Genetically engineered bacterium for producing hydroxyectoine and application of genetically engineered bacterium

A technology of hydroxytetrahydropyrimidine and genetic engineering bacteria, applied in the field of genetic engineering, can solve the problems of long production cycle, high market price, low yield, etc., and achieve the effect of high-efficiency synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Construction of E.coli W3110 Hydroxytetrahydropyrimidine Genetically Engineered Bacteria

[0048] Targeted gene modification using CRISPR / Cas9 gene editing technology. The gene editing method adopted in the present invention is carried out with reference to the literature (Li Y, Lin Z, Huang C, et al. Metabolic engineering of Escherichiacoli using CRISPR-Cas9 meditated genome editing. Metabolic engineering, 2015, 31:13-21.).

[0049] The specific steps of this method are as follows:

[0050] (1) Construction of pGRB plasmid:

[0051] Use CRISPR RGEN Tools to design a specific target sequence ((PAM: 5'-NGG-3') for cutting the target gene. After synthesizing forward primer and reverse complementary primer, take 10 μL of each into a PCR tube, and mix them evenly. A double-stranded fragment was formed by annealing single-stranded DNA by PCR. Reaction conditions: pre-denaturation at 95° C., 5 min; The pGRB plasmid was obtained. The kit used for homologous recom...

Embodiment 2

[0077] Example 2: The method for producing hydroxytetrahydropyrimidine by using the hydroxytetrahydropyrimidine genetically engineered bacteria obtained in step (2) in Example 1 to knock out the yeeL gene and integrate icd by shaking flask fermentation

[0078] (1) Activated slant culture: use an inoculation loop to inoculate 1-2 loops of bacteria from the -80°C refrigerator storage tube, spread evenly on the slant medium, cultivate at 37°C for 12 hours, and transfer to the second-generation slant medium , cultured at 37°C for 12h;

[0079] (2) Seed bottle culture: use an inoculation loop to inoculate the bacterial cells on the inclined surface into a 500mL conical flask containing 30 mL of seed medium for the preparation of seed liquid. Shake culture for 12h under the condition of min;

[0080] (3) Fermentation culture: the seed liquid was inoculated into a 500mL baffle bottle containing a fermentation medium according to 10% of the inoculum, so that the final volume was 30mL,...

Embodiment 3

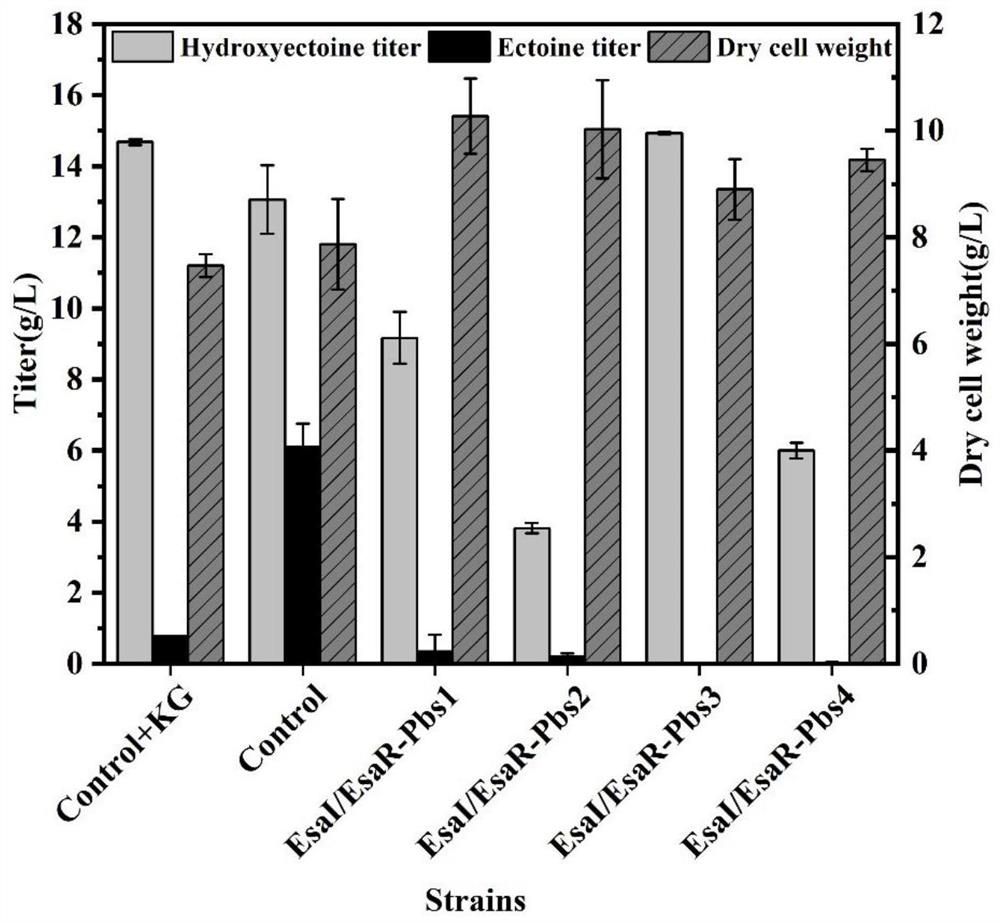

[0085] Embodiment 3: utilize esaI / esaR quorum sensing circuit engineering bacteria shake flask fermentation method to produce hydroxytetrahydropyrimidine

[0086] (1) Activated slant culture: use an inoculation loop to inoculate 1-2 loops of bacteria from the -80°C refrigerator storage tube, spread evenly on the slant medium, cultivate at 37°C for 12 hours, and transfer to the second-generation slant medium , cultured at 37°C for 12h;

[0087] (2) Seed bottle culture: use an inoculation loop to inoculate the bacterial cells on the inclined surface into a 500mL conical flask containing 30 mL of seed medium for the preparation of seed liquid. Shake culture for 12h under the condition of min;

[0088] (3) Fermentation culture: the seed liquid was inoculated into a 500mL baffle bottle containing a fermentation medium according to 10% of the inoculum, so that the final volume was 30mL, sealed with twelve layers of gauze, at 37°C, 180r / min Under the condition of shaking culture, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com