Planet cone gear type continuously variable transmission

An automatic transmission and bevel wheel technology, which is applied in the direction of vehicle gearboxes, gear transmissions, transmission components, etc., can solve the problem of contact surfaces between easily damaged small friction wheels and input and output bevel wheels, reduce the transmission efficiency of the transmission, and shorten the transmission Service life and other issues, achieve uniform load distribution between gear teeth, reduce volume and weight, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

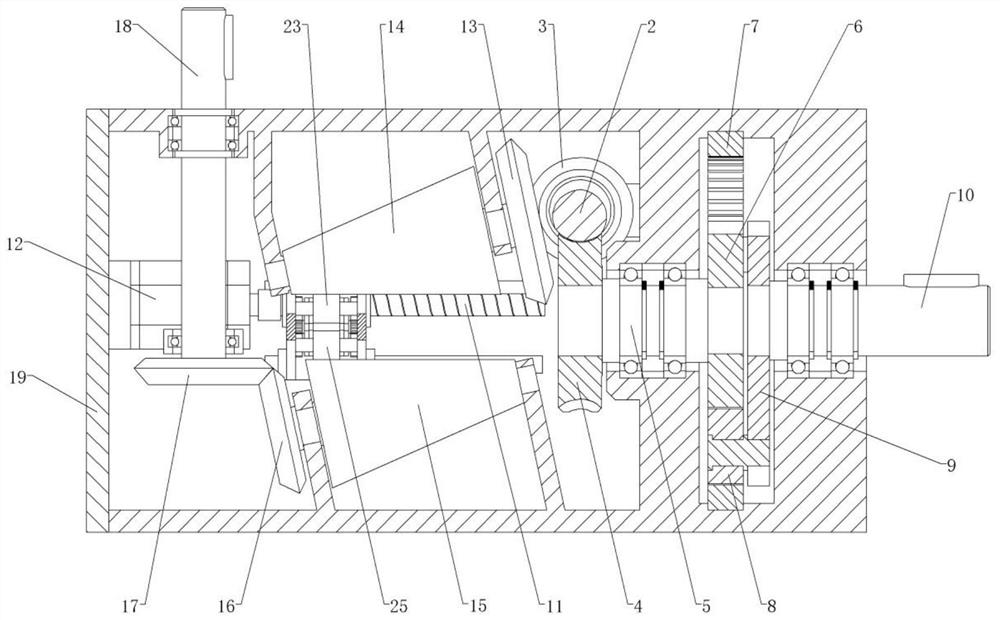

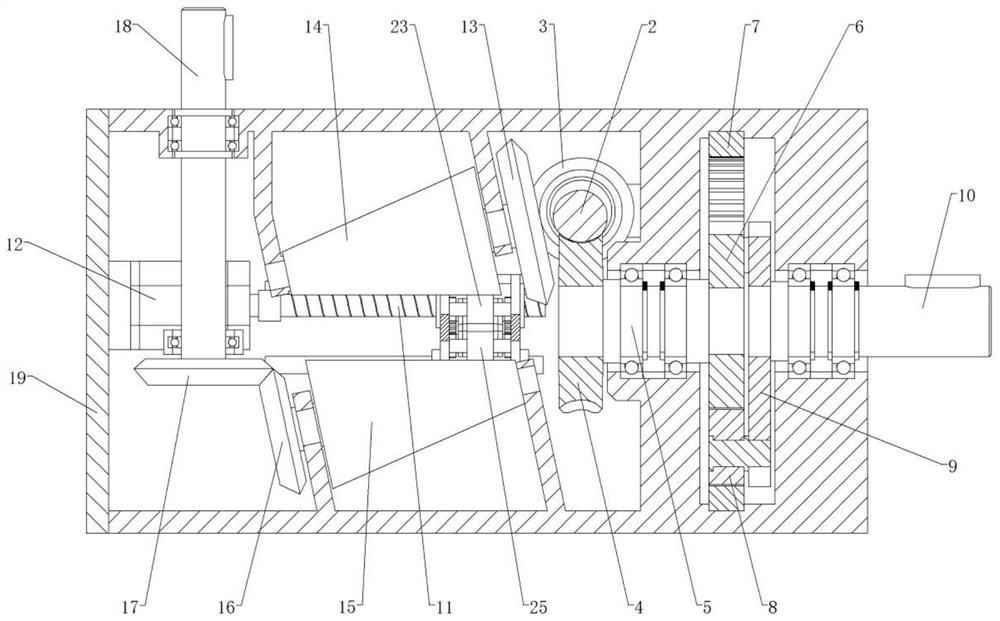

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

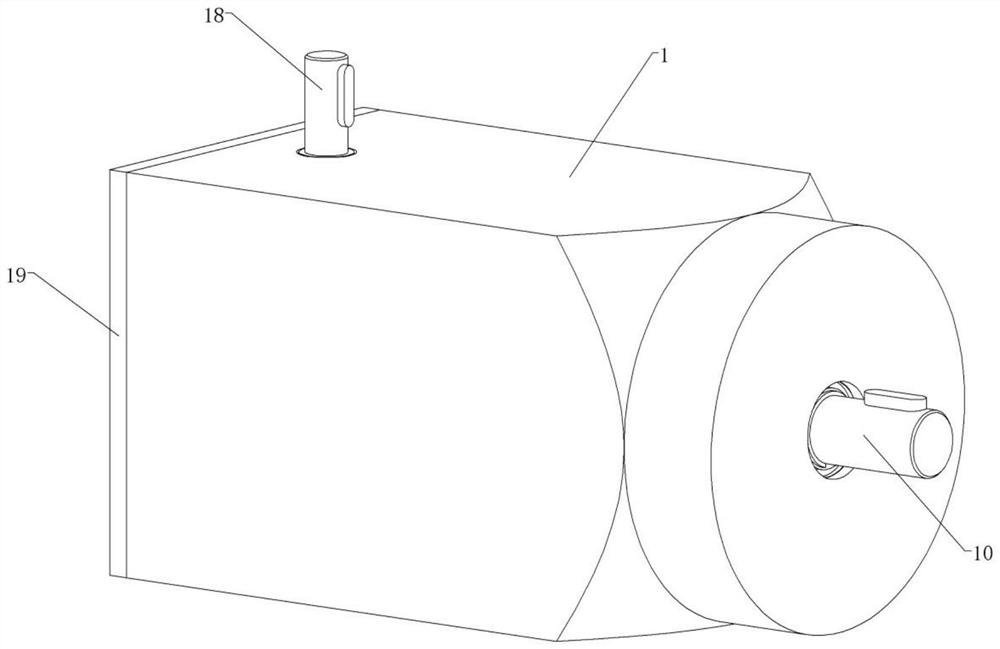

[0031] Such as Figure 1 to Figure 8 As shown, a planetary bevel gear type continuously variable automatic transmission includes a casing 1, a worm 2, a fourth bevel gear 3, a worm gear 4, a central shaft 5, a central gear 6, an inner ring gear 7, a planetary gear 8, and a planet carrier 9 , output shaft 10, threaded rod 11, motor 12, third bevel gear 13, second transmission bevel wheel 14, first transmission bevel wheel 15, second bevel gear 16, first bevel gear 17, input shaft 18, sealing cover 19. Sliding frame 20, cylinder 21, first holding rod 22, driven wheel 23, driven gear 23.1, second holding rod 24, transmission gear 24.1, driving wheel 25, driving gear 25.1, holding piece 26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com