Rail car fuel oil monitoring system and method

A monitoring system and technology for rail cars, applied in the field of rail car fuel monitoring systems, can solve problems such as increasing fuel costs, falsely reporting fuel consumption, and reselling fuel, and achieve the effects of reducing wasteful behavior, reducing fuel costs, and realizing interconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

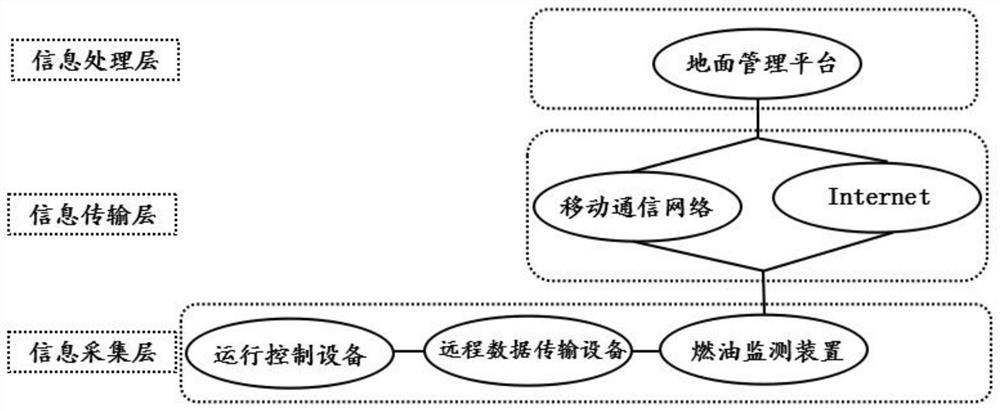

[0053] like figure 1 As shown, this embodiment shows a rail car fuel monitoring system, which is composed of an information collection layer, an information transmission layer, and an information processing layer, wherein the information collection layer is used to collect fuel monitoring data and public information, and jointly transmit the fuel monitoring data and the public information to the information processing layer; the information transmission layer is used to provide a communication network for the transmission of the fuel monitoring data and the public information, and the communication network includes mobile A communication network and an Internet network; the information processing layer is a ground management platform, and the ground management platform is used to receive the monitoring data and the public information, and conduct comprehensive analysis on the monitoring data and the public information.

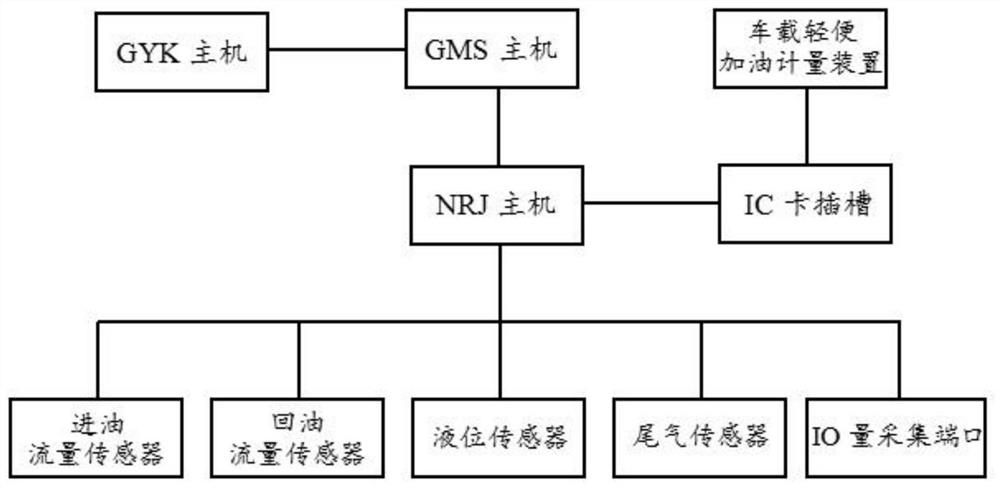

[0054] Specifically, the information collection layer in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com