Dry preparation method for oxidized solid electrolyte and oxidized solid electrolyte

A solid electrolyte and dry method technology, applied in the field of materials, can solve the problems of increased preparation time, increased safety accidents, and complicated preparation process, and achieve the effect of simple and easy preparation method, high safety and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

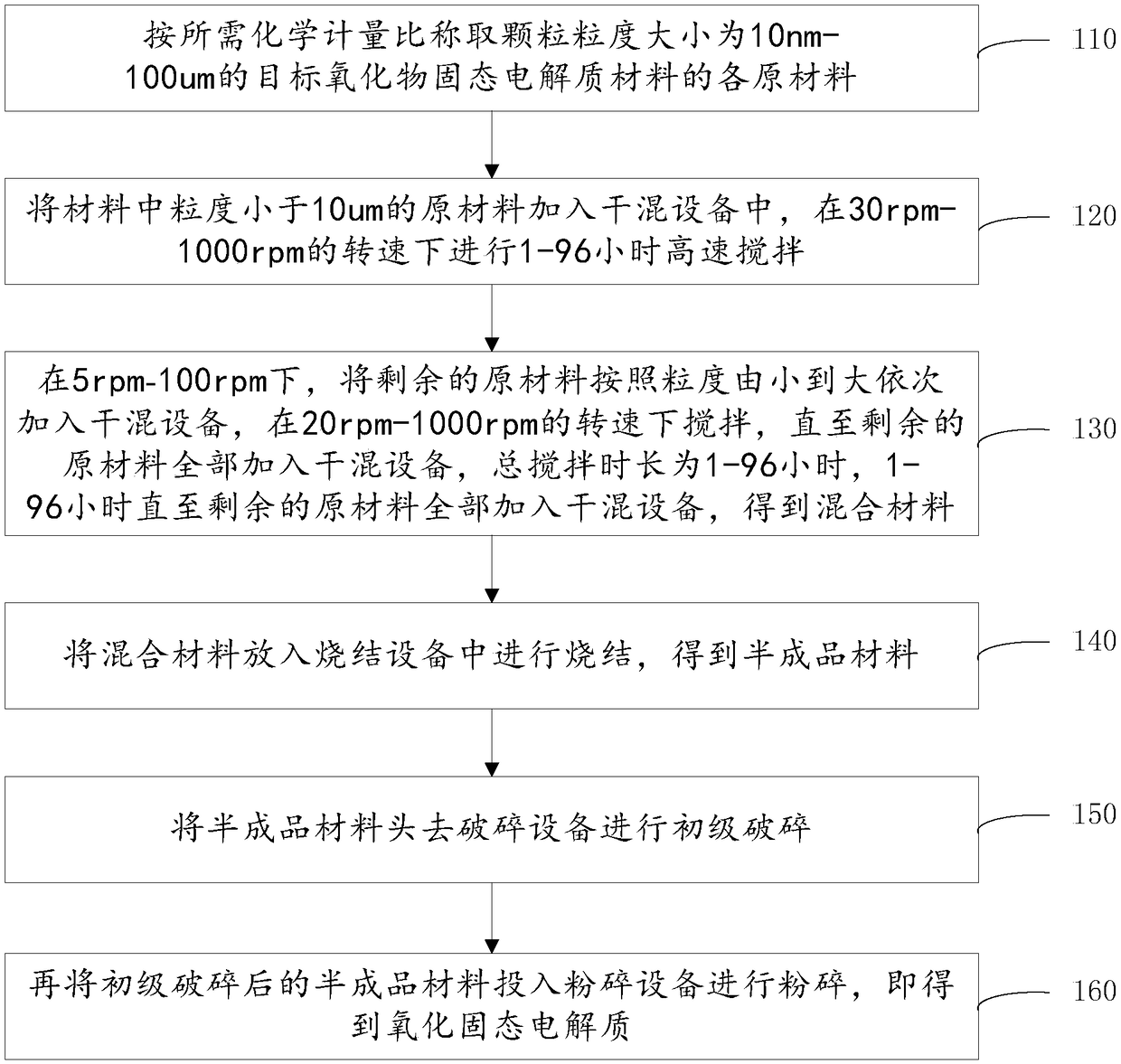

[0032] This embodiment provides a dry method for preparing an oxidized solid electrolyte, such as figure 1 As shown, the steps include:

[0033] Step 110, weighing each raw material of the target oxide solid electrolyte material with a particle size of 10nm-100um according to the required stoichiometric ratio;

[0034] Among them, the raw materials include oxides, hydroxides, carbonates, phosphates or ammonium salts of Li, A, and B;

[0035] Wherein, A is one or more of Zr, Cr, Sn, B is one or more of Si, S, P, used to prepare LISICON solid state electrolyte;

[0036] Or, A is one or more of Al, Y, Ga, Cr, In, Fe, Se, La, B is one of Ti, Ge, Ta, Zr, Sn, Fe, V, metal hafnium Hf or more, used to prepare NASICON solid state electrolyte;

[0037] Alternatively, A is one or more of La, Al, Mg, Fe, Ta, and B is one or more of Ti, Nb, Sr, and Pr, to prepare a perovskite-type solid electrolyte;

[0038] Alternatively, A is one or more of La, Ca, Sr, Ba, and K, and B is one or more...

