Wearable mobile energy and preparation method thereof

An energy and textile technology, applied in the field of wearable mobile energy and its preparation, can solve problems such as restricting the development of wearable smart devices, large size, and limited power supply life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

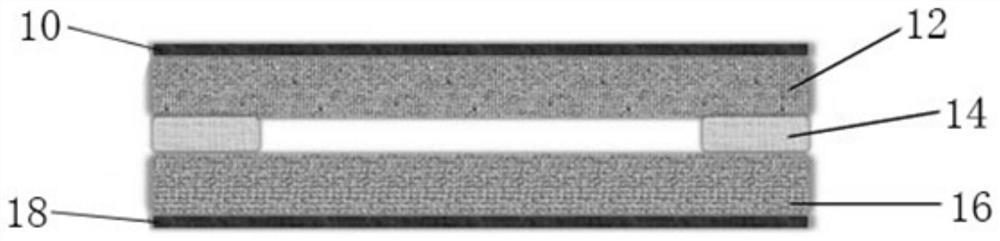

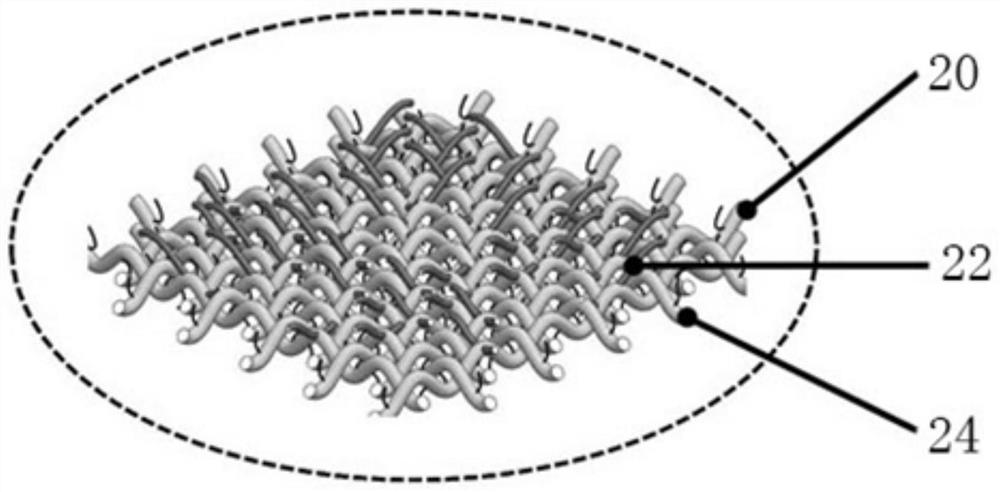

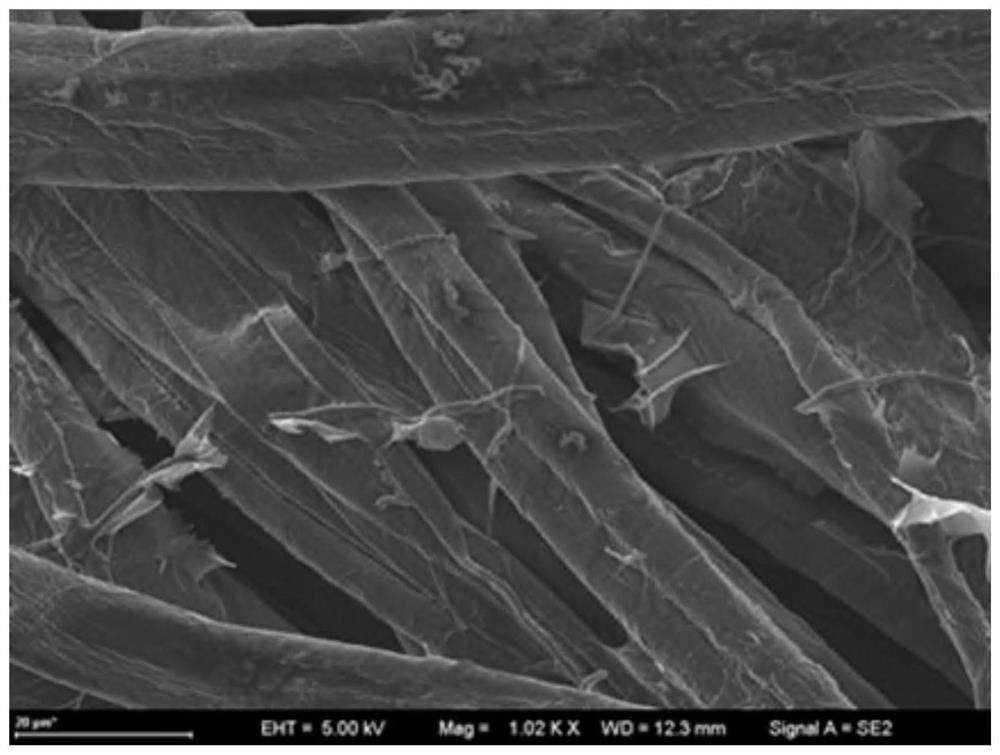

[0051] washing the first cotton fabric in absolute ethanol and deionized water for 30 minutes, and drying in an oven at a drying temperature of 60° C. for 3 hours to obtain a clean first fabric; Prepare a carbon nanotube solution with a concentration of 0.3 mg / mL in a beaker, immerse the first textile in the uniformly mixed carbon nanotube solution, shake it on a shaking table for 30 minutes, take it out, and let it dry naturally for 4 hours, repeating several times Above-mentioned impregnating, shaking and air-drying process, obtain the upper conductive yarn electrode 10 of high conductivity; Repeat above-mentioned steps, obtain the lower conductive yarn electrode 18 of high conductivity; Put 0.1mol / L ferric chloride ( FeCl3) aqueous solution, the second textile fabric of cotton is put into ferric chloride (FeCl 3 ) aqueous solution, vibrated on a shaking table for 30 minutes; the aqueous solution of 0.5%wt sodium dodecylbenzenesulfonate surfactant (SDBS) and 0.1mol / L 3,4-eth...

Embodiment 2

[0053] washing the first textile made of chemical fiber in absolute ethanol and deionized water for 30 minutes, and drying in an oven at a drying temperature of 60° C. for 3 hours to obtain a clean first textile; Configure a graphene solution with a concentration of 60 mg / mL in a beaker, immerse