Coating brazing filler metal and preparation method and application thereof

A technology of brazing filler metal and coating, applied in the field of coating filler metal and its preparation, can solve the problems of high energy utilization rate, fast melting speed, long heating time, etc., and achieve high energy utilization rate, fast melting speed and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

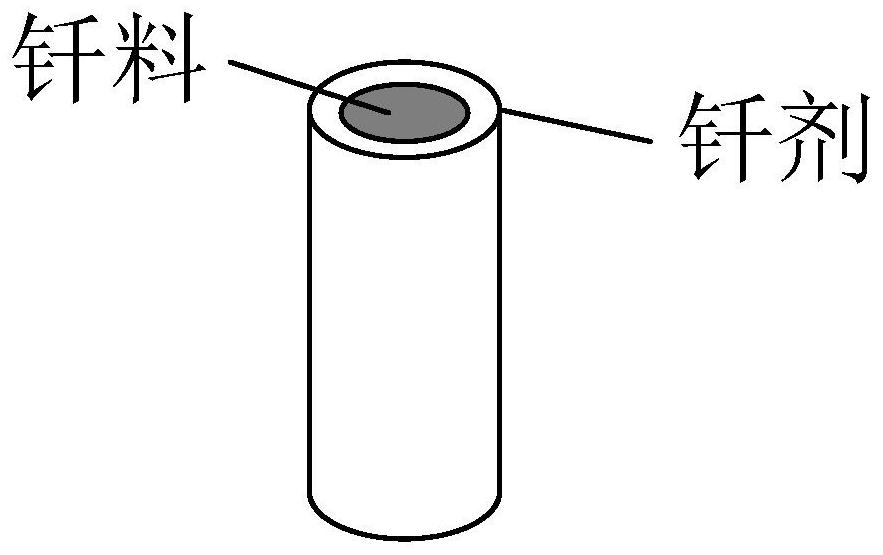

[0064] According to another aspect of the present invention, the present invention also relates to the preparation method of the above-mentioned coated solder, comprising the following steps:

[0065] Dip the brazing material inner core into the mixed molten liquid of the brazing flux and the pore-forming agent, take it out and cool it.

[0066] The coated solder of the present invention forms a pore-structured flux layer by adding a pore-forming agent to the flux. During the welding process, the flux has a fast melting speed and a high energy utilization rate, which can reduce welding time, speed up production tempo, and improve production efficiency.

[0067] The preparation method of the traditional Chinese medicine sheathed brazing filler metal of the present invention is simple and convenient to operate, does not need to add additional binder, just can realize that brazing flux adheres to the brazing filler metal surface, forms uniform brazing flux film; The molten flux i...

Embodiment 1

[0087] A preparation method of covered brazing material, comprising the following steps:

