Belt defect detection method and system

A technology of defect detection and belt layer, which is applied in the direction of optical detection of defects/defects, can solve the problems of low tire production efficiency, and achieve the effect of improving production efficiency and defect detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the embodiments of the present invention more obvious and understandable, the following describes the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings For further detailed explanation.

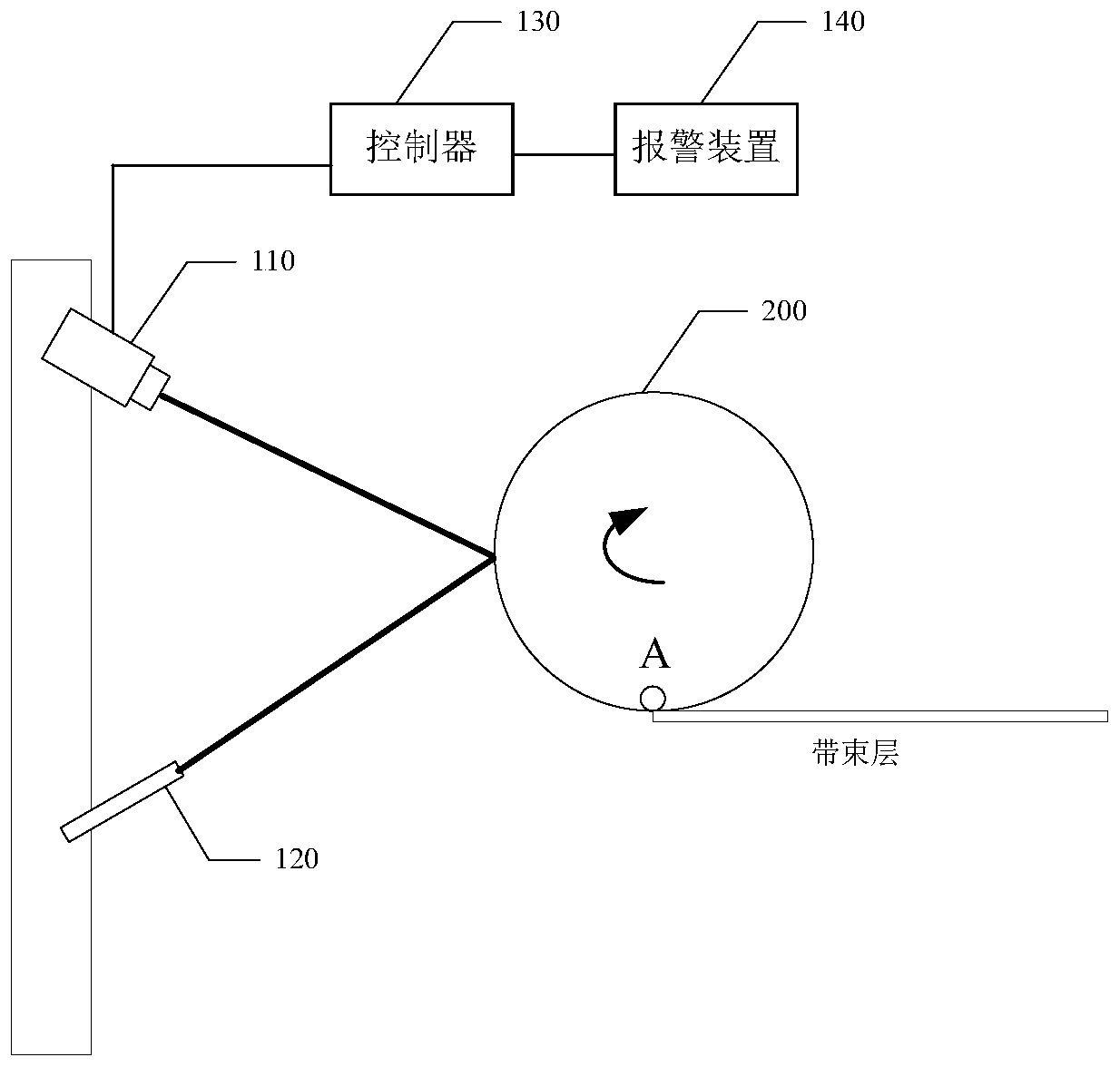

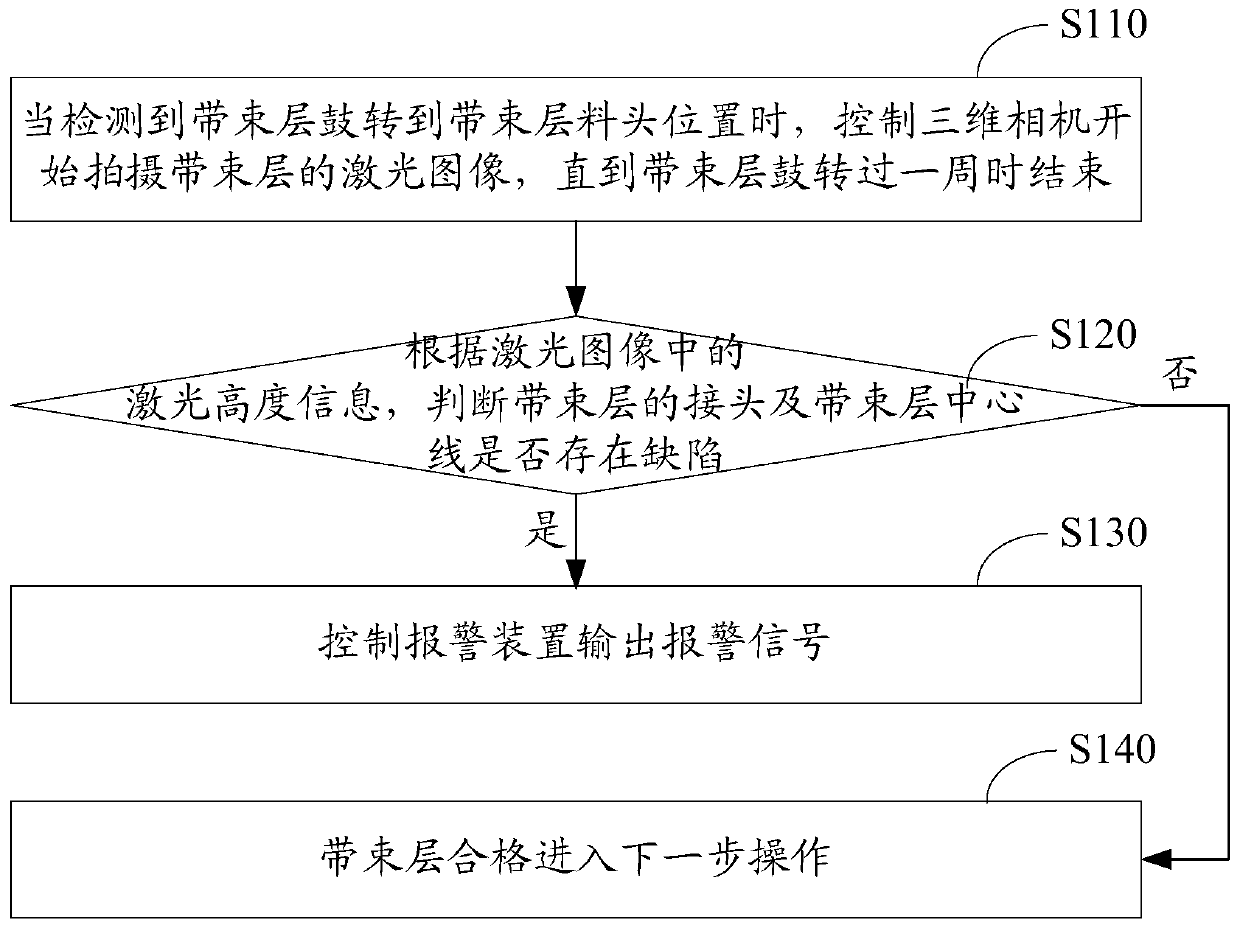