the first textile in the evenly mixed graphene solution, take it out after oscillating on an oscillating table for 30 minutes, and let it dry naturally for 4 hours. Repeat the above immersion, Oscillation and air-drying process, obtain highly conductive upper conductive yarn electrode 10; repeat the above steps to obtain highly conductive lower conductive yarn electrode 18; put 0.1mol / L ferric chloride (FeCl3) aqueous solution in the beaker , put the second textile made of chemical fiber into ferric chloride (FeCl 3 ) aqueous solution, vibrated on a shaking table for 30 minutes; the aqueous solution of 0.5%wt sodium dodecylbenzenesulfonate surfactant (SDBS) and 0.1mol / L 3,4-ethylenedio...

Embodiment 3

[0056] washing the first textile made of silk in absolute ethanol and deionized water for 30 minutes, and drying in an oven at a drying temperature of 60° C. for 3 hours to obtain a clean first textile; Configure a silver nanowire solution with a concentration of 10 mg / mL in a beaker, immerse the first textile in the uniformly mixed silver nanowire solution, take it out after oscillating on an oscillating table for 30 minutes, and let it dry naturally for 4 hours. Repeat the above steps several times. Dipping, shaking and air-drying process, obtain the upper conductive yarn electrode 10 of high conductivity; Repeat the above steps, obtain the lower conductive yarn electrode 18 of high conductivity; Put 0.2mol / L ferric chloride (FeCl in the beaker ) aqueous solution, the second textile fabric of silk material is put into ferric chloride (FeCl 3 ) aqueous solution, vibrated on a shaking table for 30 minutes; the aqueous solution of 0.5%wt sodium dodecylbenzenesulfonate surfactan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com