Equipment fault prediction method and system

A prediction method and fault prediction technology, applied in the direction of instruments, biological neural network models, character and pattern recognition, etc., can solve the problems of heavy workload in factory network layout, inability to specifically locate equipment failures, and inability to classify equipment damage levels, etc., to achieve The effect of improving the task success rate, improving the equipment integrity rate, and shortening the maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to illustrate the present invention more clearly, relevant concepts and definitions are explained first.

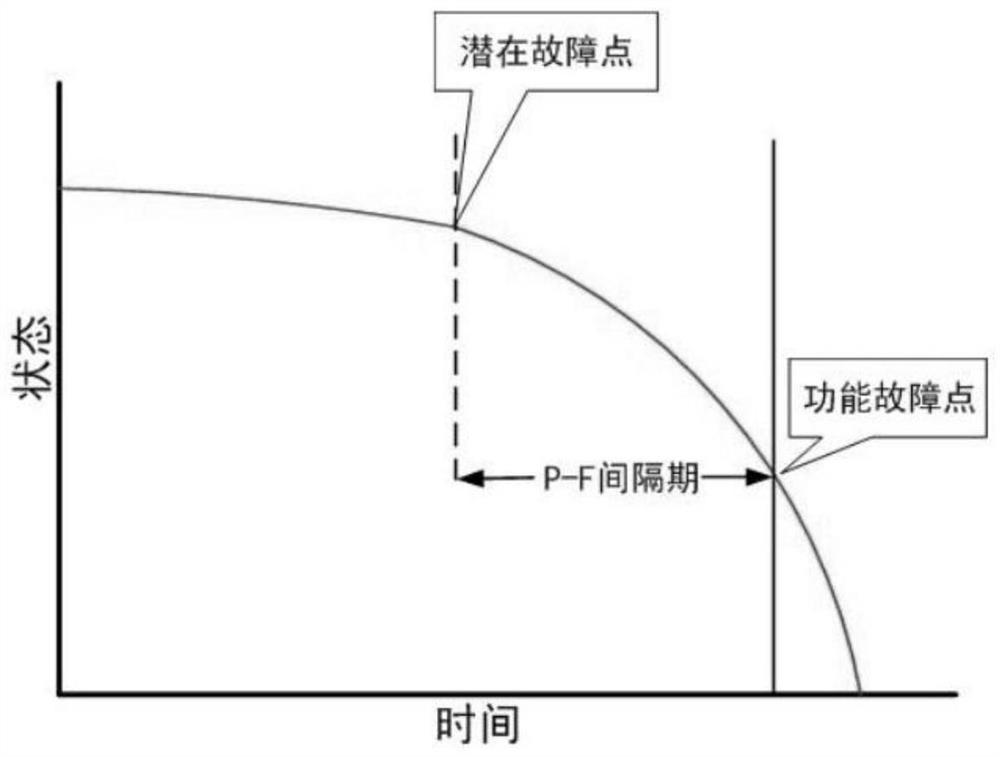

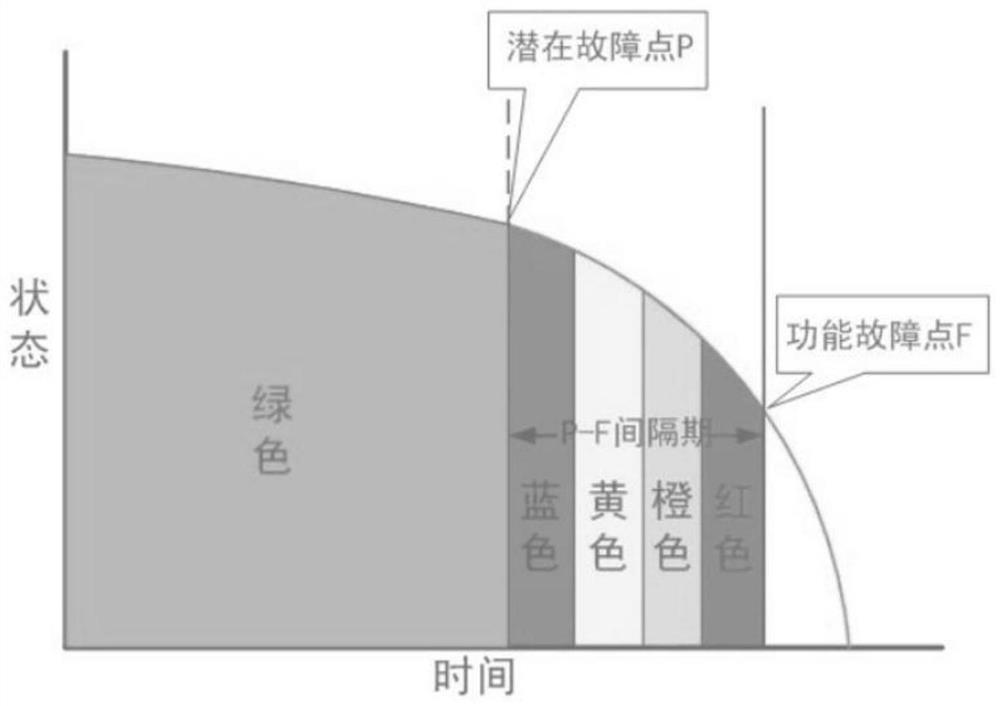

[0045] The prerequisite for fault prediction is that for some faults, the performance degradation is a gradual degradation process, that is, there is a "potential fault-functional fault" interval, such as figure 1As shown, this process is also the P-F interval. The "P" point is a potential fault point, which is the point where the fault can be found. Before that, the fault does not have any symptoms. Regression to point of functional failure "F", i.e. the device is no longer usable. The existence of "PF interval" is a prerequisite for prediction of complex equipment, that is, state-based AI prediction is only applicable to faults with "PF interval". Equipment performance is also a process of gradual degradation. After a certain time point (potential failure point "P"), alarm information and log information will be generated, and the performance will begi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com