Abelmoschus manihot flower flavonoid effective part as well as preparation method and application thereof

A technology of flavonoids and effective parts of hollyhocks, which is applied in the field of medicine, can solve the problems of large variation of active ingredient content, low extraction and transfer rate, lack of practical research, etc., and achieves good prevention or treatment of sunscreen, simple process, and good anti-aging effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

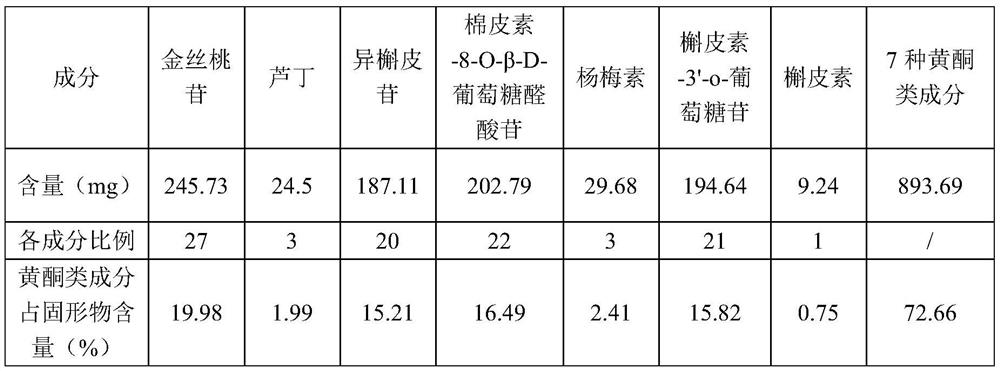

[0041] Example 1 Preparation of effective fractions of flavonoids from hollyhock flower

[0042] Grind 100g of hollyhock flowers into coarse powder, extract with 15 times of 60% ethanol under reflux, and obtain the ambrette extract; after the amber extract is absorbed by activated carbon, filter it with an ultrafiltration membrane with a molecular weight cut-off of 3500, and collect the filtrate , the filtrate is filtered with an ultrafiltration membrane with a molecular weight cut-off of 500 to obtain a concentrated solution, and the concentrated solution is decompressed to recover ethanol at 50 ° C, and then treated with D101 macroporous resin. The treatment process of the macroporous resin is as follows: : The diameter-to-height ratio of the macroporous resin is 1:6, the concentration of the sample solution (aqueous solution) is 0.15g crude drug / ml, the volume of the sample solution is 7BV, and the sample is loaded at a flow rate of 2BV / h, with 6BV of pure water and 3BV of 5...

Embodiment 2

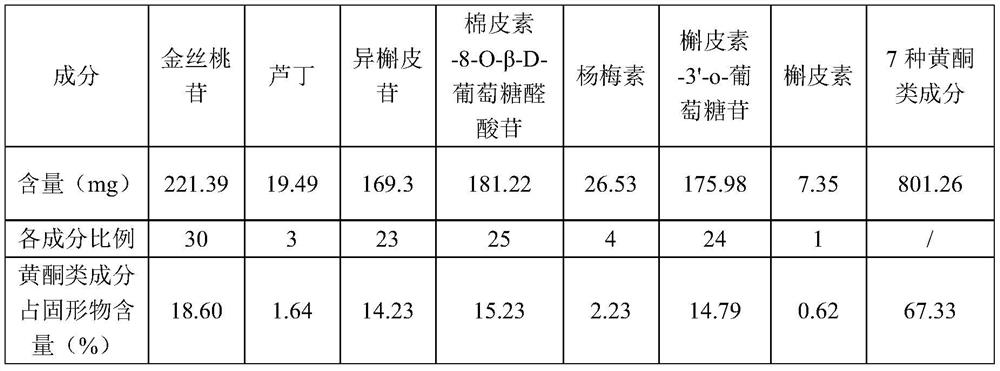

[0043] Example 2 Preparation of effective fractions of flavonoids from hollyhock flower

[0044] Grind 100g of hollyhock flowers into coarse powder, extract with 18 times of 70% ethanol under reflux, and obtain the ambrette extract; filter the amber extract with an ultrafiltration membrane with a molecular weight cut-off of 3500, collect the filtrate, Use an ultrafiltration membrane with a molecular weight cut-off of 1000 to filter out 70% of the liquid to obtain a concentrated solution. After the concentrated solution is decompressed at 60°C to recover ethanol, it is treated with D101 macroporous resin. The treatment process of the macroporous resin is: macroporous resin diameter The height ratio is 1:5, the concentration of the sample solution is 0.15g crude drug / ml, the volume of the sample solution is 6BV, the sample is loaded at a flow rate of 2BV / h, and impurities are removed with 6BV of pure water and 3BV of 5% ethanol at a flow rate of 2BV / h. Elute with 4BV 60% ethanol...

Embodiment 3

[0045] Example 3 Preparation of effective fractions of flavonoids from hollyhock flower

[0046] Grind 100g of hollyhock flowers into coarse powder, extract by percolation with 18 times of 60% ethanol to obtain the ambrette extract; The concentrated solution is obtained by filtering out 80% of the liquid with an ultrafiltration membrane with a molecular weight cut-off of 500. After the concentrated solution is decompressed at 60°C to recover ethanol, it is treated with D101 macroporous resin. The treatment process of the macroporous resin is: macroporous resin The diameter-to-height ratio is 1:8, the concentration of the sample solution is 0.15g crude drug / ml, the volume of the sample solution is 8BV, the sample is loaded at a flow rate of 2BV / h, and impurities are removed with 6BV of pure water and 3BV of 5% ethanol at a flow rate of 2BV / h , 4BV 60% ethanol was used to elute with a flow rate of 3BV / h to obtain an eluate, and the eluate was recovered under reduced pressure at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com