Embodiment 2

[0056] In this example, the preparation method described in Example 1 was used to prepare an oxidized solid electrolyte material.

[0057] Weigh 970.96g of lithium carbonate with a particle size of 1um, 446.60g of alumina with a particle size of 500nm, 2098.94g of titanium oxide with a particle size of 1um, and 6046g of ammonium dihydrogen phosphate powder with a particle size of 10um. Put the ammonium dihydrogen phosphate powder in a V-conical screw mixer and mix at a high speed at a speed of 400rpm, and the mixing time is 15 minutes. Then add the titanium oxide powder at a low speed of 20 rpm, and mix at a speed of 400 rpm for 15 minutes. According to the above steps, add lithium carbonate powder and alumina powder in turn. The final rotating speed is 400rpm for 2 hours. Take out the mixed precursor and put it in a box furnace for sintering. Sintering Sintering includes the process of staged heating and staged constant temperature. The specific procedure is: room temperat...

Embodiment 3

[0061] In this example, the preparation method described in Example 1 was used to prepare an oxidized solid electrolyte material.

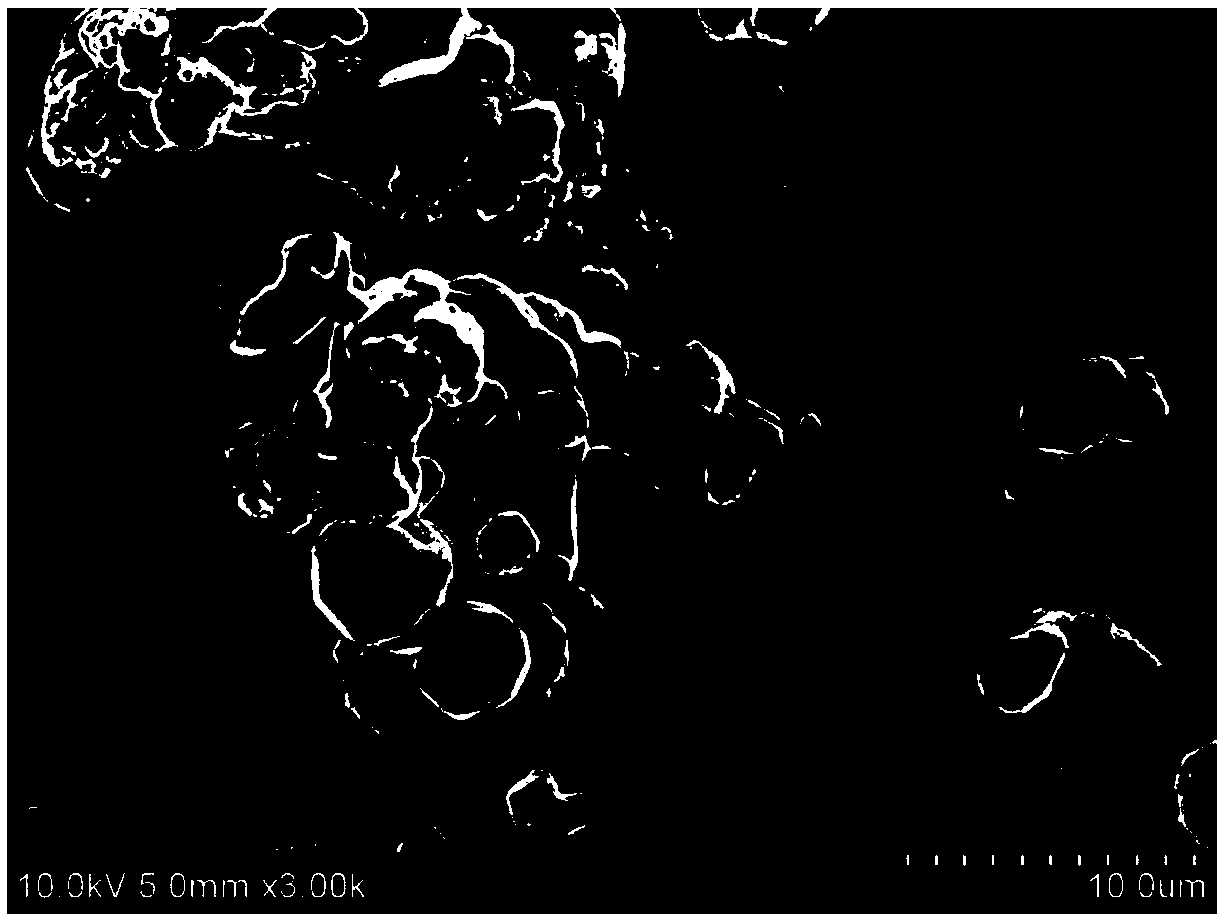

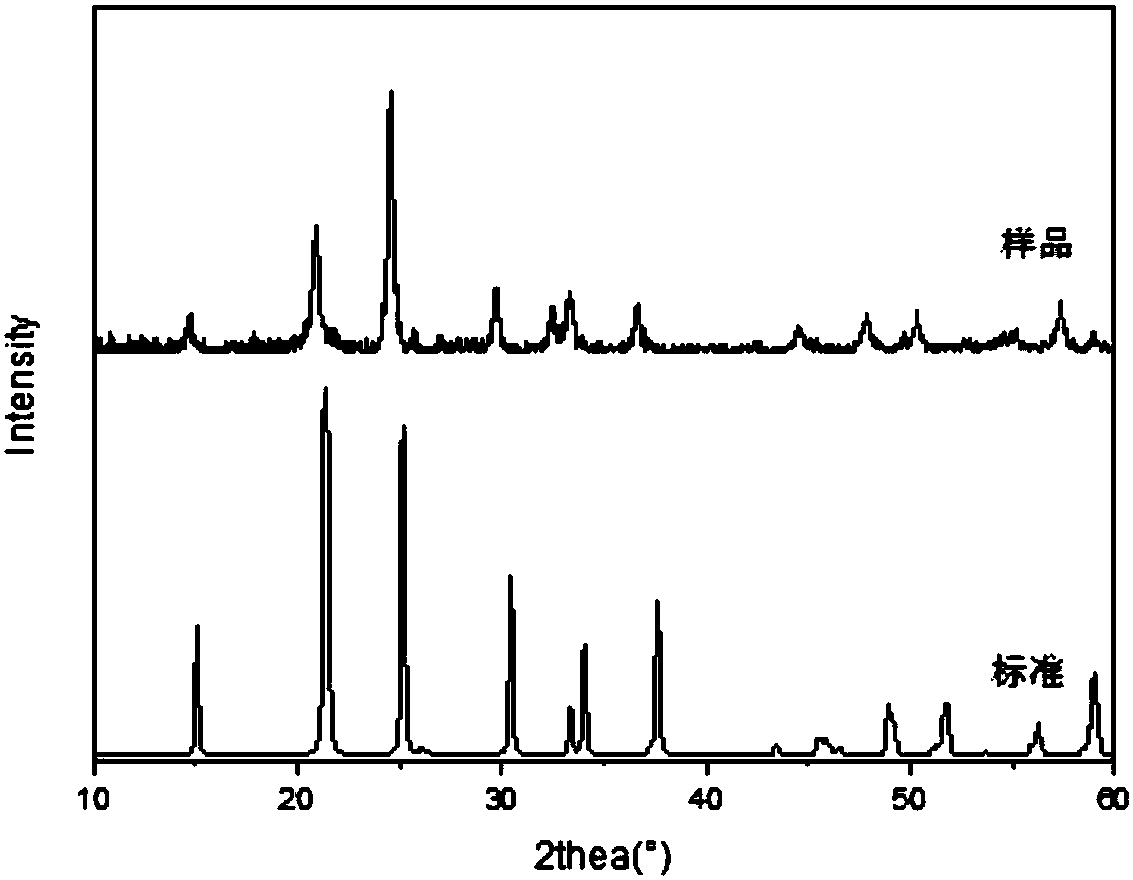

[0062] Weigh 3240.2g of lithium carbonate with a particle size of 2um, 60.667g of alumina with a particle size of 200nm, 5815.8g of lanthanum oxide with a particle size of 4um, and 2932.7g of zirconia powder with a particle size of 500nm. Put the lanthanum oxide powder in a roller mill and stir at a speed of 30 rpm for 4 hours, then stand still, add lithium carbonate powder at a speed of 30 rpm, and mix for 4 hours. According to the above steps, add zirconia and alumina powder in turn. The final rotation speed was 30 rpm, and the mixing time was 24 hours. Take out the mixed precursor and put it in a box furnace for sintering. The sintering program is: room temperature to 900°C, heating rate 3°C / min, heat preservation for 12 hours, heating from 900°C to 1200°C, heating rate 1°C / min, 1200°C heat preservation for 24 hours. The semi-finished produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com