Sulfurized natural unsaturated phenol modified fatty acid sulfur-containing zinc soap salt as well as preparation method and application thereof

An unsaturated fatty acid and unsaturated technology, which is applied in the field of vulcanized natural unsaturated phenol modified fatty acid sulfur-containing zinc soap salt and its preparation, can solve the problems of reducing the service life of rubber products and the decline in the performance of rubber products, and achieve the improvement of mechanical properties. The effect of performance, simple process flow and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

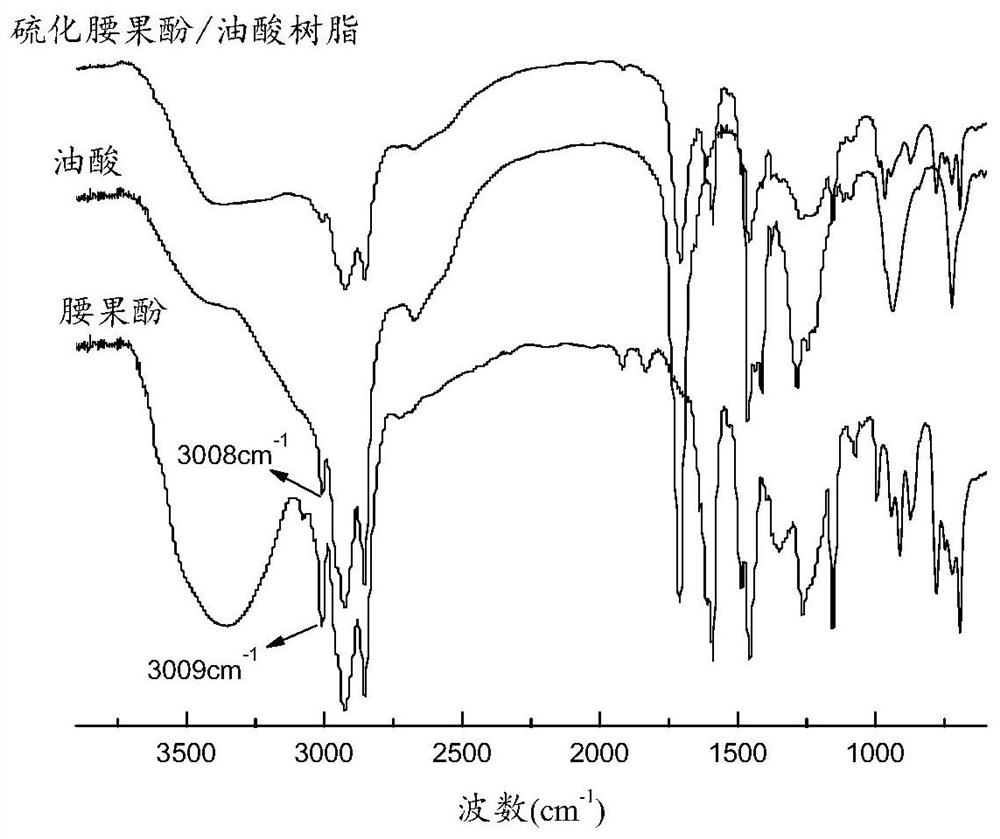

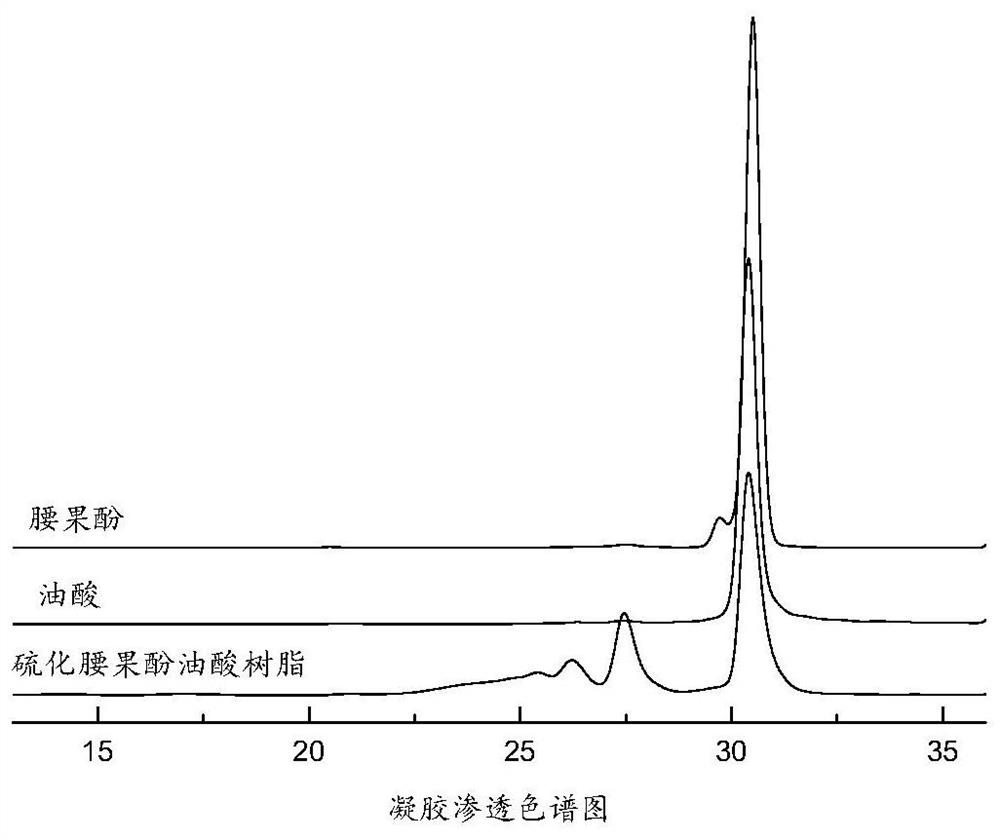

Embodiment 1

[0064] Add 30.0g of cardanol, 28.2g of oleic acid and 3.2g of sulfur into a 500ml round bottom flask equipped with stirring, temperature control, reflux condenser and dropping funnel, protect with nitrogen, react at 165°C for 4h, absorb the tail gas with distilled water, sample It is a black viscous liquid; after cooling down, add 28.4g of stearic acid to mix, then add 5.4g of zinc oxide, and react at 135°C for 1h; then add 2.7g of zinc oxide, react at 135°C for 2.5h, stop the reaction, and you can get vulcanization Cardanol-modified fatty acid sulfur-containing zinc soap salt: Pour out the hot vulcanized cardanol-modified fatty acid sulfur-containing zinc soap salt, and cool to obtain a sulfur-containing zinc soap salt solid, which is bagged and granulated.

Embodiment 2

