Automatic feeding and discharging machine of petroleum pipe threading lathe

A technology of automatic loading and unloading, thread lathe, used in metal processing equipment, tangent devices, manufacturing tools, etc., can solve the problems of thread processing quality and supply of drill pipe and collars, high labor intensity, poor sealing and other problems , to achieve the effect of ensuring exploration, development and production and avoiding stuck drilling and buried drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

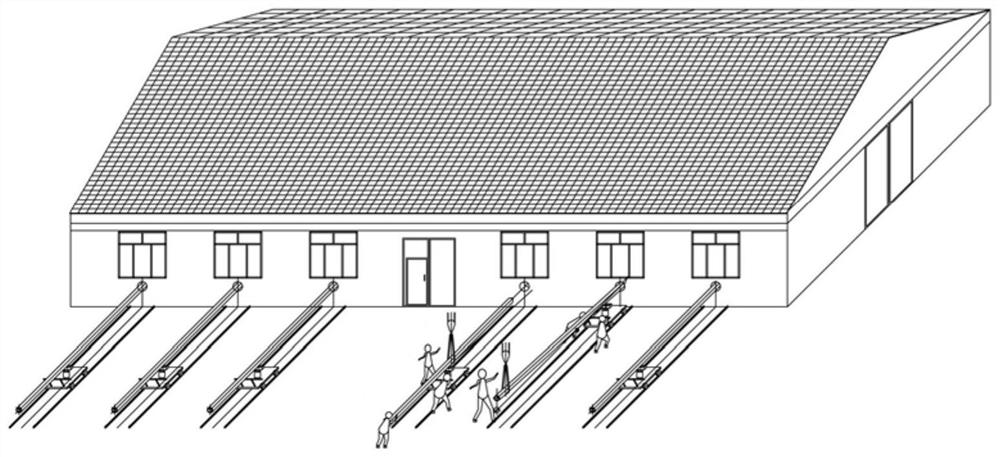

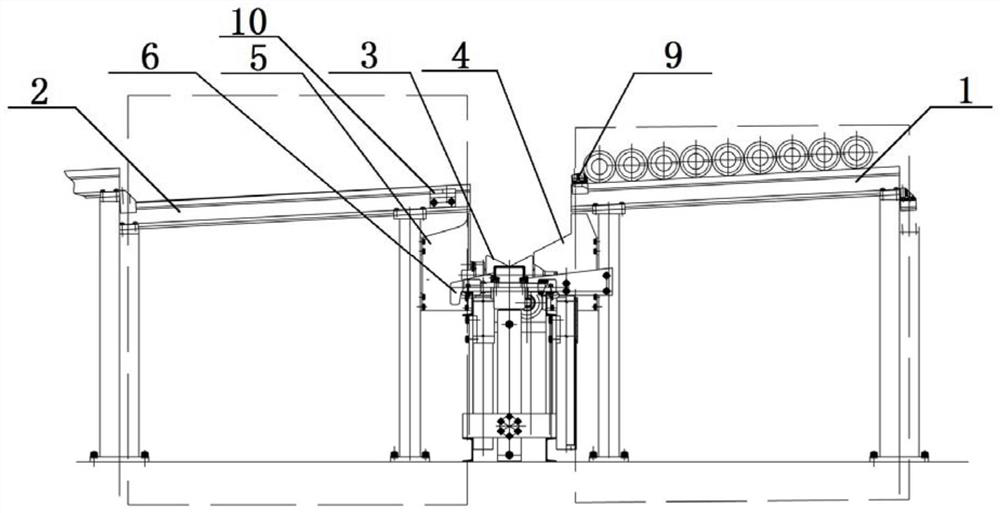

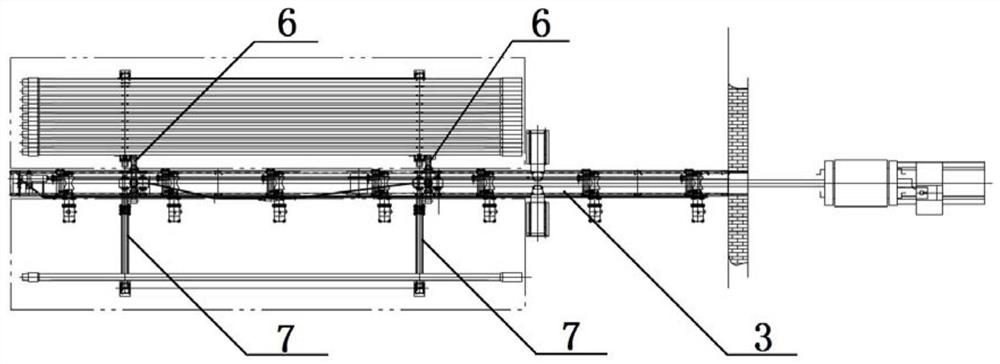

[0073] refer to Figure 2-34 , the automatic loading and unloading machine for oil pipe thread lathe provided by the present invention comprises: loading table area 1, unloading table area 2, roller conveying mechanism 3 between loading table area 1 and unloading table area 2, connecting feeding The feeding deflector 4 of the table area 1 and the roller conveying mechanism 3, the unloading deflector 5 connecting the unloading table area 2 and the roller conveying mechanism 3, installed between the feeding table area 1 and the unloading table area 2 A group of a total of two loading and unloading conveying mechanisms 6; wherein the loading platform area 1 and the unloading platform area 2 are composed of a set of heavy rails 7 and a column 8 supported under the heavy rails 7. Support with inclined surfaces frame, the end of the loading platform area 1 close to the roller conveying mechanism 3 is lower and the end is provided with an adjustment block 9, and the adjustment block ...

Embodiment 2

[0081] In this embodiment, utilizing the rolling characteristics of cylindrical pipes, a loading table area 1 and a feeding table area 2 with an inclined surface are designed to make the pipes roll automatically and orderly on the surface, and the loading and unloading process of the roller conveying mechanism 3 is also used The characteristics of the cylindrical pipe rolling on the inclined surface, on the basis that the pipes on the inclined surfaces of the feeding table area 1 and the unloading table area 2 have automatic rolling to generate displacement, pass through the feeding inclined surface and unloading inclined surface of the upper and lower material plate 601, and the conveying roller The V-shaped slope of 304 completes a series of dynamic position changes of the pipe, forming an automatic loading and unloading block for the pipe.

[0082] In this embodiment, during the loading and unloading process, the pipe material rolls along the inclined surface of the loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com