Railway train wheel set surface defect detection method based on deep learning

A defect detection and deep learning technology, applied in neural learning methods, image enhancement, instruments, etc., can solve the problems of poor and reduced defect recognition accuracy for small targets, avoid missed detection of subtle defects, improve detection accuracy, and avoid complex features. The effect of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

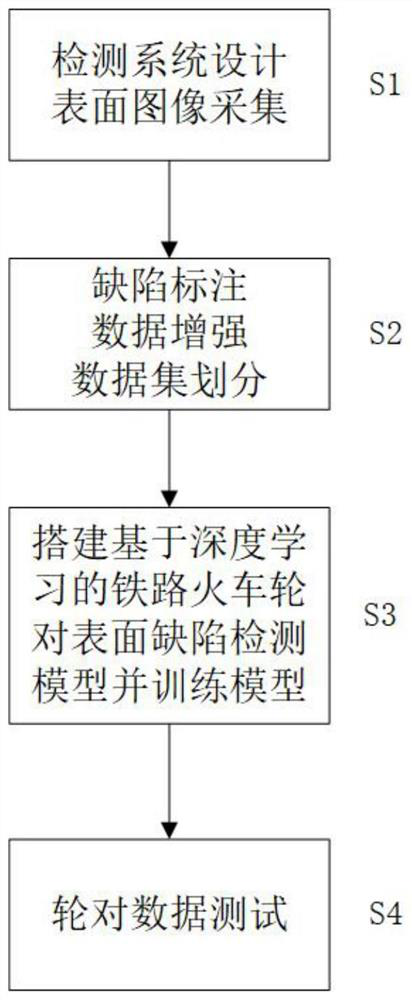

[0033] like Figure 1 to Figure 4 As shown, the method for detecting surface defects of railway train wheels based on deep learning of the present invention includes the following processes:

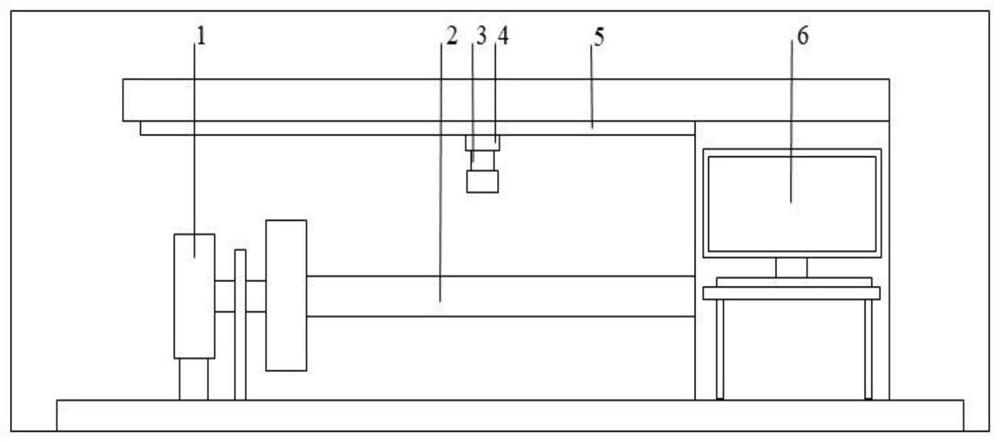

[0034] (1) The surface image of railway train wheelset 2 is collected by the train wheelset surface defect detection system; the surface defect detection system is composed of hardware and software. The hardware includes an industrial camera 3, a stepping motor 4, an image capture card, a rotating mechanism 1, a sliding guide 5 and an industrial computer 6. The stepper motor 4 drives the industrial camera 3 to move in translation on the guide rail mechanism 1, so as to realize the image acquisition on the horizontal line of the railway train wheelset.

[0035] The angle adjustment of the image acquisition of railway train wheelset is realized by the rotation mechanism 1. Whenever the industrial camera completes the image acquisition on a horizontal line, the rotation mechanism 1 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com