Kitchen waste automatic residue discharging and oil separating equipment

A kind of kitchen waste and automatic technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor utilization of waste oil, lack of good recycling devices, machine jamming, etc., to achieve complete functions and structural The effect of compactness and high structural utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

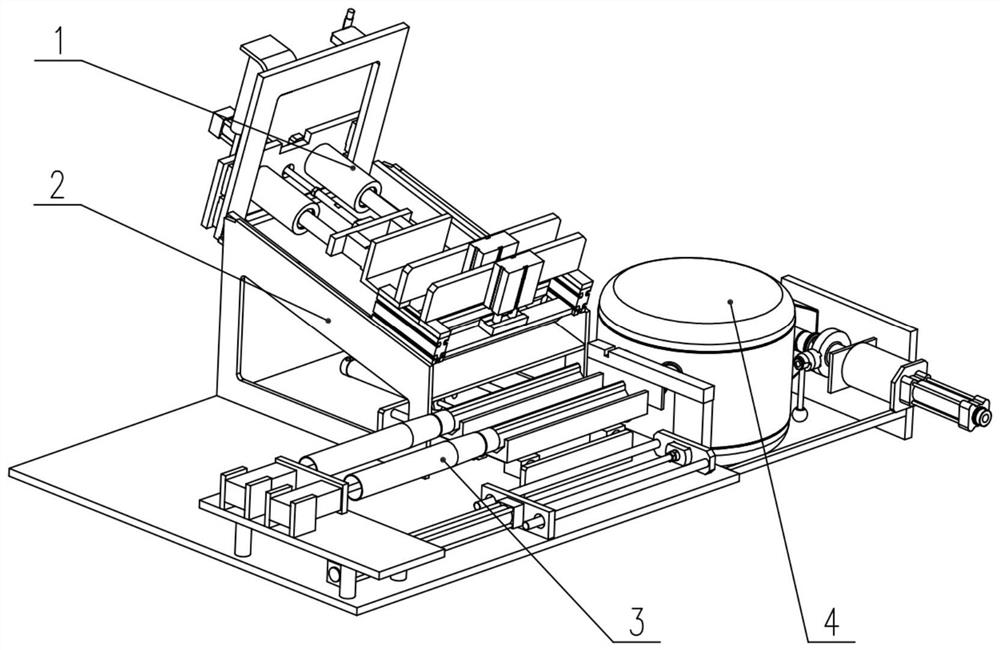

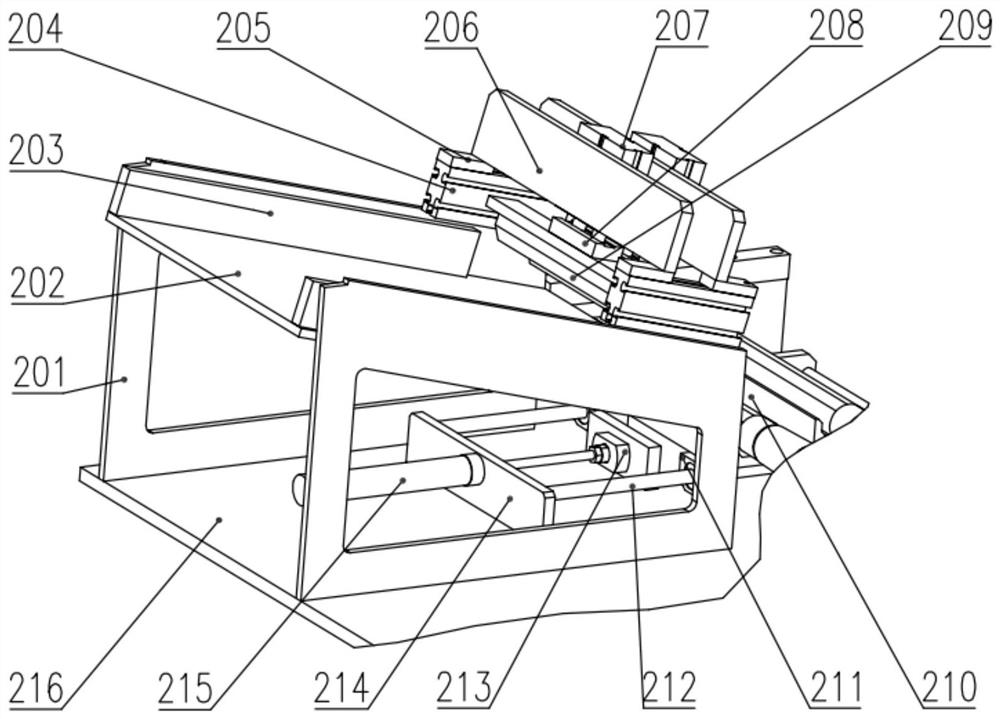

[0022]Example:figure 1 ,figure 2 ,image 3 ,Figure 4 ,Figure 5A kitchen garbage is automatically slag, including a push device 1, a partitioning device 2, a scraping device 3, a fuel supply device 4.

