helmholtz resonator 3.

[0042] Further, the Helmholtz r...

Embodiment 2

[0055] This embodiment provides a noise reduction transduction method combining the Helmholtz resonance effect and the Venturi effect. The piezoelectric sheet 2 and the External circuit connection;

[0056] According to the Helmholtz resonance effect, when the incident noise is consistent with the natural frequency of the Helmholtz resonator 3, the sound wave passes through the neck 3.2 and presses the gas in the Helmholtz resonator 3.1 to undergo compression, expansion and reciprocating deformation, thereby causing piezoelectric The piece 2 undergoes stretching and compression reciprocating motion, and due to the piezoelectric effect, alternating charges will be generated on the surface of the piezoelectric piece 2, and the piezoelectric piece 2 will be connected in series and parallel, and the current signal will be rectified and transformed to form a direct current to realize noise reduction. Acoustic energy to electrical energy conversion, while achieving noise suppression...

Embodiment 3

[0060] In this embodiment, the overall design of the acoustic power generation and noise reduction board 1 is 600 mm in length, 600 mm in width and 40 mm in thickness.

[0061] The size of the Venturi channel 4 is that the diameter of the inlet section 4.1 is 30 mm, the diameter of the throat 4.2 is 15 mm, the length of the throat 4.2 is 20 mm, and the diameter of the outlet section 4.3 is 25 mm.

[0062] The Helmholtz resonator 3 is designed according to the following formula:

[0063]

[0064] In the formula, f is the Helmholtz resonance frequency, c is the speed of sound, s is the cross-sectional area of the neck, l is the neck height, d is the diameter of the neck section, and v is the volume of the Helmholtz resonant cavity.

[0065] The design dimensions of Helmholtz resonator 3 are: neck 3.2 height 15mm, neck 3.2 section diameter 4mm, Helmholtz cavity 3.1 height 45mm, Helmholtz cavity 3.1 section diameter 31mm, due to Helmholtz The top of the resonant cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com