Heat-conducting wave absorber as well as preparation method and application thereof

A wave absorber, integrated technology, applied in cooling/ventilation/heating transformation, electrical components, magnetic field/electric field shielding and other directions, can solve problems such as low thermal conductivity and thickness space influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

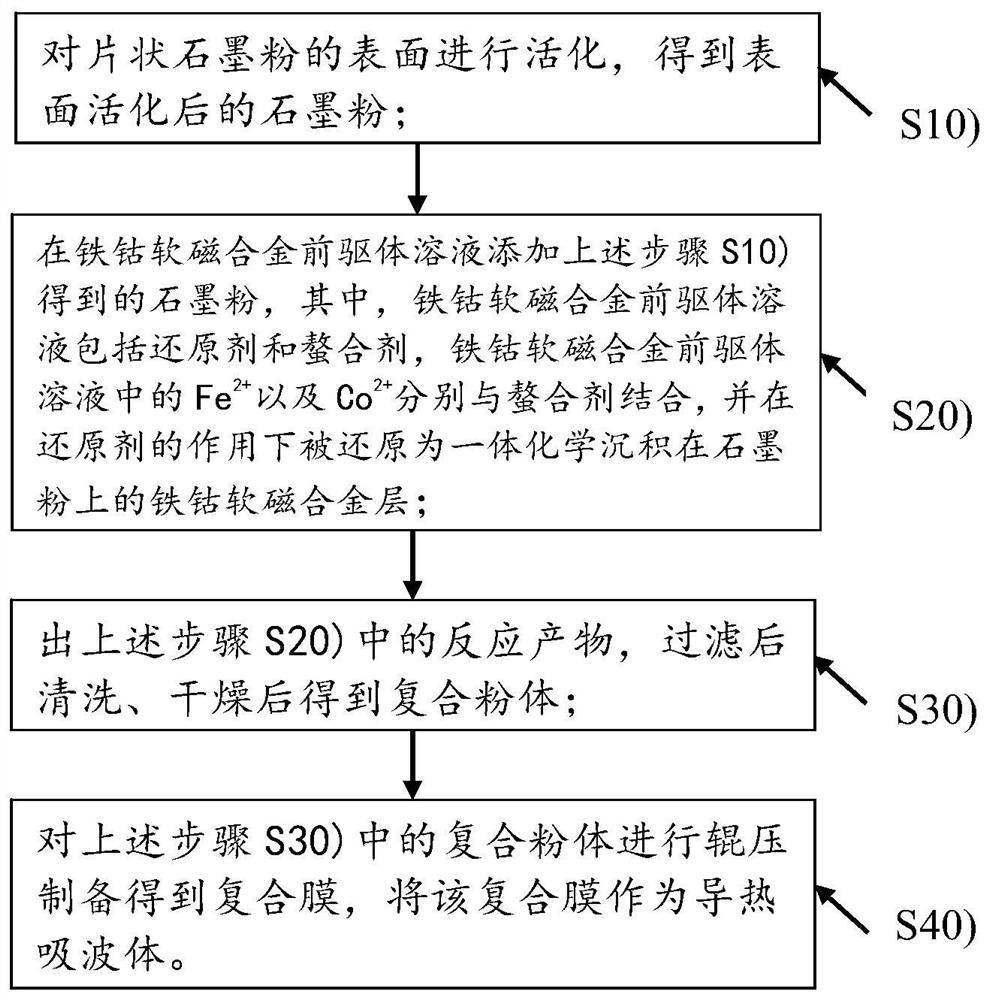

[0026] The embodiment of the present invention also discloses a method for preparing a heat-conducting absorber, which includes the following steps:

[0027] S10), the surface of flake graphite powder is activated to obtain the graphite powder after surface activation;

[0028] S20), adding the graphite powder obtained in the above steps S10) to the iron-cobalt soft magnetic alloy precursor solution, wherein the iron-cobalt soft magnetic alloy precursor solution includes a reducing agent and a chelating agent, Fe in the iron-cobalt soft magnetic alloy precursor solution 2+ and Co 2+ Combined with chelating agent respectively, and under the action of reducing agent, it is reduced into one iron-cobalt soft magnetic alloy layer chemically deposited on graphite powder;

[0029] S30), taking out the reaction product in the above step S20), filtering, cleaning and drying to obtain a composite powder;

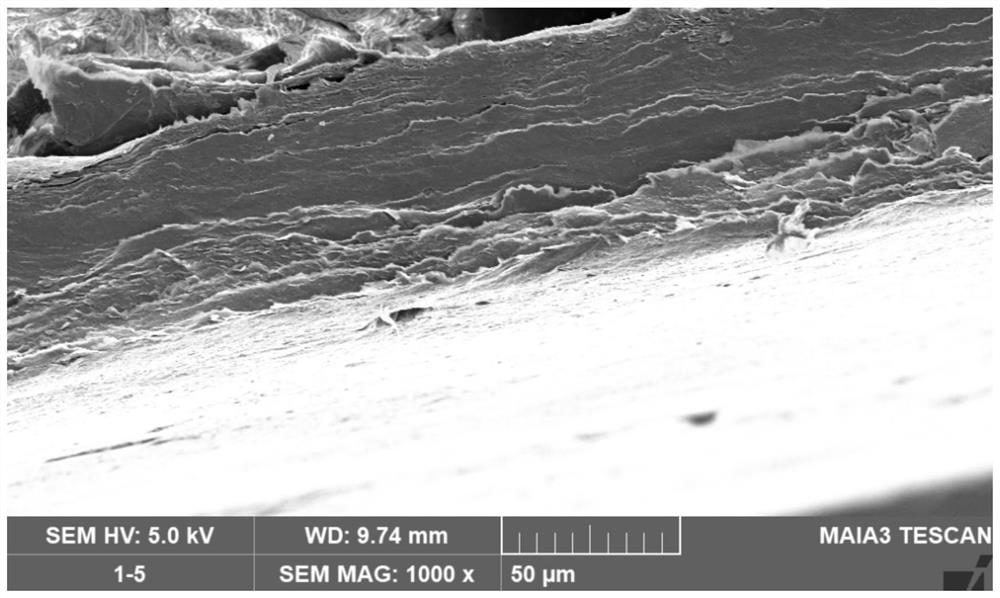

[0030] S40), the composite powder in the above step S30) is rolled to prepare a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com