Automobile exhaust particulate matter adsorption device

A technology for adsorption devices and automobile exhaust, which is applied in the direction of exhaust devices, mufflers, engine components, etc., can solve the problems of poor discharge uniformity, poor safety of ultra-high voltage compatibility, and reduced service life of equipment, so as to achieve low discharge operating voltage and convenient Layout and installation to achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

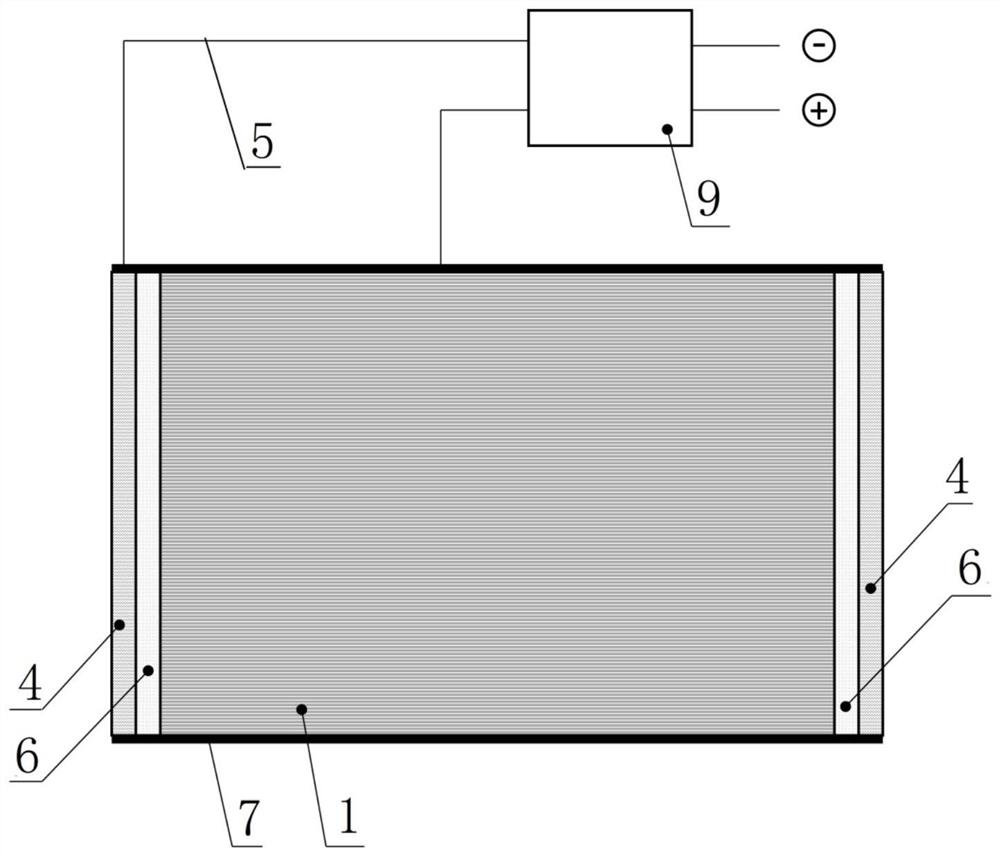

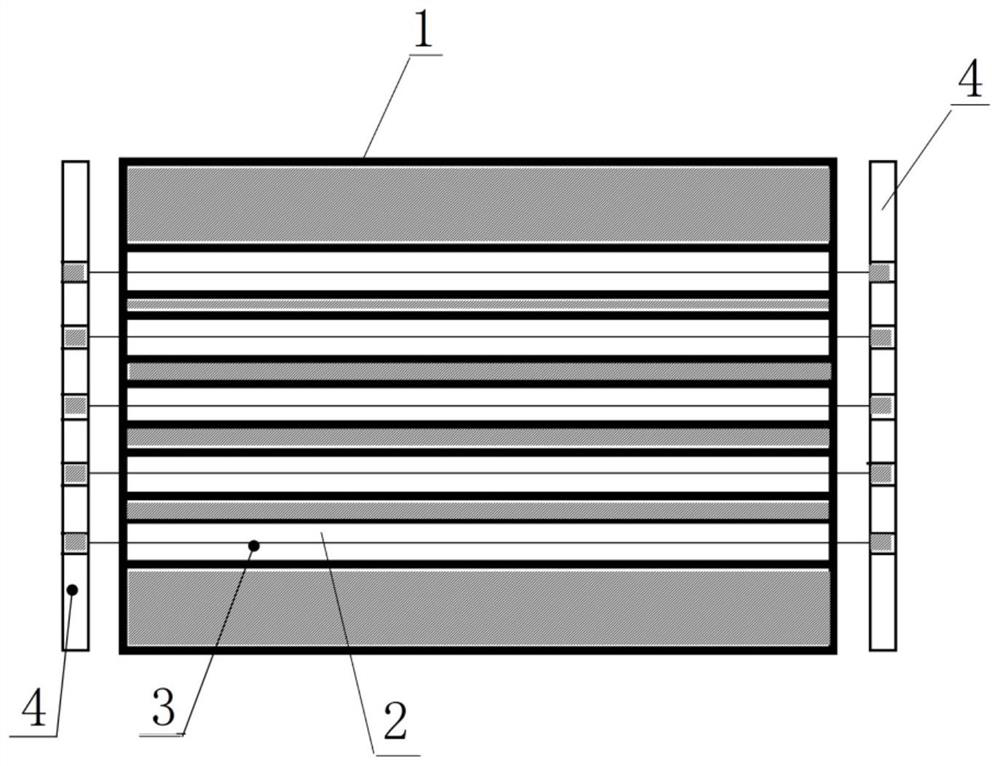

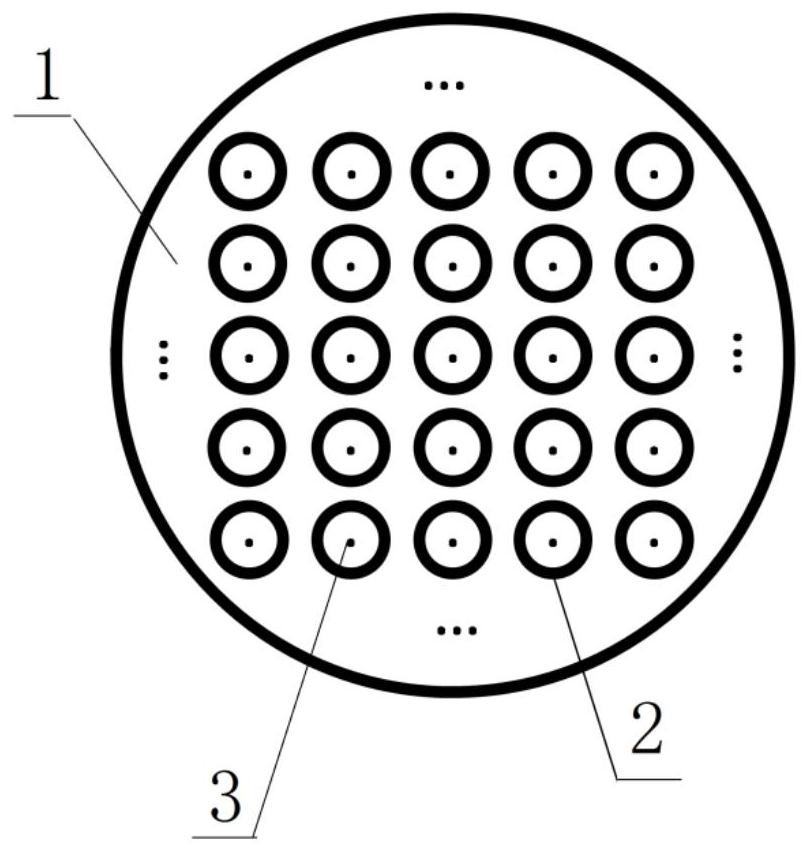

[0028] Such as figure 1 , figure 2 and image 3 As shown, the automobile exhaust particle adsorption device of the present invention includes a particle collector 1, the particle collector 1 is made of a conductive material, and the inside of the particle collector 1 is provided with several first ones spaced apart from each other and arranged in an array along the exhaust direction. Air vent 2, the first air vent 2 is a circular hole, such as Figure 4 As shown, the hole wall of the first ventilation hole 2 is provided with several thorns 8 arranged at intervals, and the thorns 8 are evenly arranged at equal intervals on the hole wall of the first ventilation hole 2, and the first ventilation hole 2 is exhausted. Direction runs through both ends of the particle collector 1, the vent hole 2 is pierced with a discharge wire 3 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com