Industrial hole wall defect detection system based on AI and identification algorithm

A defect detection and hole wall technology, applied in the field of defect detection, can solve the problems of high detection error rate, slow detection speed, lack of consistency and reliability, etc., to improve detection speed, improve detection speed, and ensure product quality consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

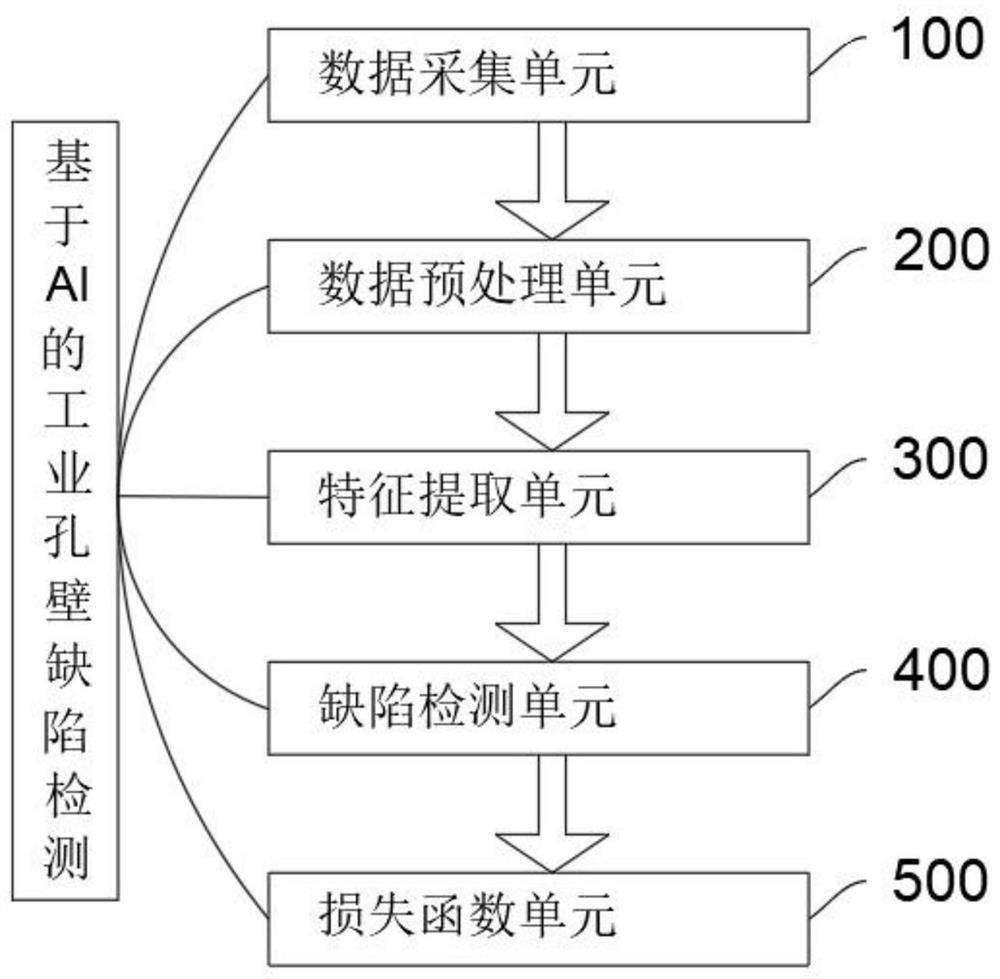

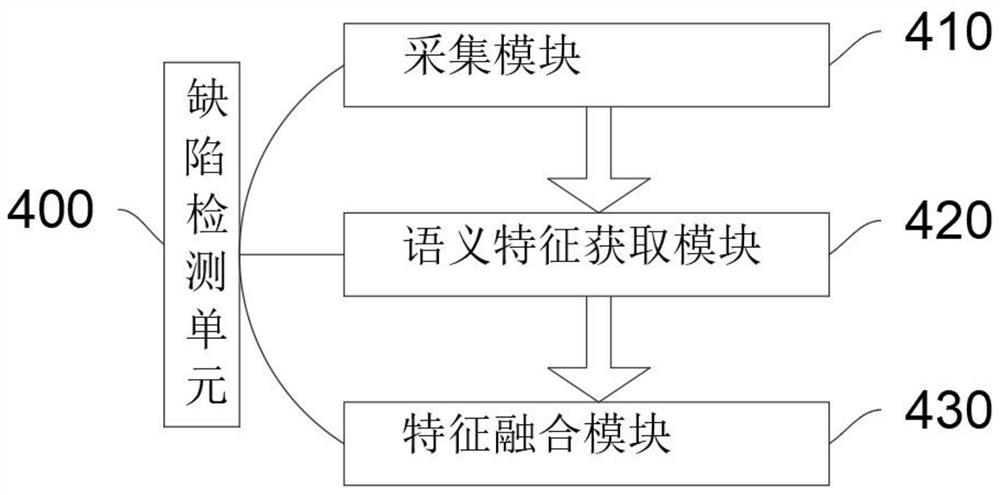

[0061] see Figure 1-Figure 3 As shown, on the one hand, the present invention provides an AI-based industrial hole wall defect detection system, including a data acquisition unit 100, a data preprocessing unit 200, a feature extraction unit 300, a defect detection unit 400, and a loss function unit 500;

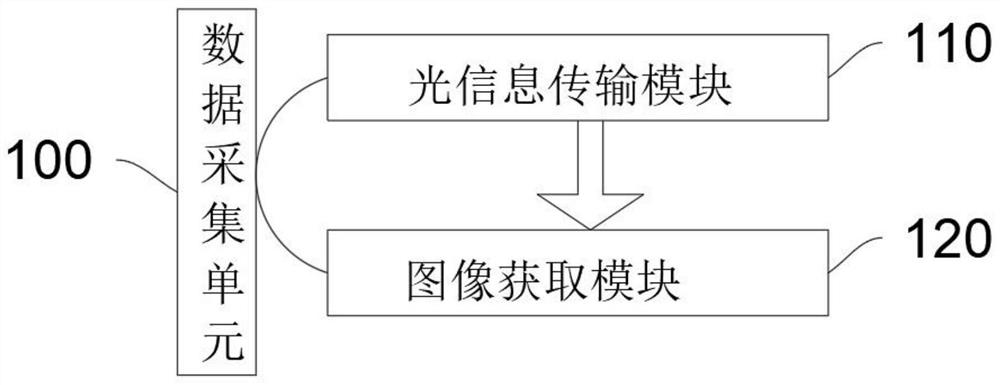

[0062] The data acquisition unit 100 is used to convert the ingested target into an image signal and transmit it to the image processing system, and use artificial intelligence to convert it into a digital signal based on information such as pixel distribution, brightness, and color, and the image processing system performs operations on it to extract the target characteristics, and then obtain detection results or realize feedback control;

[0063] The data preprocessing unit 200 is used to perform data augmentation on the image signal collected by the data acquisition unit 100 through rotation, translation, mirroring, and adjusting the brightness of the picture to increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com