[0023]A specific structure of a kitchen garbage automatic slag gasifer equipment such asfigure 1 As shown in, there is, in which the pusher 1 is fixed to the separator 2, the separator 2 is fixedly mounted on the ground, and the scraping device 3 is fixed to the partitioning device 2, and the oil collecting device 4 is fixedly mounted on the separator 2, will The kitchen waste poured into a kitchen garbage auto-outdrawing oil, in which the partitioning device 2 is used as a primary load-bearing structure, and the pusher 1, the scraping apparatus 3, and the oil supply device 4 are mounted thereon.

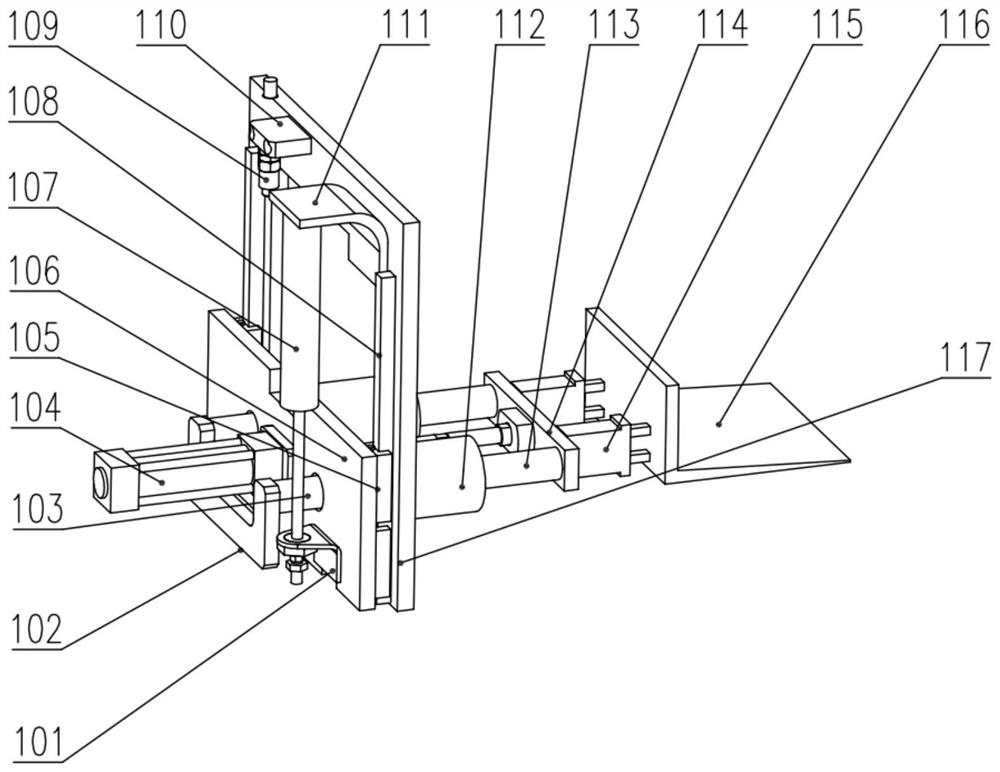

[0024]The specific structure of the pincerization device 1 is likefigure 2 As shown in, the push seat 101 is fixedly mounted on the connecting plate 106, and the pallet 102 is fixed to the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com