Design method of catadioptric deep ultraviolet lithography objective lens system

A technology of deep ultraviolet light and system design, applied in microlithography exposure equipment, opto-mechanical equipment, optics, etc., can solve the problems of difficult initial structure design, complex structure, etc., to improve design efficiency, reduce design complexity, The effect of reduced time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below with reference to the accompanying drawings and examples.

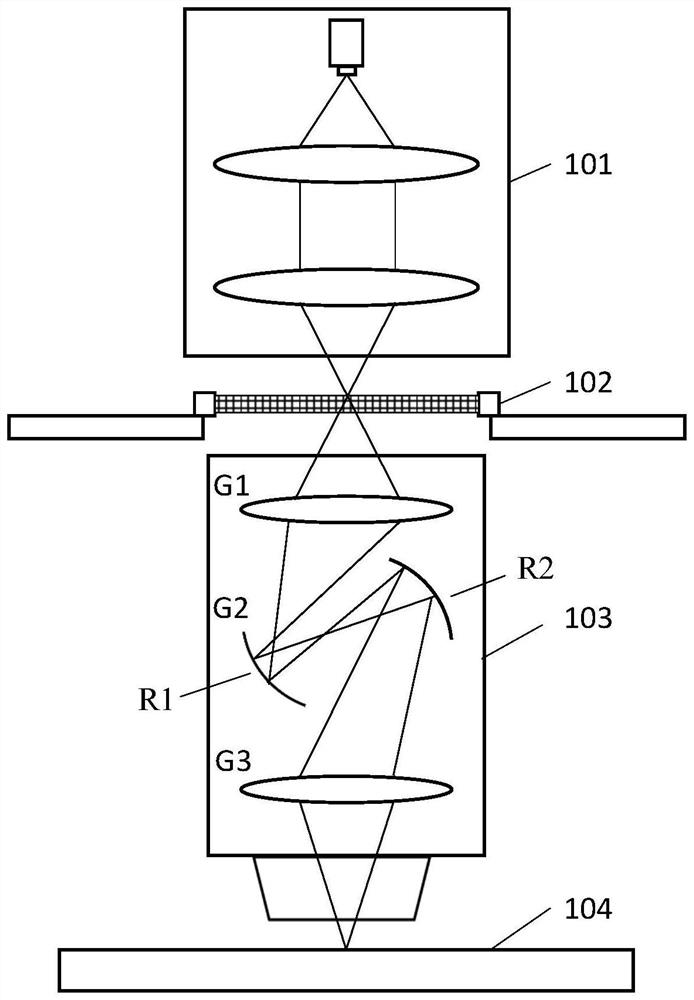

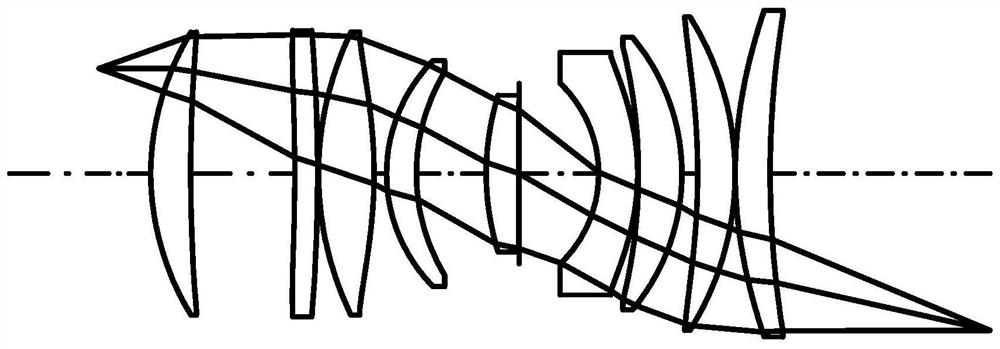

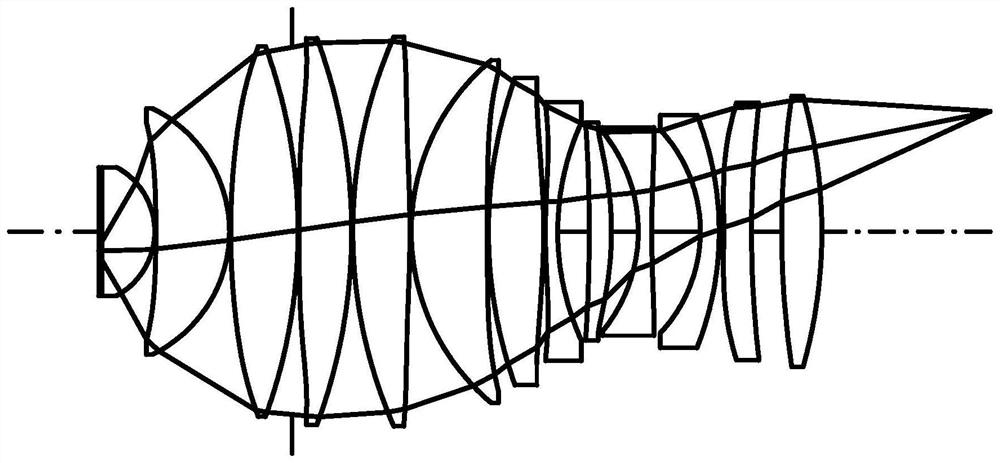

[0058] Such as figure 1 As shown, the present invention proposes a catadioptric deep-ultraviolet lithography objective lens system and design method. The lithography projection objective lens system includes an object square mirror group G1, an intermediate mirror group G2, and an image square mirror group G3. The structure of the objective lens system is complex and the design It is very difficult, so the initial structure design is carried out through group compounding and iterative design methods. Using this method, the initial structure of the catadioptric DUV lithography objective lens system can be obtained quickly and efficiently. DUV lithography objective system.

[0059] The working process of the deep ultraviolet projection lithography objective lens of the present invention is as follows: the light emitted by the illumination system 101 is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com