Fault diagnosis method based on multi-head attention and shafting equipment periodicity

A technology for shafting equipment and fault diagnosis, applied in neural learning methods, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as low degree of parallel computing and difficulty in extracting long-distance correlation information, and achieve parallelism High degree of calculation, good fault diagnosis effect, and strong long-distance information ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] An embodiment of the present invention provides a fault diagnosis method based on multi-head attention and periodicity of shafting equipment, including:

[0062] S101: Collect several cycles of to-be-diagnosed samples of the shafting equipment, and perform standardized processing after adding periodic information of the shafting equipment to the to-be-diagnosed samples;

[0063] S102: Using the standardized sample data as an input of the multi-head attention fault diagnosis model to obtain a fault diagnosis result.

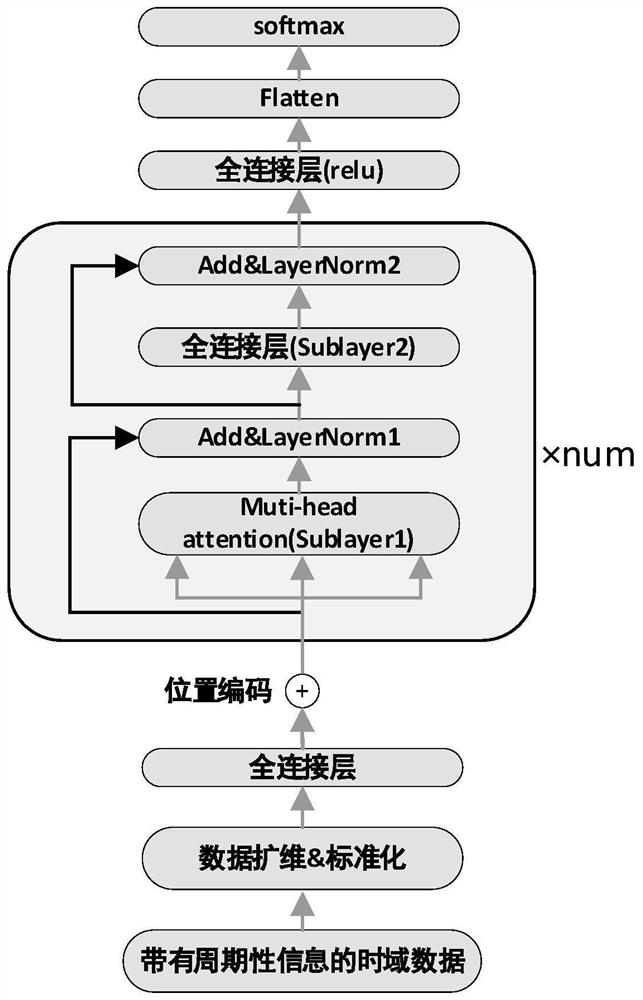

[0064] Specifically, the structure of the multi-head attention fault diagnosis model is as follows figure 1 As shown, the offline training process of the multi-head attention fault diagnosis model includes the following steps:

[0065] Step A1: Perform nT independent sampling on the shafting equipment through m sensors to obtain the historical data matrix X of the shafting equipment 0 , and in matrix X 0 The cycle information of shafting equipment is add...

Embodiment approach

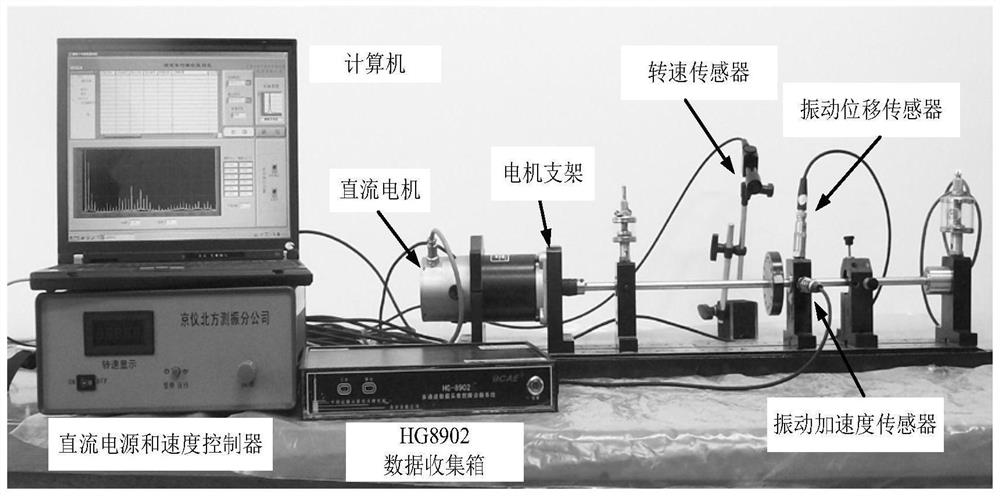

[0075] Taking the ZHS-2 multifunctional motor flexible rotor test bench as the shafting equipment as an example, the test bench structure is as follows: figure 2 shown. In this embodiment, 8 vibration acceleration sensors installed in the horizontal direction of the rotor support base are used to collect the samples to be diagnosed on the test bench. Specifically, the samples to be diagnosed are the time-domain vibration signals of the rotor of the test bench, and the signals are passed through the HG8902 The collection box is transmitted to the host computer.

[0076] The test bench can simulate various operating modes of shafting equipment, including rotor unbalanced failure mode, ball failure mode, fan broken blade failure mode, base loose failure mode, gear broken teeth failure mode and normal operation mode, etc. Adopt seven operation modes: rotor unbalanced (1 screw), rotor unbalanced (3 screws), rotor unbalanced (5 screws), rotor unbalanced (7 screws), fan blade failu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com