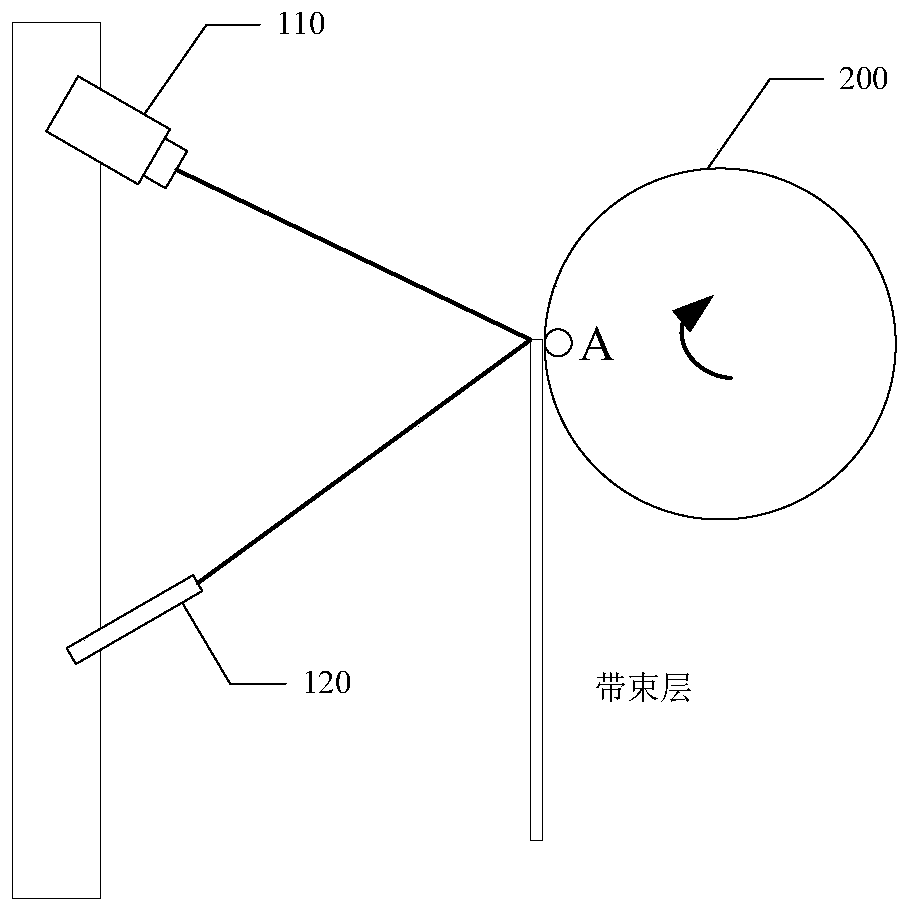

[0076] see figure 1 , is a schematic diagram of a belt defect detection system provided by an embodiment of the present invention, the belt defect detection system is used to automatically detect the belt layer when the tire building machine completes the process of bonding the belt layer Whether there are defects in joints and centerlines.

[0077] Such as figure 1 As shown, the belt defect detection system includes a three-dimensional camera 110 , a laser 120 , a controller 130 and an alarm device 140 .

[0078] The instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com