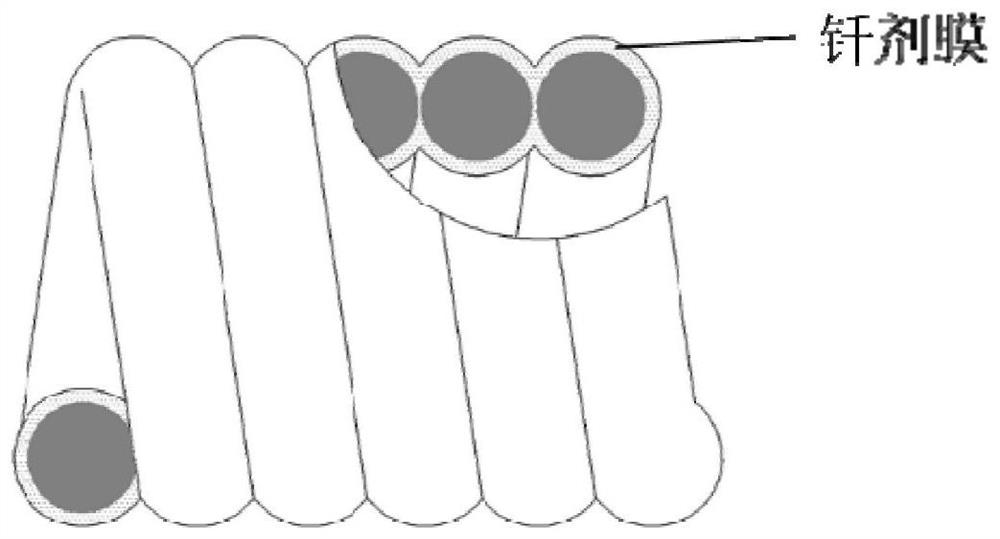

[0088] (a) Prepare the BAg45CuZn brazing material inner core by smelting, extrusion, rolling / drawing, annealing and other processing methods into a main body wound into a spiral ring with a hollow structure;

[0089] (b) Put the brazing flux, pore-forming agent and pore-forming agent in a stirrer, stir for 1.5 hours, take it out and place it in a container of ceramic material or graphite material, and heat it at 250°C to ensure that the braze The agent is in the viscous state of partial melting to avoid excessive gas escape; the pore-forming agent is ammonium bicarbonate, and the brazing flux is a mixture of fluoroborate, fluoride and boron gangue, and the fluoroborate , the mass ratio of fluoride, boron gangue and ammonium bicarbonate is 33:19:28:20;

[0090] (c) Place the inner core of the brazing material in the flux melt, and require the molten brazing flux to be submerged in the br...

Embodiment 2

[0095] A preparation method of covered brazing material, comprising the following steps:

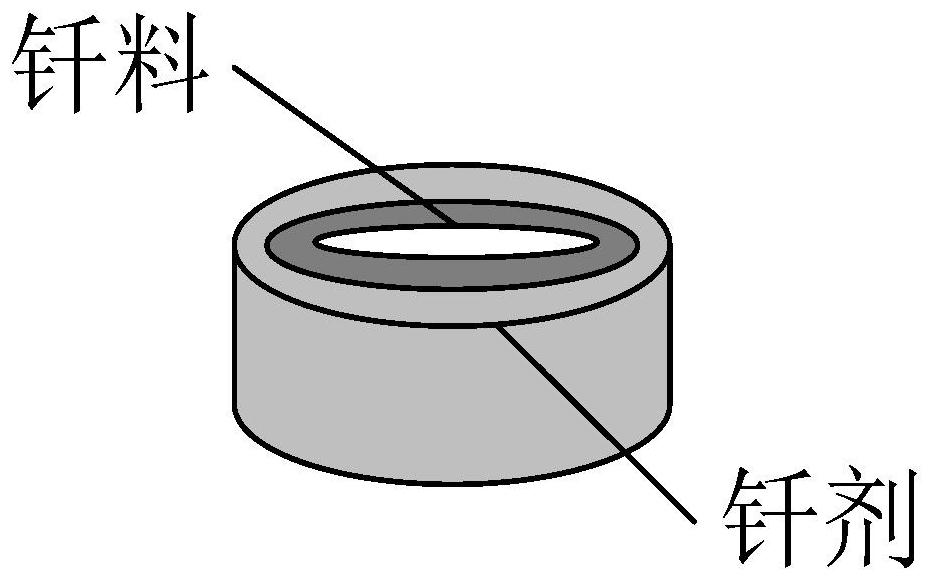

[0096] (a) Prepare the BCu58ZnMn solder inner core into a ring shape with a hollow structure by using smelting, extrusion, rolling / drawing, annealing and other processing methods;

[0097] (b) Put the brazing flux, pore-forming agent and pore-forming agent in a stirrer, stir for 2 hours, take it out and place it in a container made of ceramic material or graphite material, and heat it at 350°C to ensure that the brazing flux Be in the viscous state of partial melting, avoid too much escape of gas; The pore-forming agent is polyethylene glycol, phenolic resin, and the brazing flux is a mixture of borate, boric acid and boron gangue, and the borate , boric acid and boron gangue, polyethylene glycol, the mass ratio of phenolic resin is 35:12:23:5:25;

[0098] (c) Place the brazing material inner core in the brazing flux melt, require the molten brazing flux to be submerged in the brazing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com