[0066] Add 15.0g of cardanol, 28.2g of oleic acid and 3.2g of sulfur into a 500ml round bottom flask equipped with stirring, temperature control, reflux condenser and dropping funnel, under nitrogen protection, react at 165°C for 4h, absorb the tail gas with distilled water, sample It is a black viscous liquid; after cooling down, add 28.4g of stearic acid to mix, then add 5.4g of zinc oxide, and react at 135°C for 1h; then add 2.7g of zinc oxide, react at 135°C for 1.5h, stop the reaction, and you can get vulcanization Cardanol-modified fatty acid sulfur-containing zinc soap salt: Pour out the hot vulcanized cardanol-modified fatty acid sulfur-containing zinc soap salt, and cool to obtain a sulfur-containing zinc soap salt solid, which is bagged and granulated.

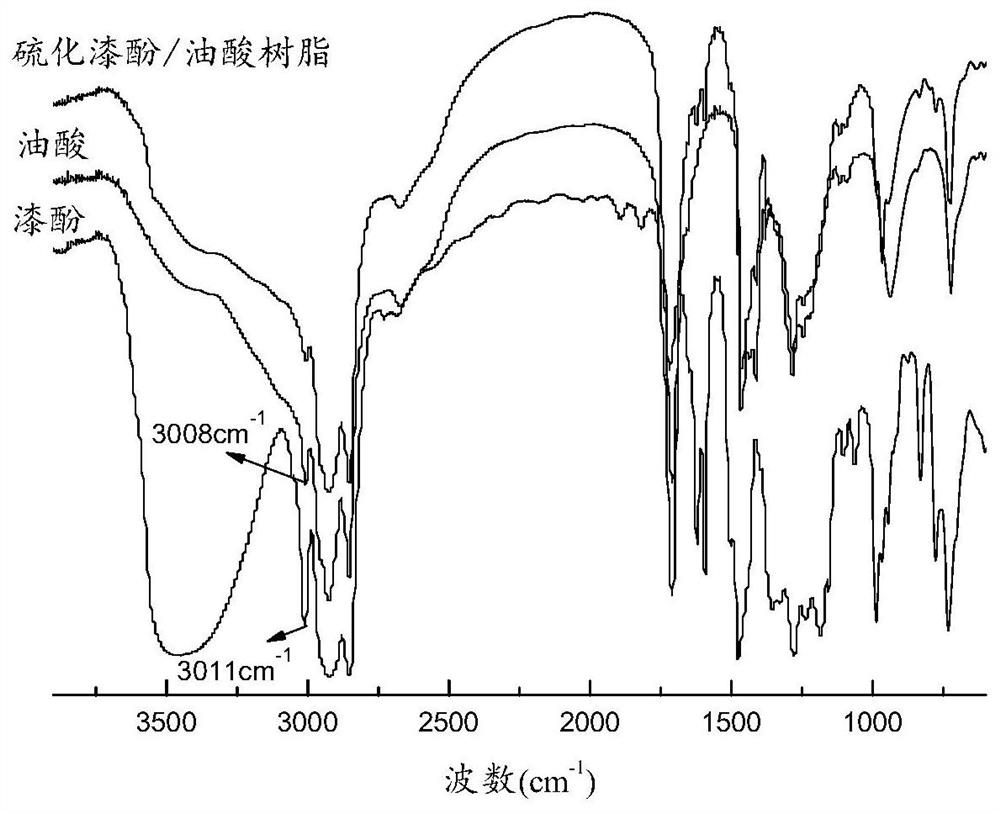

Embodiment 3

[0068] Add 33.0g urushiol, 28.2g oleic acid and 3.2g sulfur to a 500ml round bottom flask equipped with stirring, temperature control, reflux condenser and dropping funnel, protect with nitrogen, react at 165°C for 4h, absorb the tail gas with distilled water, sample It is a black viscous liquid; after cooling down, add 28.4g of stearic acid to mix, then add 5.4g of zinc oxide, and react at 135°C for 1h; then add 2.7g of zinc oxide, react at 135°C for 1.5h, stop the reaction, and you can get vulcanization Urushiol-modified fatty acid sulfur-containing zinc soap salt; pour out the hot sulfurized urushiol-modified fatty acid sulfur-containing zinc soap salt, and cool to obtain a sulfur-containing zinc soap salt solid, which is bagged and granulated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com